Zirconium oxide tundish pure zirconium water gap and manufacturing process thereof

A manufacturing process and technology of zirconia, which is applied in the field of zirconia tundish pure zirconium nozzle and its manufacturing process, can solve the problems of unsatisfactory use requirements, short service life, etc., and achieve the effect of enhancing stability and improving the scouring performance of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

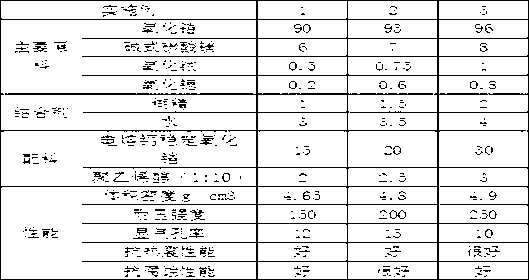

[0033] Table 1 lists the composition (mass parts) and performance of the pure zirconium nozzle of the zirconia tundish of the present invention

[0034] The composition (mass parts) and characteristic of table 1 embodiment of the present invention

[0035]

[0036] It can be seen from the table that the present invention has the advantages of high pressure resistance, thermal shock resistance and erosion resistance. Under the condition of using high-alloy steel, the pure zirconium nozzle brick in the zirconia tundish of the present invention can pass through more than 700 tons of molten steel.

[0037] figure 1 It is a schematic diagram of Example 1 of the present invention. The center of the semi-finished product 1 after cutting is a hollow cylinder 3. When the temperature of the iron shell suit 2 is between 700°C and 800°C, the iron shell suit 2 is shrunk and cooled by air naturally. Fastened on the cutting semi-finished product 1, wherein the iron shell suit 2 is made ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com