Plasma surface treating device for anti-abrasion tamping pick for railway and using method thereof

A surface treatment device, plasma technology, applied in the direction of roads, tracks, coatings, etc., can solve the problems of complex process and difficult performance guarantee, and achieve the effect of deep thickness, low processing cost and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

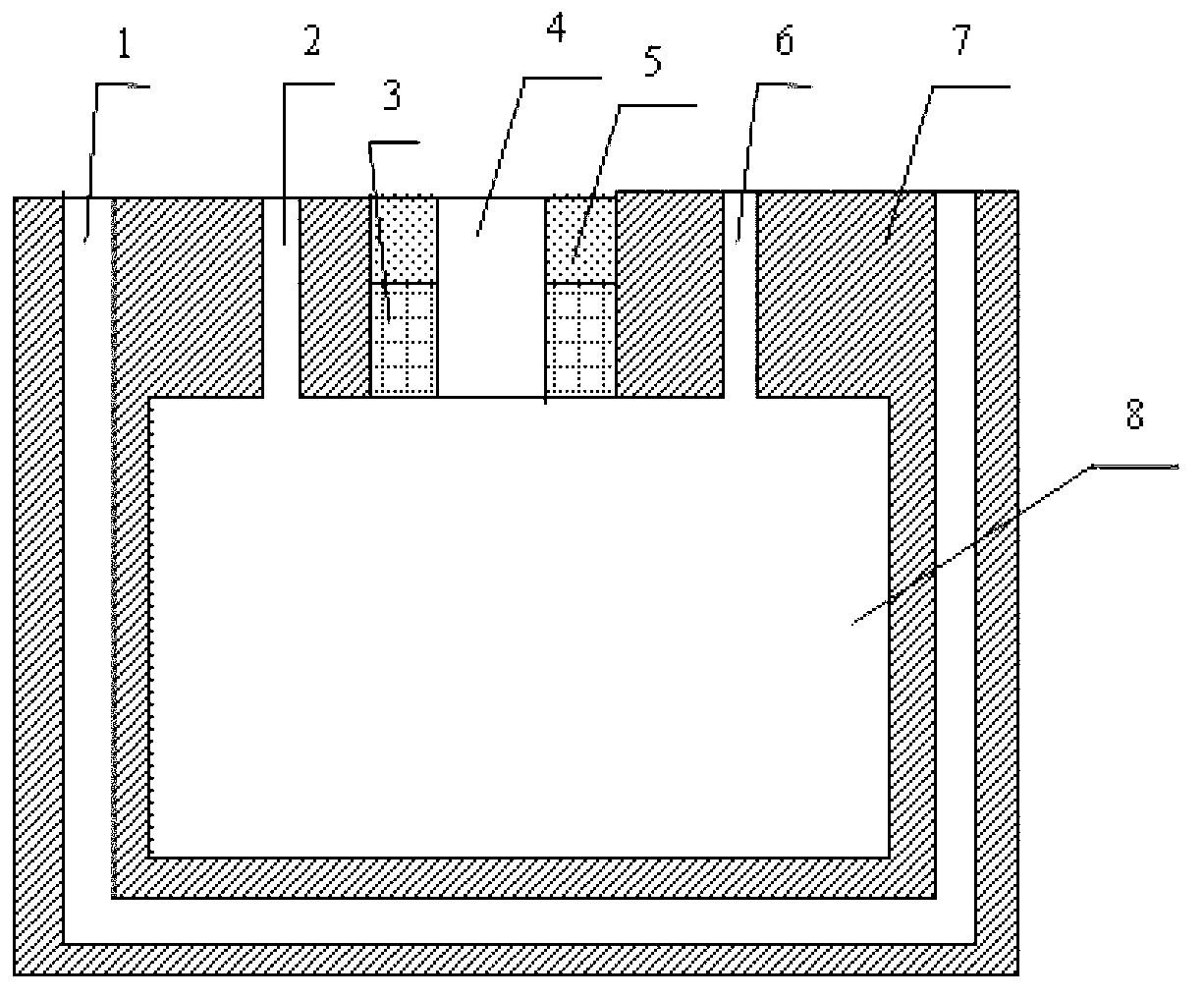

[0018] Specific implementation mode one: combine figure 1 Illustrate this specific embodiment, a kind of railway wear-resisting pounding pick plasma surface treatment device of this embodiment is made of cooling water channel 1, argon and nitrogen gas mixture channel 2, high temperature resistant ceramic element 3, pounding pick It consists of opening 4, high temperature resistant seal 5, vacuum pump exhaust channel 6, detachable stainless steel plasma generator entity 7 and reaction chamber 8. Entity 7 extends from the inside to the outside, the high temperature resistant ceramic element 3 and the high temperature resistant seal 5 are arranged on the reserved opening 4 of the hammer head, the high temperature resistant seal 5 is above the high temperature resistant ceramic element 3, and the cooling water passage 1 is opened inside the detachable stainless steel plasma generator entity 7, and the argon and nitrogen mixed gas channel 2 and the vacuum pump exhaust channel 6 are...

