Cleaning agent for electronics and preparation method thereof

A cleaning agent, electronic technology, applied in the direction of organic non-surface active cleaning composition, etc., can solve the problems of unenvironmental protection, unsatisfactory cleaning effect, uneven quality and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] In parts by weight, including: 20 parts of ethanol, 70 parts of hexamethyldisiloxane, and 10 parts of acetone;

[0011] Preparation method: Mix 20 parts of ethanol, 70 parts of hexamethyldisiloxane, and 10 parts of acetone evenly, then add it to a stirring reaction kettle, and stir at 65 °C and 60 R / MIN for 30 minutes. Pressure distillation, collecting components at 50-60°C to obtain cleaning agent.

[0012] 1. Cleaning effect experiment:

[0013] 1. Test equipment: 1 electrostatic brush, 9 computer motherboards, 3 cleaning bottles, and 1 cardboard.

[0014] 2. Test samples: imported solvent cleaners on the market, domestic solvent cleaners on the market, solvent cleaners in Example 1, high rosin flux, low rosin flux, and non-rosin flux.

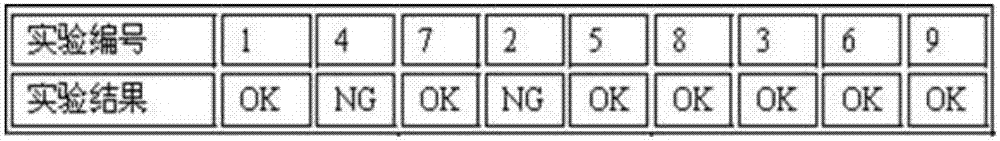

[0015] 3. Test method: Spray three computer motherboards with high rosin flux, low rosin flux and non-rosin flux in turn, and pass through the tin furnace, respectively numbered 1, 2, 3; 4, 5, 6; 7 , 8, 9;

[0016] Spray three com...

Embodiment 2

[0031] In parts by weight, it includes: 10 parts of ethanol, 10 parts of isopropanol, 50 parts of hexamethyldisiloxane, 20 parts of octamethylcyclotetrasiloxane, 5 parts of acetone, and 5 parts of cyclohexanone;

[0032] Preparation method: Mix 10 parts of ethanol, 10 parts of isopropanol, 50 parts of hexamethyldisiloxane, 20 parts of octamethylcyclotetrasiloxane, 5 parts of acetone and 5 parts of cyclohexanone, and then add to the There is a stirred reactor, and the temperature is 65°C and 60R / MIN stirring reaction for 30 minutes, and the components at 50-60°C are collected through vacuum distillation to obtain a cleaning agent.

[0033] 1. Cleaning effect experiment:

[0034] 1. Test equipment: 1 electrostatic brush, 9 computer motherboards, 3 cleaning bottles, and 1 cardboard.

[0035] 2. Test samples: imported solvent cleaners on the market, domestic solvent cleaners on the market, solvent cleaners in Example 2, high rosin flux, low rosin flux, and non-rosin flux.

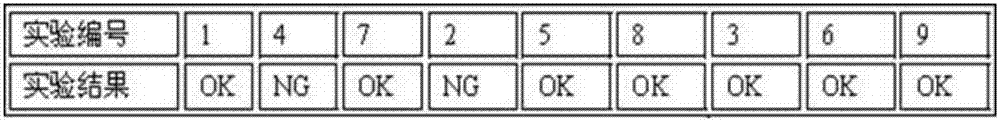

[003...

Embodiment 3

[0053] In parts by weight, including: 20 parts of methanol, 40 parts of hexamethylcyclotrisiloxane, 40 parts of acetone;

[0054] Preparation method: Mix 20 parts of methanol, 40 parts of hexamethylcyclotrisiloxane, and 40 parts of acetone evenly, then add to a stirring reaction kettle, stir and react at 65 °C and 60 R / MIN for 30 minutes, and then reduce Pressure distillation, collecting components at 50-60°C to obtain cleaning agent.

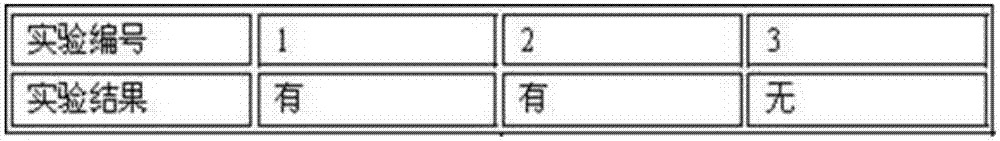

[0055] 1. Cleaning effect experiment:

[0056] 1. Test equipment: 1 electrostatic brush, 9 computer motherboards, 3 cleaning bottles, and 1 cardboard.

[0057] 2. Test samples: imported solvent cleaners on the market, domestic solvent cleaners on the market, solvent cleaners in Example 3, high rosin flux, low rosin flux, and non-rosin flux.

[0058] 3. Test method: Spray three computer motherboards with high rosin flux, low rosin flux and non-rosin flux in turn, and pass through the tin furnace, respectively numbered 1, 2, 3; 4, 5, 6; 7 , 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com