Low-temperature deposition device and process for TCO film

A transparent conductive film and deposition device technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems of high power consumption, high equipment operation cost, glass breakage, etc., and achieve equipment failure rate Low cost, reduced processing cost, simplified equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

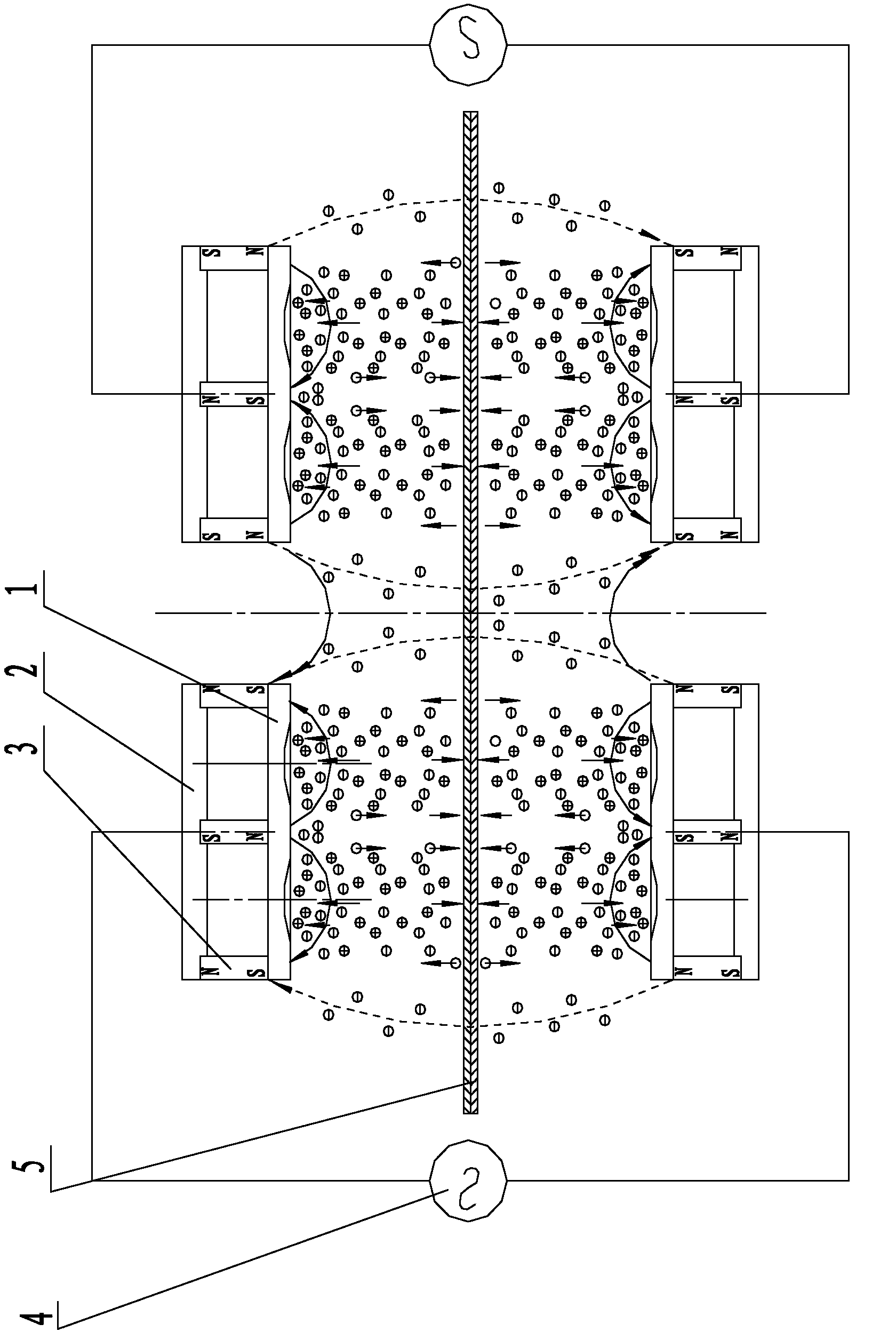

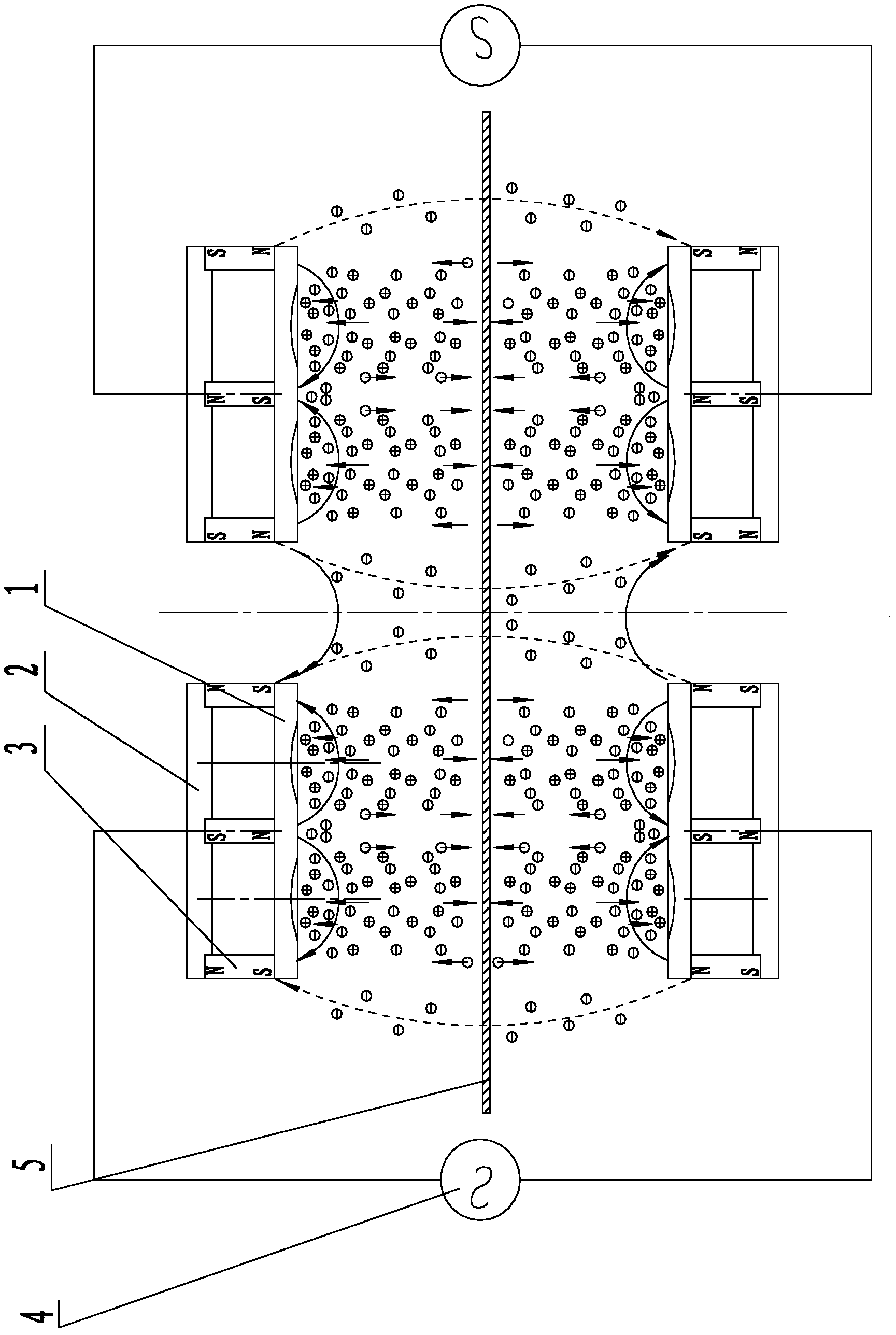

[0043]This embodiment is a low-temperature deposition device of a TCO transparent conductive film, which is used for simultaneously depositing coatings on both sides of a single glass substrate (such as figure 2 shown) or two glass substrates simultaneously deposited on one side (such as figure 1 shown).

[0044] The device includes multiple pairs of cathode groups arranged in the vacuum coating chamber, each pair of cathode groups is distributed on both sides of the substrate, and each pair of cathode groups is independently equipped with an intermediate frequency AC power supply or a bipolar pulse power supply 4; each pair of cathode groups includes two Each sputtering cathode comprises a target 1, a cathode body 2 and a magnet 3 respectively, the target is fixed on the cathode body, the cathode body is arranged on the side of the substrate, and a plurality of magnets distributed side by side are arranged in the cathode body, The two extreme faces of each magnet are vertic...

