Self-heat-dissipation light emitting diode (LED) light source and manufacturing method

An LED light source and self-heating technology, applied in the field of self-heating LED light source and manufacturing, can solve the problems of increased cost of raw materials, high cost, poor bonding between metal and plastic, etc., and achieve the effects of simple structure, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

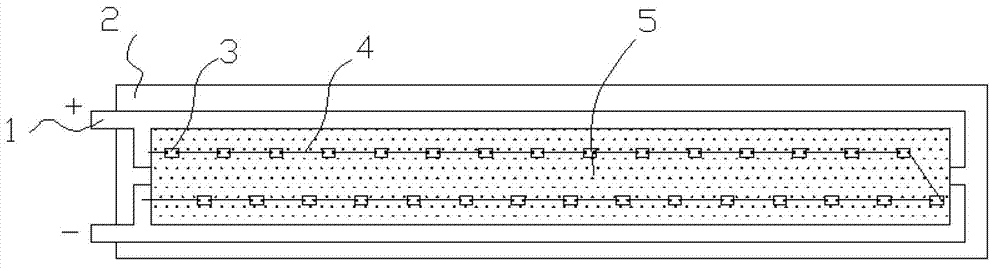

[0031] Such as figure 1 As shown, the plane rectangular self-radiating LED light source includes a heat-dissipating substrate 2, positive and negative electrical leads 1, LED light-emitting chipset and silica gel phosphor mixture 5, the heat-dissipating substrate 2 is rectangular, and each LED in the LED light-emitting chipset emits light The chips 3 are electrically connected, the positive and negative electrical leads 1 are bonded on the heat dissipation substrate 2 through silica gel, the LED light-emitting chips 3 are fixed on the heat dissipation substrate 2 through silica gel, and the two ends of the LED light-emitting chipset are respectively connected Positive and negative electrical leads 1, and the silica gel fluorescent powder mixture 5 encapsulates the LED light-emitting chipset.

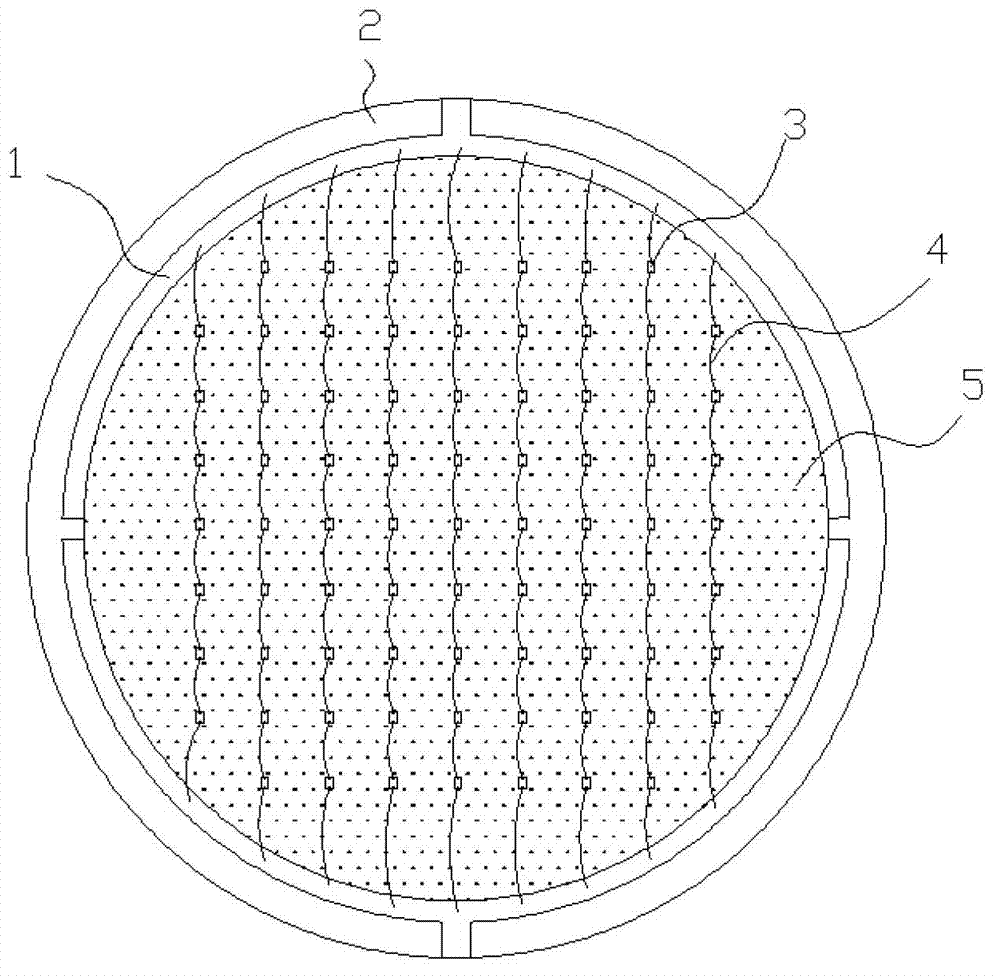

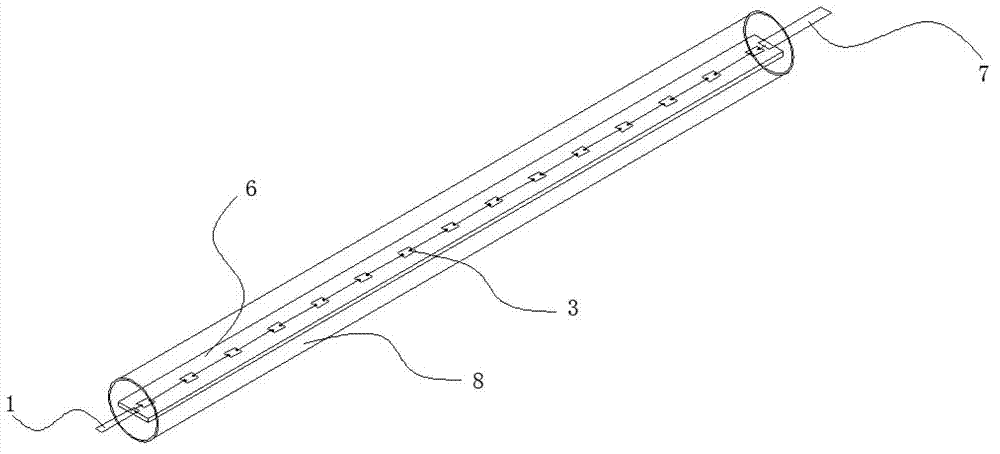

[0032] Such as figure 2 As shown, the flat c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com