specific Embodiment approach 2

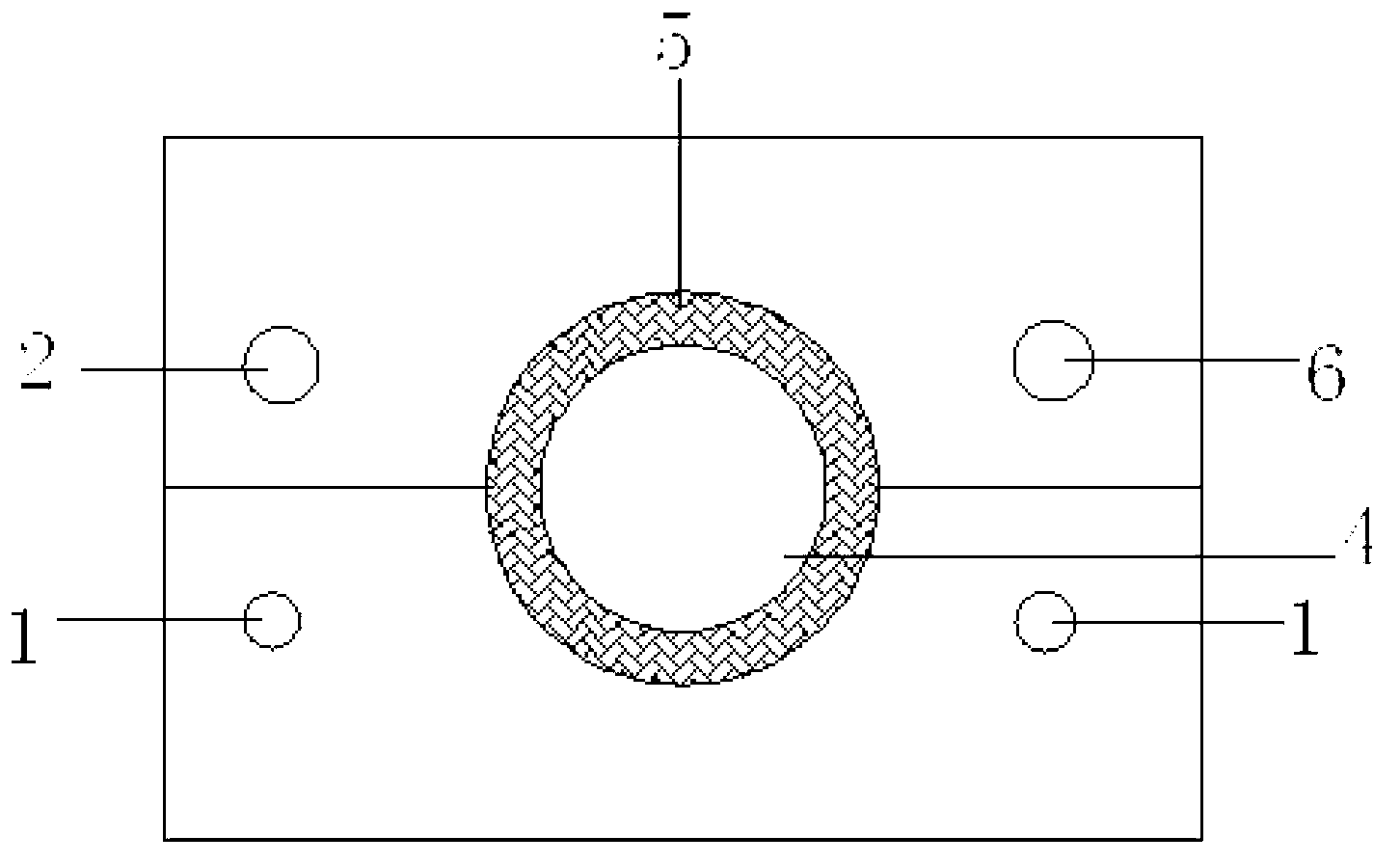

[0020] Specific implementation mode two: combination figure 2 This specific embodiment is described. The difference between this embodiment and specific embodiment 1 is that the wear-resistant tamp pick plasma surface treatment device for railway uses stainless steel screws to disassemble the upper mold and the lower mold. Others are the same as in the first embodiment.