Embodiment 2

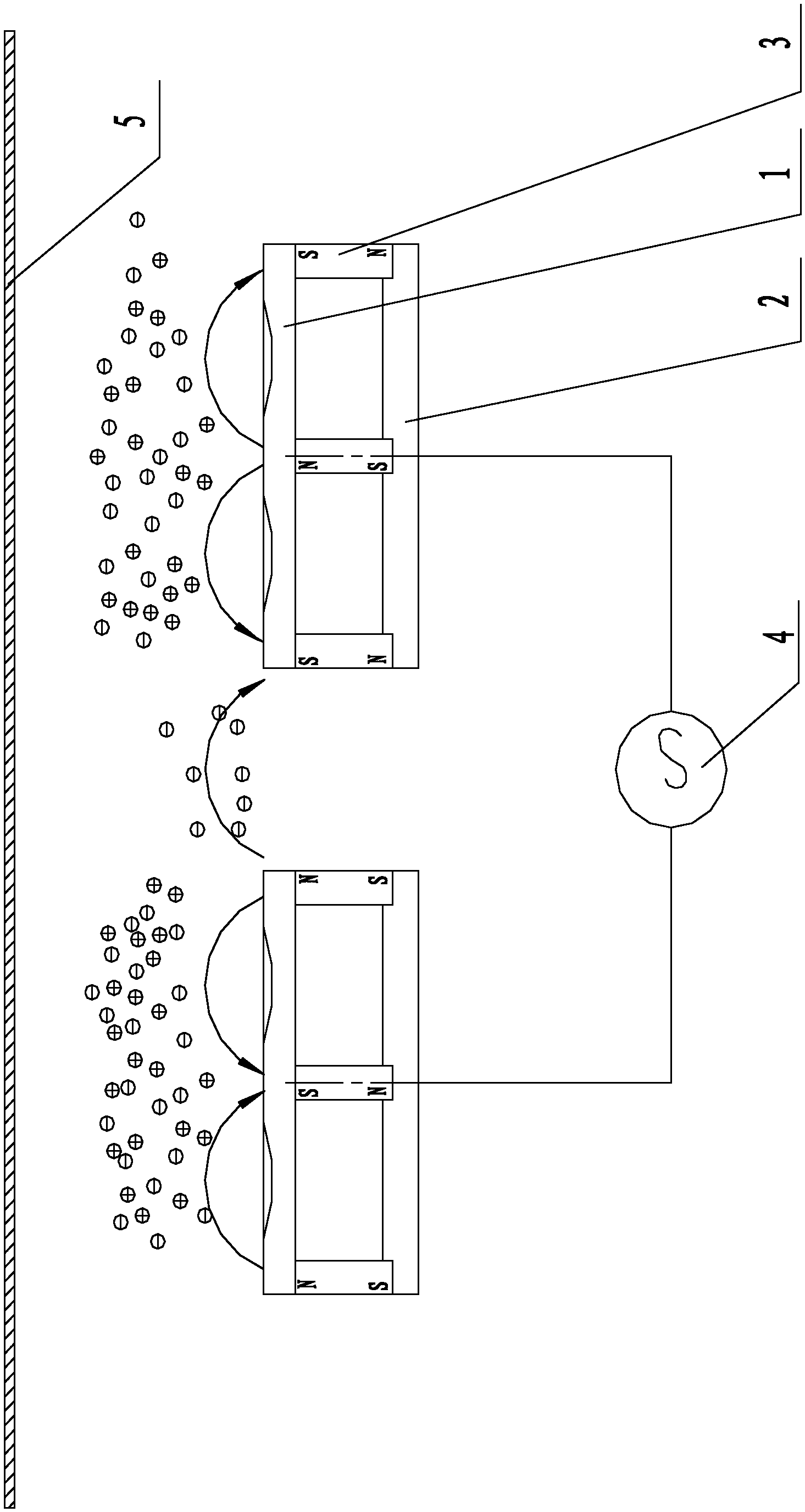

[0052] This embodiment is a low-temperature deposition device for a TCO transparent conductive film, which is used for depositing a coating film on one side of a single glass substrate.

[0053] like image 3 As shown, the device includes a pair of cathode groups arranged in the vacuum coating chamber. The cathode groups are distributed on one side of the substrate. The cathode groups are independently equipped with an intermediate frequency AC power supply or a bipolar pulse power supply 4; the cathode groups include two sputtering Cathode, each sputtering cathode comprises target material 1, cathode body 2 and magnet 3 respectively, target material is fixed on the cathode body, cathode body is arranged on the side of substrate, a plurality of magnets distributed side by side are arranged in cathode body, each magnet The two extreme faces are vertically connected with the target material and the magnetic block in the cathode body respectively; the magnetic polarity between tw...

Embodiment 3

[0058] This embodiment is a low-temperature deposition device for TCO transparent conductive film, which is used for single-sided deposition and coating of flexible coils.

[0059] like Figure 4 As shown, the device includes multiple pairs of cathode groups located in the vacuum coating chamber, each pair of cathode groups is distributed on one side of the substrate, and each pair of cathode groups is independently equipped with an intermediate frequency AC power supply or bipolar pulse power supply 4; each pair of cathode groups Include two sputtering cathodes respectively, and each sputtering cathode includes a target 1, a cathode body 2 and a magnet 3 respectively, the target is fixed on the cathode body, the cathode body is arranged on the side of the substrate, and a plurality of side-by-side distributions are arranged in the cathode body The two pole faces of each magnet are vertically connected to the target material and the magnetic block in the cathode body respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com