High-resistance steam resistant packaging film convenient for direct microwave heating and preparation method thereof

A microwave heating and cooking-resistant technology is applied in the field of packaging materials, which can solve the problems that the barrier performance is greatly affected by the environment, the barrier material is difficult to adapt to, and the aluminized film is not easy to recycle, etc., and achieves high food hygiene safety and quality stability. Good adaptability, comprehensive and thorough sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

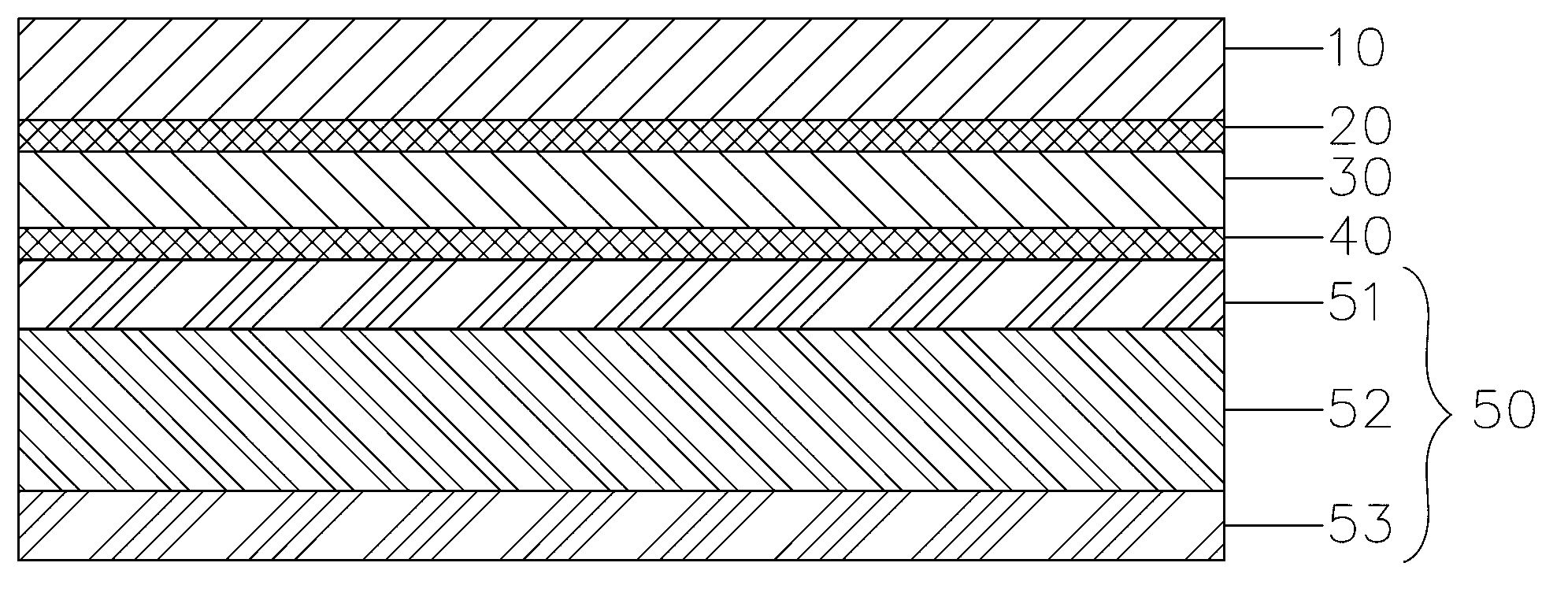

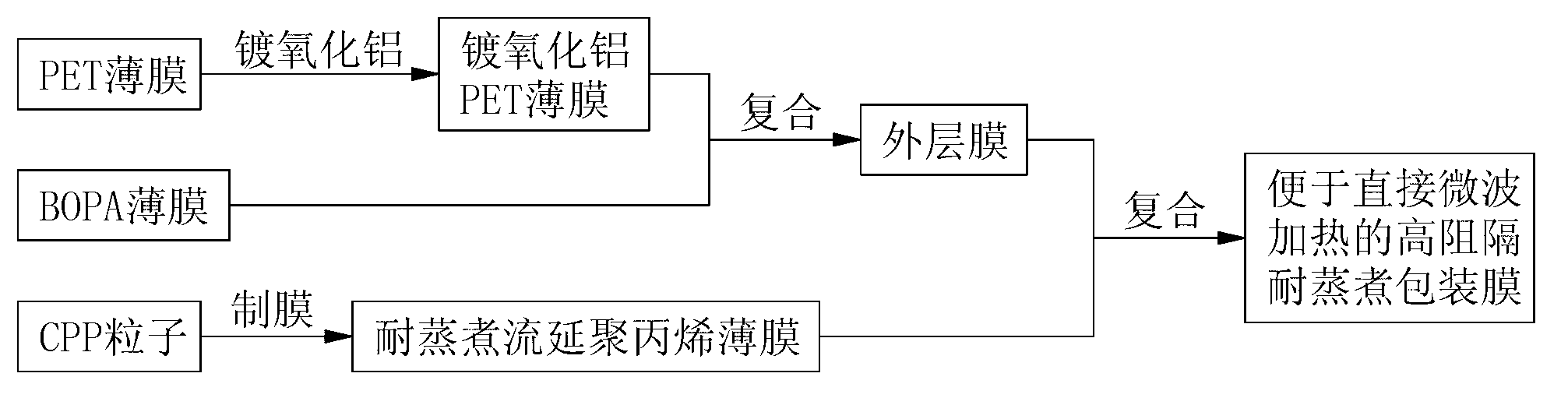

[0054] Such as figure 2 Shown, a kind of preparation method of the high barrier retort resistant packaging film that is convenient to direct microwave heating, it comprises the steps:

[0055] 1) Alumina-coated PET film is obtained by subjecting the PET film to an alumina-plating process;

[0056] And the ingredients of retort-resistant cast polypropylene film RCPP are prepared through extrusion process, cooling and shaping process, thickness measurement process, deflection process, corona process, and edge trimming process to obtain retort-resistant cast polypropylene film RCPP. The retort-resistant cast polypropylene film RCPP is composed of a corona layer 51, an intermediate layer 52 and a heat-sealing layer 53 connected in sequence;

[0057] 2) Then, the outer layer film is obtained by laminating the alumina-coated PET film and the BOPA layer of the polyamide film through the first retort-resistant adhesive layer;

[0058] 3) The polyamide film BOPA layer of the outer f...

Embodiment 1

[0062] 1) Preparation of alumina-coated PET film

[0063] Alumina-coated PET film is produced by subjecting PET film to aluminum oxide evaporation process

