Bogie hearth furnace capable of automatically evening temperature

A trolley furnace, uniform temperature technology, used in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of uneven heating, high power limitation, large investment, etc., to reduce heat loss, improve thermal insulation performance, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

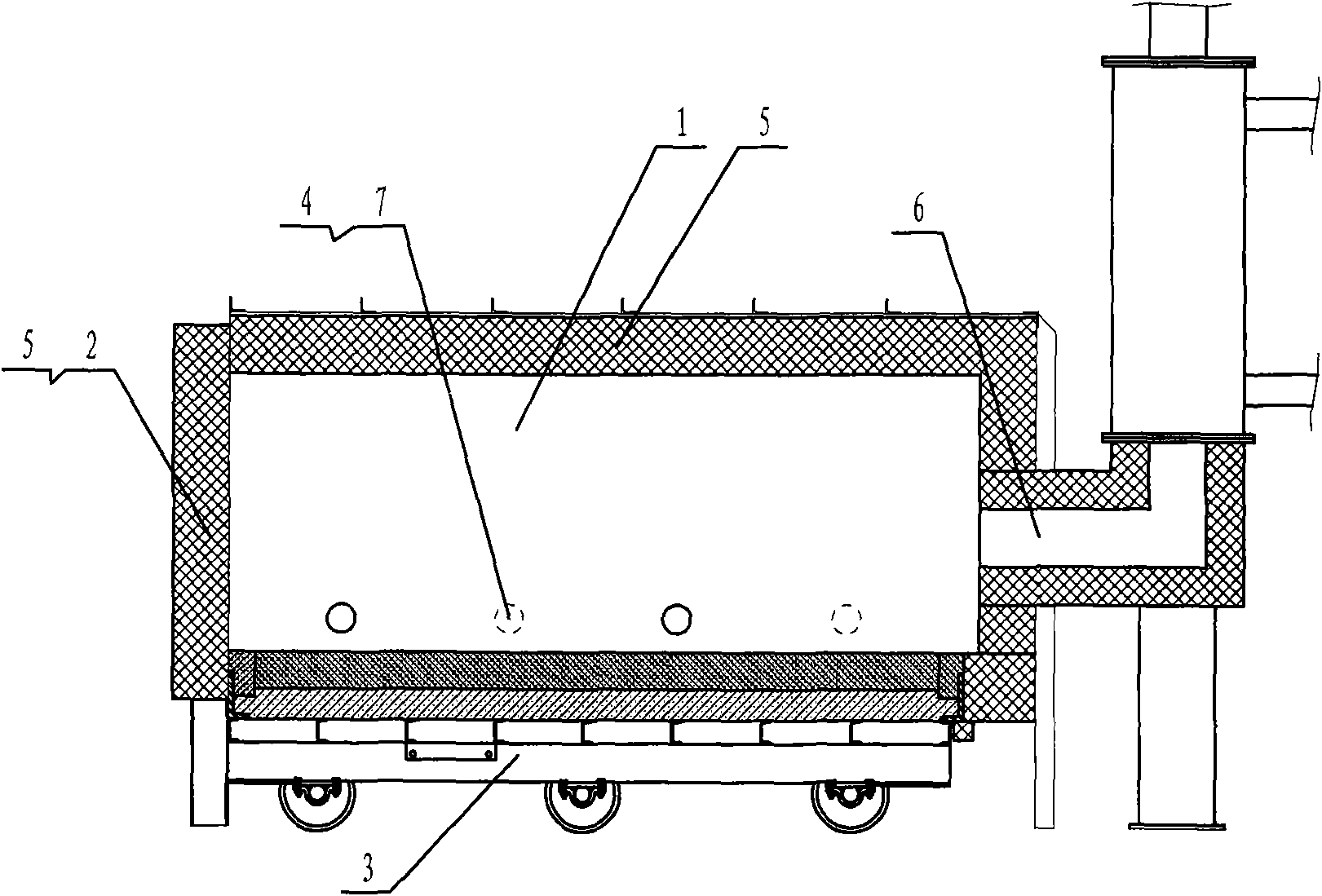

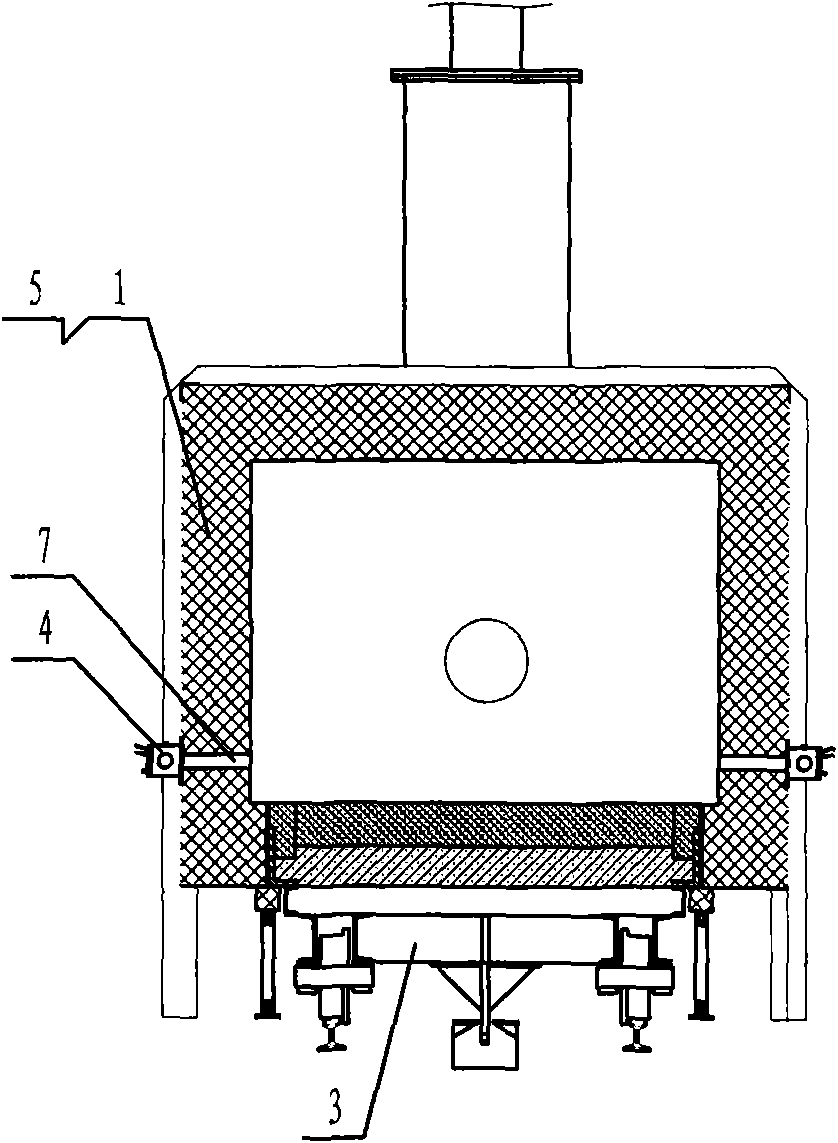

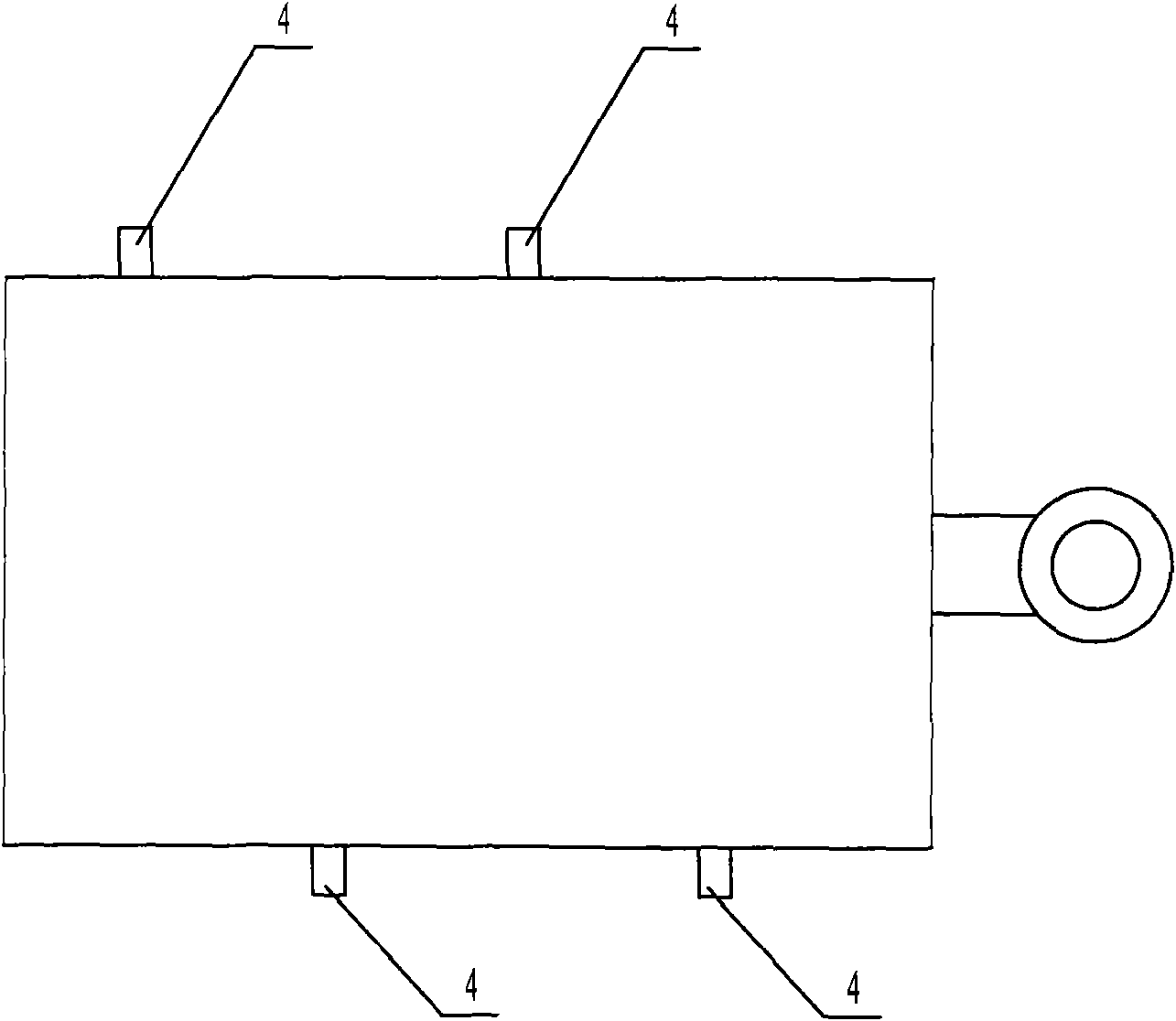

[0021] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 As shown in the figure, a trolley furnace capable of self-distributing temperature includes a furnace 1, a furnace door 2, a trolley 3, a gas burner 4 and a blower, the trolley 3 is located at the bottom of the furnace 1, and the furnace door 2 is located at the mouth of the furnace 1. The trolley 3 is closed in the furnace 1. In order to improve the thermal insulation effect of the furnace body and achieve the purpose of saving energy, high-resistance materials are used in the furnace 1 and the inner wall of the furnace door 2 and the bottom of the furnace 1 in contact with the trolley 3. The thermal fiber insulation material 5 is covered, and a flue gas exhaust duct 6 is opened at the tail of the furnace 1. The two sides of the bottom of the furnace 1 are staggered and evenly distributed with holes 7. The number of holes 7 is even. 7 are located on the same plane height, the gas burner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com