Grinding device and garbage compactor with grinding device

A garbage compressor and crushing device technology, which is applied in the direction of grain processing, etc., can solve the problems of poor dehydration effect of garbage, high garbage water content, heavy garbage weight, etc., to avoid sewage dripping, improve transportation efficiency, and good treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

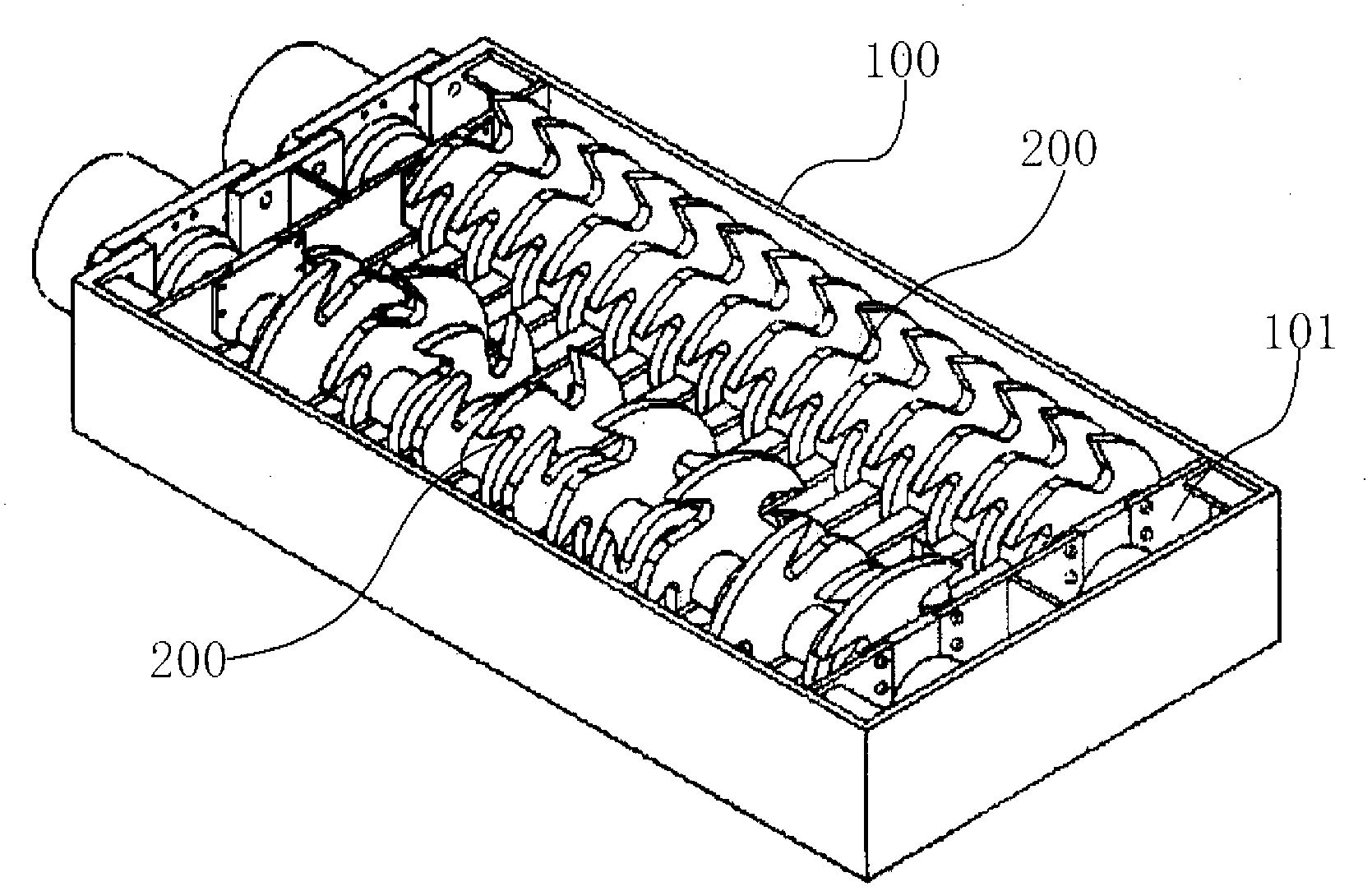