[0064] Alumina evaporation technology is based on the traditional aluminum plating process, using a radio frequency plasma treatment system to clean and functionalize the surface of the evaporation substrate, that is, PET film, and then using a microwave plasma treatment system to ionize oxygen and aluminum vapor to form oxygen ions and aluminum ions; the ionized oxygen ions and aluminum ions fully react in the upper part of the evaporation zone to form aluminum oxide uniformly deposited on the surface of the PET film, thus forming a dense transparent ALOx evaporation layer.

[0065] Preparation of RCPP film

[0066] The preparation of RCPP film includes the following processes in sequence: extrusion process, cooling and shaping process, thickness measurement process, deflection process, corona process, trimming and windi...

Embodiment 2

[0082] 1) Preparation of alumina-coated PET film

[0083] Alumina-coated PET film is produced by subjecting PET film to aluminum oxide evaporation process

[0084]Alumina evaporation technology is based on the traditional aluminum plating process, using a radio frequency plasma treatment system to clean and functionalize the surface of the evaporation substrate, that is, PET film, and then using a microwave plasma treatment system to ionize oxygen and aluminum vapor to form oxygen ions and aluminum ions; the ionized oxygen ions and aluminum ions fully react in the upper part of the evaporation zone to form aluminum oxide uniformly deposited on the surface of the PET film, thus forming a dense transparent ALOx evaporation layer.

[0085] Preparation of RCPP film

[0086] The preparation of RCPP film includes the following processes in sequence: extrusion process, cooling and shaping process, thickness measurement process, deflection process, corona process, trimming and windin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com