Core-shell USY@SBA-15 composite material as well as preparation method and application thereof

A composite material, core-shell technology, applied in chemical instruments and methods, hydrocarbon oil treatment, molecular sieve catalysts, etc., can solve the problem of difficulty in synthesizing core-shell USYSBA-15 composite materials, and shorten the hydrolysis time and shell layer. Controllable thickness and reduced assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

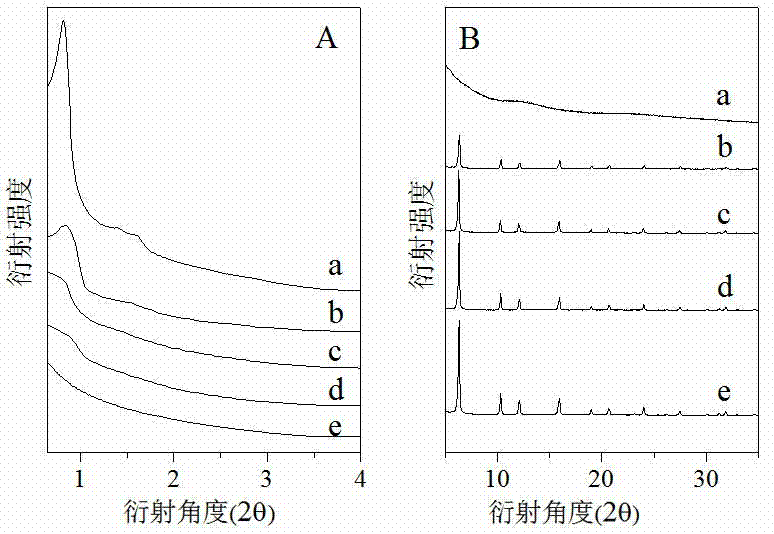

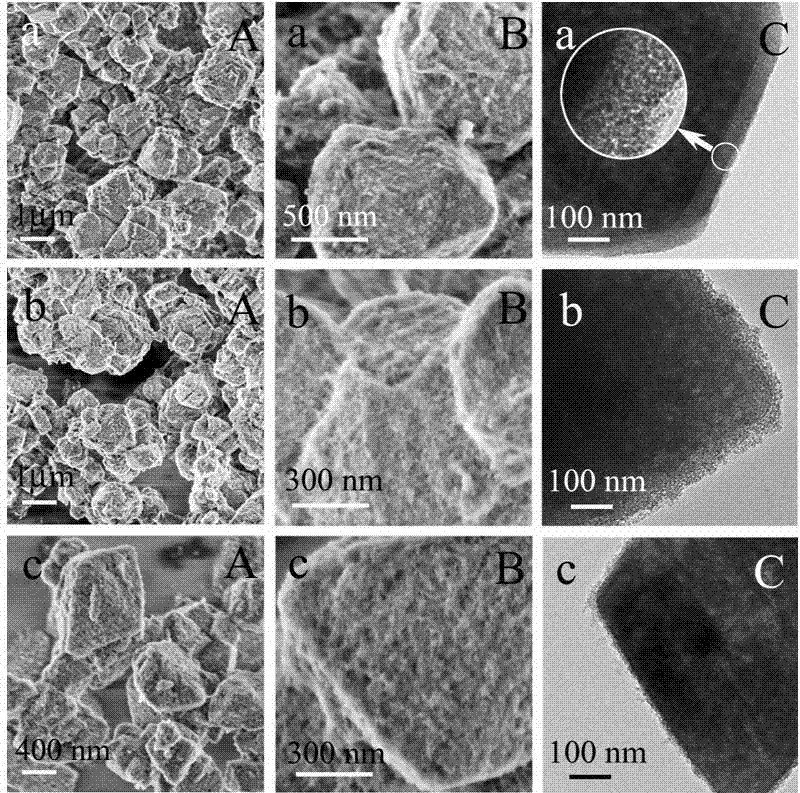

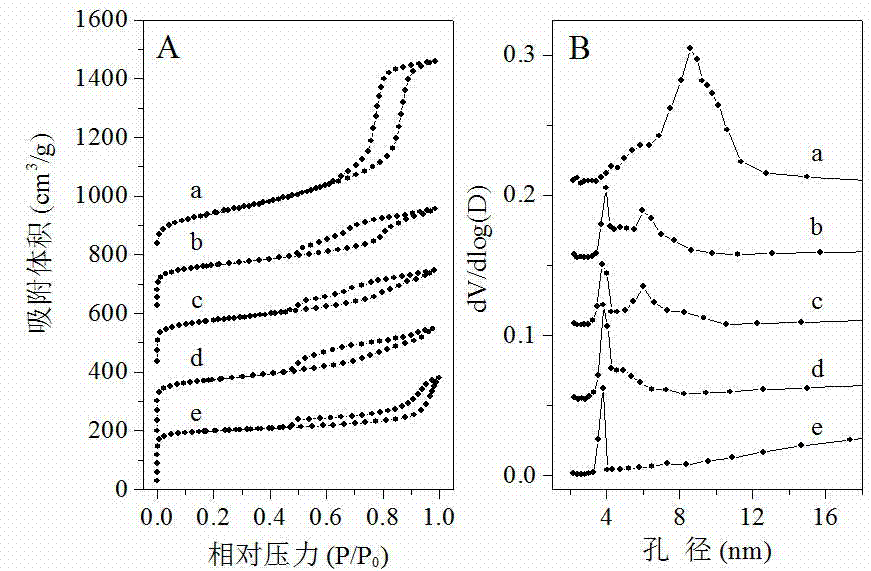

[0036] (1) With stirring, 6.0 g TEOS was added to 14.0 g HCl solution with pH=2.8. After stirring at room temperature for 6 h, the solution changed from a turbid solution to a clear solution, which was left to stand for 24 h and set aside.

[0037] (2) Dissolve 1.21 g of P123 surfactant in 130 g of 0.4 mol / L hydrochloric acid solution, add 2.38 g of USY molecular sieve after grinding, stir for 10 min, then add the TEOS pre-hydrolyzed solution prepared in advance by (1), 30 Stir at constant temperature for 4 h at ℃.

[0038] (3) Adjust the pH of the reaction solution (2) to 4.0 with ammonia water, crystallize at 100 °C for 24 h, filter, wash, dry, and roast at 550 °C for 6 h to obtain a core-shell structure USYSBA-15 with a shell thickness of 80 nm ( 80) Materials.

Embodiment 2