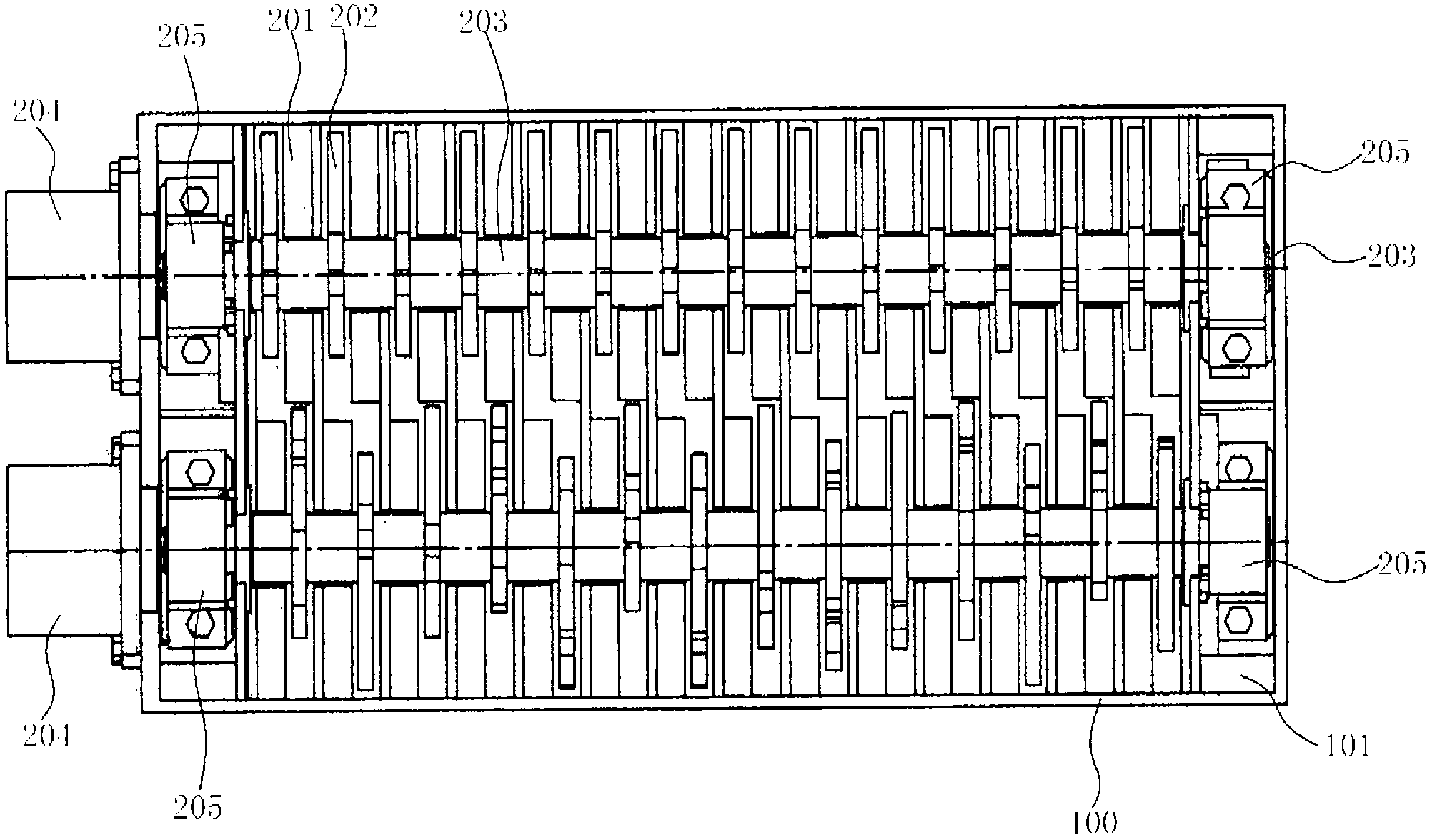

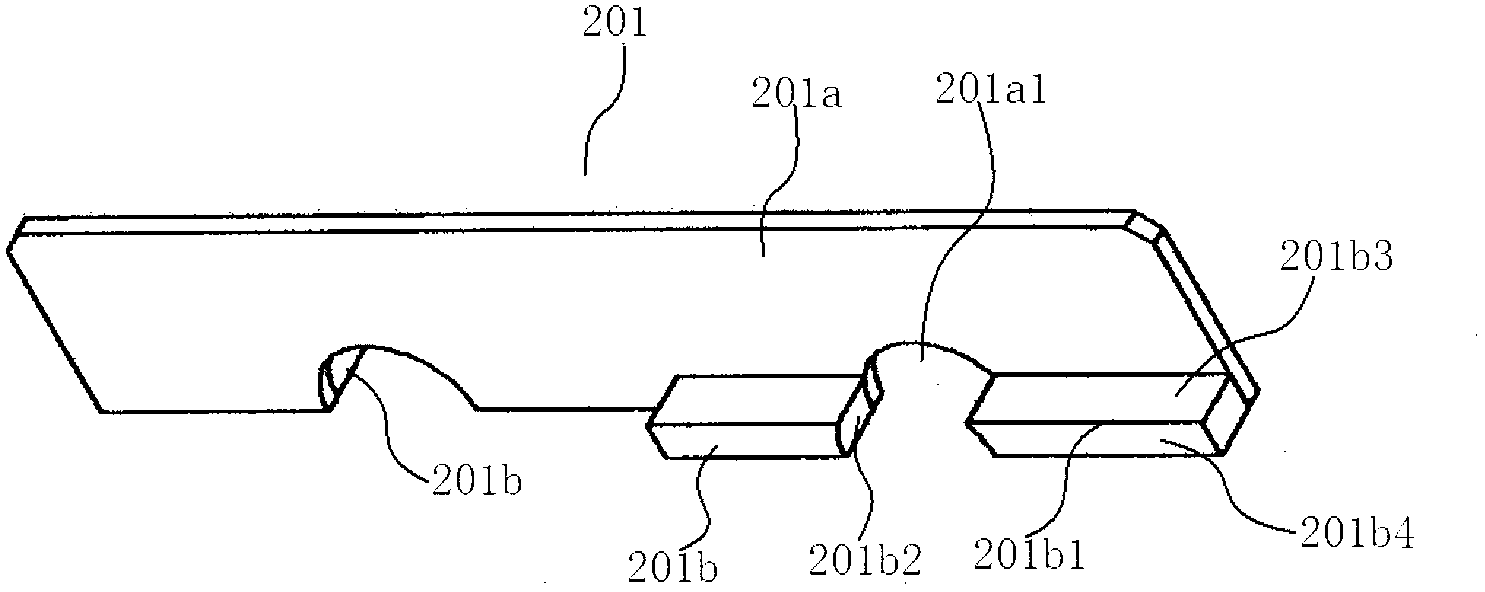

[0033] see figure 1 with figure 2 , in order to be able to shear and crush the garbage, the crushing device provided by the present invention mainly includes a frame 100 and a crushing knife set 200 arranged in the frame, and the moving knife in the crushing knife set rotates around the axial direction under the action of the driving force Cooperate with the fixed knife to form a shear force on the garbage, so as to realize the crushing of the garbage.

[0034] Wherein, the frame 100 is the frame of the whole pulverizing device, which is specifically a metal rectangular frame with a certain height, with placement grooves 101 arranged at both ends, and the middle area 102 is the pulverizing working area of the pulverizing knife set 200 . The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com