Soldering flux for aluminum and steel dissimilar metal alternating-current arc melt brazing

A technology of dissimilar metals and AC arcs, applied in metal processing equipment, welding media, welding equipment, etc., can solve problems such as unsatisfactory joint formation and performance, increased interface brittleness, and difficulty in maintaining arcs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

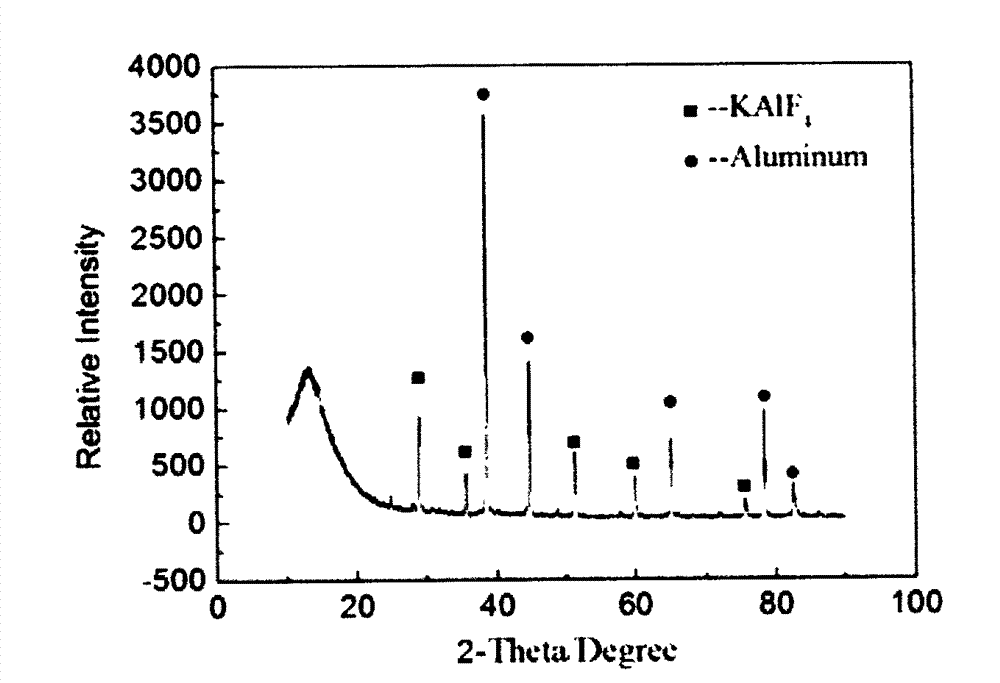

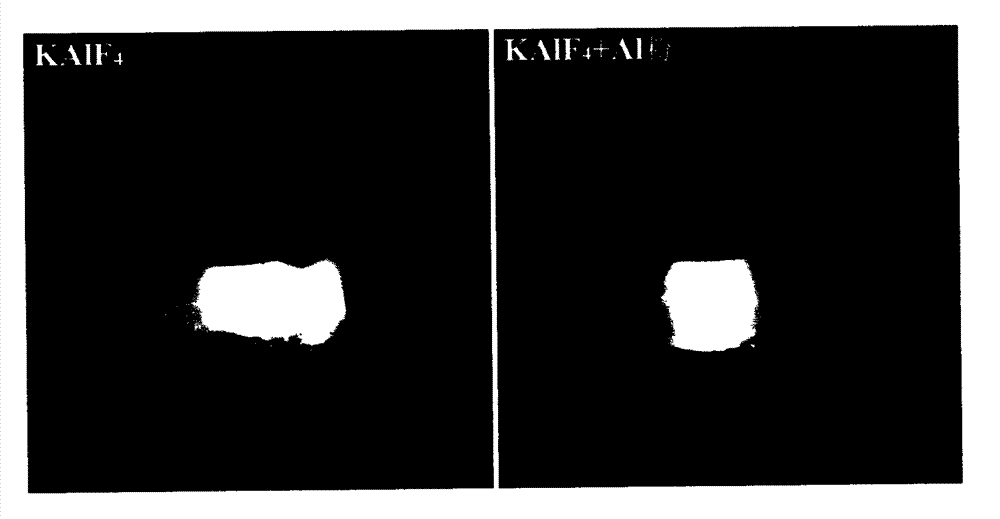

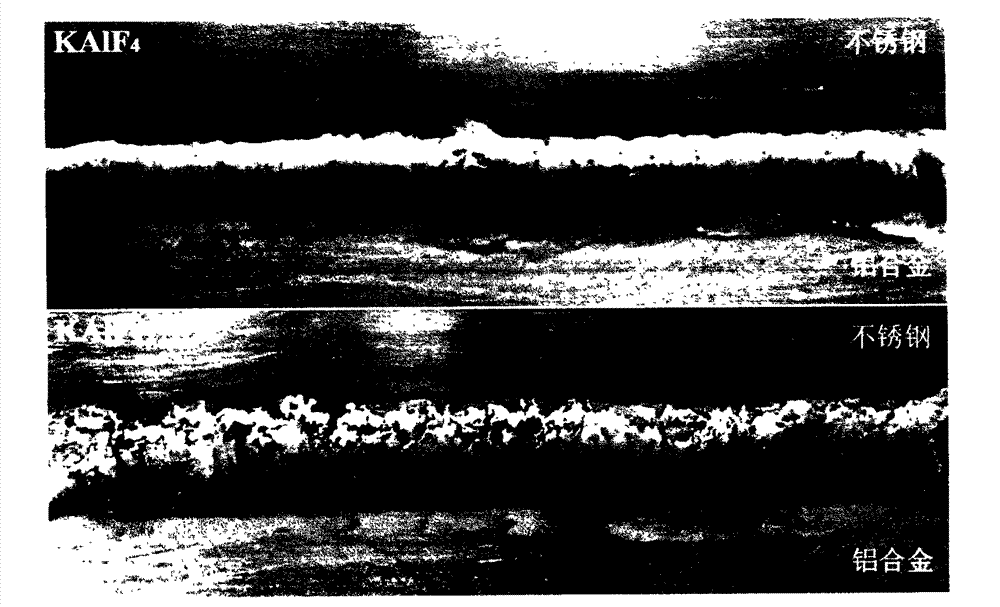

[0018] combine figure 1 , a method for making flux for aluminum and steel dissimilar metals by AC arc fusion brazing, firstly KAlF 4 Powder and aluminum powder are mixed according to the mass ratio of 7:3, then mixed with acetone to form a uniform suspension solution, and then KAlF 4 0.5% potassium sodium tartrate of the total mass of the powder and the aluminum powder can be dissolved in distilled water, and finally mixed into the above suspension solution and stirred evenly to make a brazing flux. The aluminum powder has a purity of 99.99%. Then use a fine brush to evenly coat the prepared flux on the clean steel surface. The thickness of the flux is preferably about 0.3mm. With the help of a small amount of binder potassium sodium tartrate, the flux can be evenly and firmly coated on the steel surface. The XRD analysis of the morphology of the stainless steel surface after brushing the flux and the composition of the flux is as follows: figure 1 shown.

Embodiment 2

[0020] A method for preparing flux for aluminum and steel dissimilar metals by alternating current arc melting and brazing, first KAlF 4 Powder and aluminum powder are mixed according to the mass ratio of 4:6, then mixed with acetone to form a uniform suspension solution, and then KAlF 4 0.5% potassium sodium tartrate of the total mass of the powder and the aluminum powder can be dissolved in distilled water, and finally mixed into the above suspension solution and stirred evenly to make a brazing flux.

Embodiment 3

[0022] A method for preparing flux for aluminum and steel dissimilar metals by AC arc melting and brazing. First, Nocolok and aluminum powder are mixed in a mass ratio of 5:5, then mixed with acetone to form a uniform suspension solution, and then Nocolok and 0.5% potassium sodium tartrate of the total mass of the aluminum powder can be dissolved in distilled water, and finally mixed into the above suspension solution and stirred evenly to make brazing flux.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com