Grinding chatter prediction method based on maximum information entropy and directional divergence

A technology of maximum information entropy and directional divergence, which is applied in the field of parts grinding and processing, can solve the problems that the model cannot be established and the analysis process cannot be self-adaptive, and achieves fast calculation speed, strong anti-interference ability, and high recognition rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment one (theoretical basis)

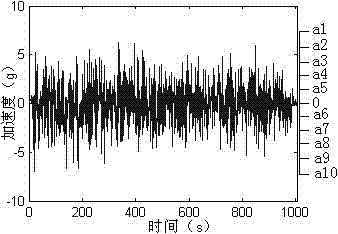

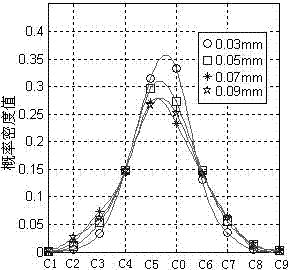

[0027] The present invention takes the acceleration vibration signal of the workbench during the surface grinding process as the research object, and uses an unsupervised data processing method, that is, a chatter prediction method based on maximum information entropy and direction divergence, to analyze the grinding chatter state Make predictions. The present invention first uses the principle of maximum information entropy in information theory to accurately estimate the probability density distribution of the vibration signal of the workbench, and then uses the direction divergence to quantify the maximum entropy probability density distribution, and the surface grinding process is controlled by the change of the direction divergence value. The state is observed, and then the purpose of surface grinding chatter prediction is achieved.

[0028] Two aspects that the present invention needs to consider:

[0029] 1. Construction of ...

Embodiment 2

[0076] Embodiment two (specific example)

[0077] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0078] Step 1, the construction of the vibration signal acquisition system in the grinding process.

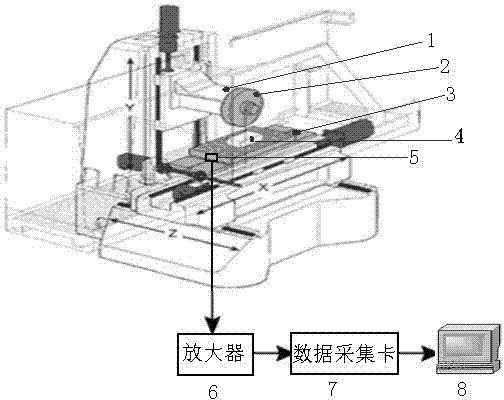

[0079] According to the characteristics of the vibration signal during the grinding process, the vibration signal measurement system is mainly composed of the following components: three-way acceleration sensor 5 (sensitivity: 100mV / g; frequency range: 0.3~10KHz; peak value ±50g), amplifier 6, and data acquisition card 7 (distributed system structure, dual DSP parallel processing technology, low-noise hardware design technology, filtering technology and 24-bit resolution ADC / DAC, sampling frequency can reach 192kHz,), computer 8.

[0080] Step 2, selecting the vibration acceleration signal of the workbench for analysis to determine the location of the sensor.

[0081] figure 1 It is a surface grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com