specific Embodiment approach 3

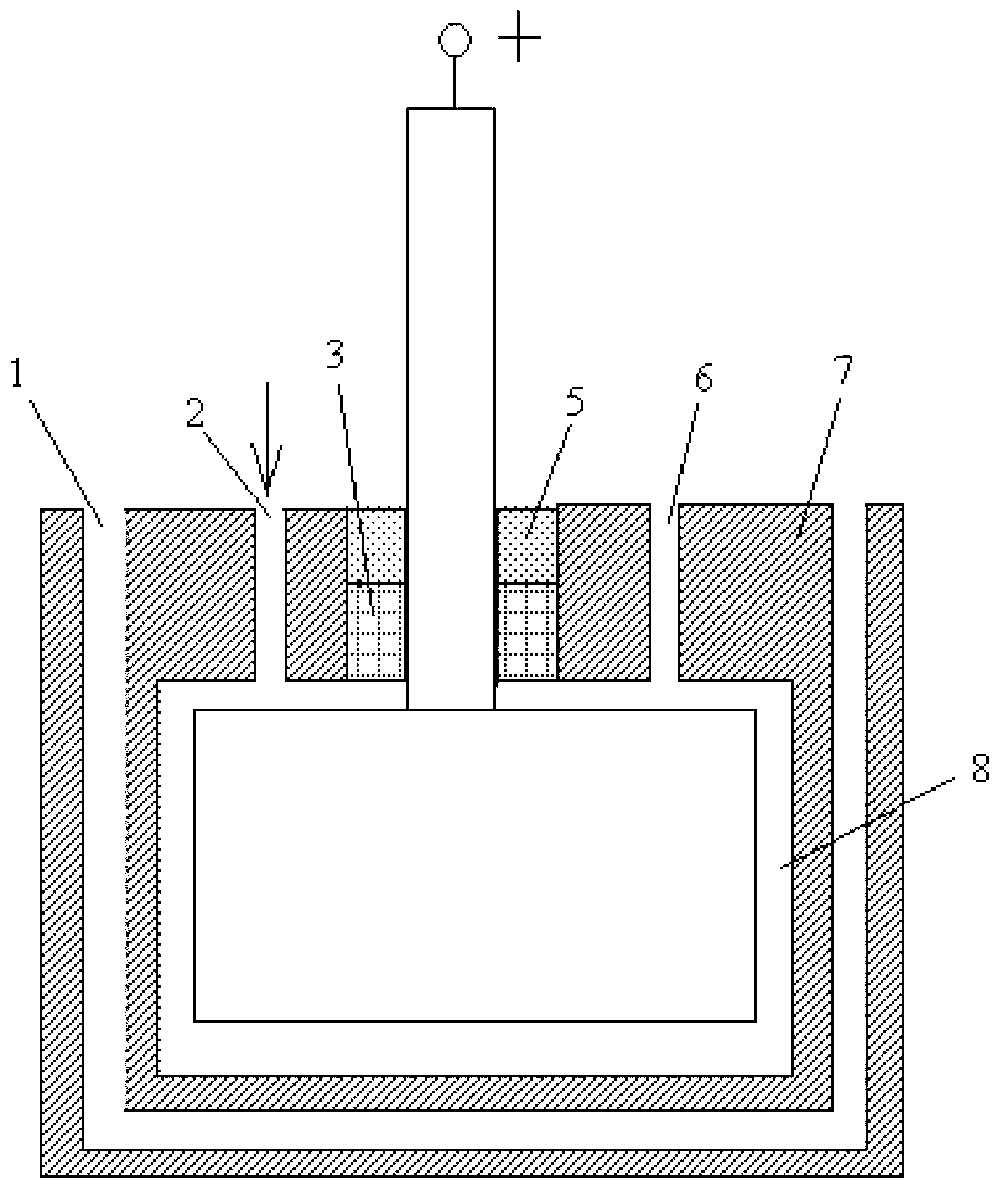

[0021] Specific implementation mode three: combination image 3 Describe this specific implementation mode. This embodiment mode provides a method for using a wear-resistant tamping pick plasma surface treatment device for railways, which is specifically completed according to the following steps:

[0022] 1. Disassemble the plasma surface treatment device, put the tamper into the reaction chamber 8, and then install the plasma surface treatment device. The tamper head is connected to the positive electrode through the reserved port 4 of the tamper head, and the high temperature resistant ceramic The element 3 and the high temperature resistant seal 5 seal the reaction chamber 8, open the cooling water circulation in the cooling water passage 1, and connect the vacuum pump to the vacuum pump exhaust passage 6 to evacuate the air pressure to 10 -3 ~10 -2 Pa;

[0023] 2. Fill the reaction chamber with the mixed gas of argon and nitrogen through the channel 2 of the mixed gas o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com