[0040] (1) With stirring, add 6.0 g TEOS to 14.0 g HCl solution with pH=2.8. After stirring at room temperature for 6 h, the solution turns from a turbid solution to a clear solution. Let it stand for 24 h and set aside.

[0041] (2) Dissolve 1.21 g of P123 surfactant in 130 g of 0.4 mol / L hydrochloric acid solution, add 3.55 g of ground USY molecular sieves, stir for 10 min, then add the TEOS pre-hydrolysis solution prepared in (1) in advance, 30 Stir at constant temperature for 4 h at ℃.

[0042] (3) Adjust the pH of the reaction solution (2) to 4.0 with ammonia water, crystallize at 100 °C for 24 h, filter, wash, dry, and roast at 550 °C for 6 h to obtain a core-shell structure USYSBA-15 with a shell thickness of 60 nm (60) MATERIALS.

Embodiment 3

[0044] (1) With stirring, 6.0 g TEOS was added to 14.0 g HCl solution with pH=2.8. After stirring at room temperature for 6 h, the solution changed from a turbid solution to a clear solution, which was left to stand for 24 h and set aside.

[0045] (2) Dissolve 1.21 g of P123 surfactant in 130 g of 0.4 mol / L hydrochloric acid solution, add 4.76 g of ground USY molecular sieves, stir for 10 min, then add the TEOS pre-hydrolysis solution prepared in (1) in advance, 30 Stir at constant temperature for 4 h at ℃.

[0046] (3) Adjust the pH of the reaction solution (2) to 4.0 with ammonia water, crystallize at 100 °C for 24 h, filter, wash, dry, and roast at 550 °C for 6 h to obtain a core-shell structure USYSBA-15 with a shell thickness of 30 nm (30) MATERIALS.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com