A kind of manufacture method of superfine fiber synthetic leather

A manufacturing method and superfine fiber technology, applied in the field of synthetic leather, can solve the problems of unsightly appearance, no surface texture, and unenvironmental protection, and achieve the effects of strong toughness, excellent elastic recovery and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

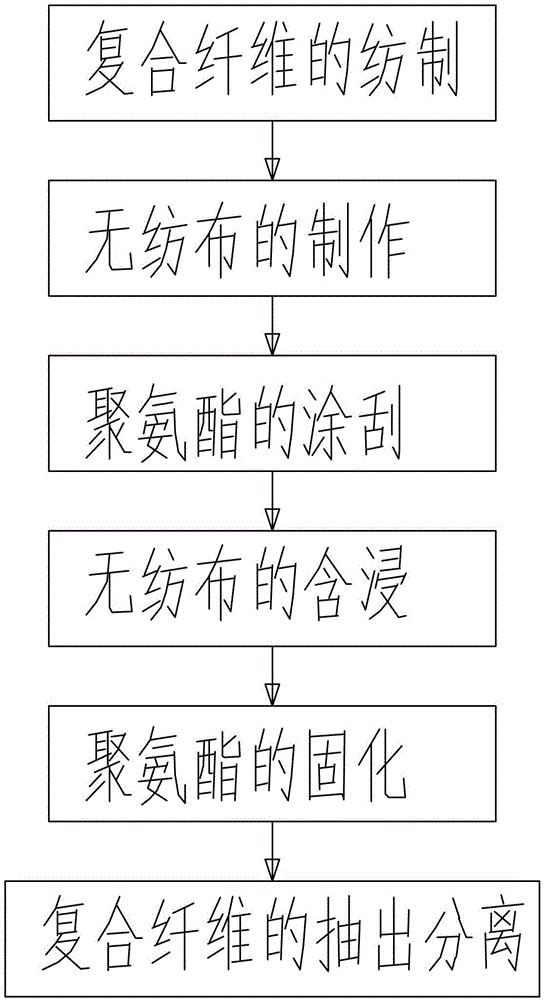

Image

Examples

Embodiment Construction

[0017] The implementation of the present invention will be described in detail below in conjunction with specific examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention.

[0018] Unless otherwise specified, the technical means used in the examples are conventional means well known to those skilled in the art, and the reagents and products used are also commercially available. Various processes and methods not described in detail are conventional methods well known in the art, and the sources, trade names and necessary listing of components of the reagents used are indicated when they first appear.

[0019] Embodiments of the invention are:

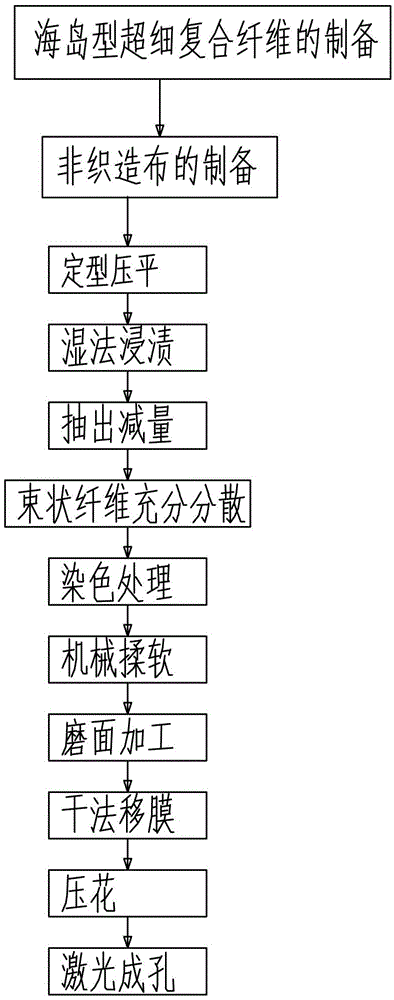

[0020] refer to figure 2 , a kind of manufacture method of microfiber synthetic leather, comprises the following steps:

[0021] (1) Preparation of sea-island ultrafine composite fibers: mix polybutylene terephthalat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com