A method for removing iron in the process of extracting aluminum from coal gangue

A technology for removing iron from coal gangue and magnetic separation, applied in chemical instruments and methods, iron halide, magnetic separation, etc. The effect of reducing the content and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

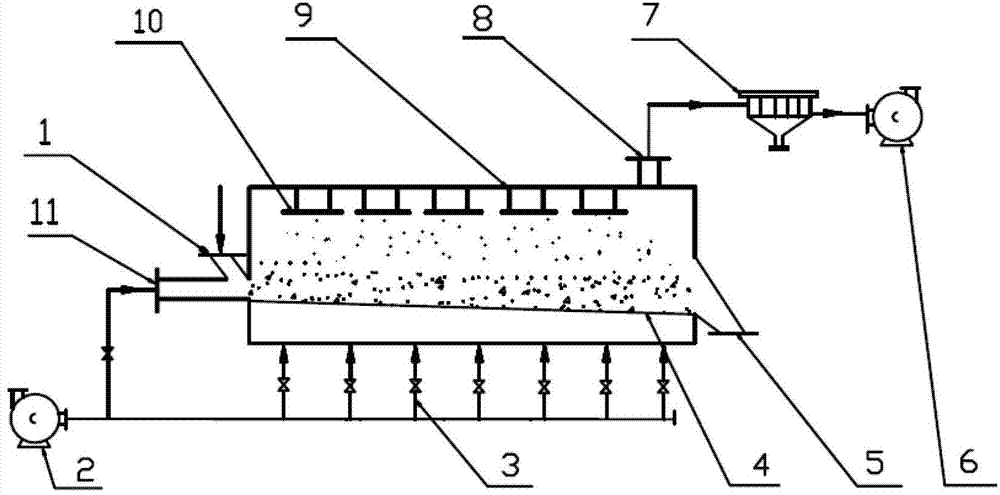

[0018] A horizontal fluidized magnetic separation device, such as figure 1 Shown: including magnetic separation bin 9, feed inlet 1, blower 2, air branch pipe 3, gas distribution plate 4, discharge outlet 5, exhaust outlet 8, dust collector 7, induced draft fan 6, electromagnet 10, blowing pipe 11; the inner bottom of the magnetic separation chamber 9 is provided with a gas distribution plate 4 at 10° to the horizontal direction, and the feed inlet 1 is on the side wall of the magnetic separation chamber 9 on the higher side of the gas distribution plate 4, and is connected with the horizontal blowing pipe 11 Connected, the discharge port 5 is located on the other side wall of the magnetic separation bin 9, and the position of the discharge port 5 is consistent with the height of the lower side of the gas distribution plate 4 to ensure smooth discharge; the magnetic separation bin 9 Five electromagnets 10 are arranged on the inner top, and a row of air branch pipes 3 are arran...

Embodiment 2

[0021] The coal gangue with an alumina content of 25.9%, an iron oxide content of 2.4%, and a carbon content of 21% was crushed and ground to below 60 mesh, and the material was placed in the horizontal fluidized magnetic separation device of Example 1 for magnetic separation for 5 minutes. After magnetic separation, the content of iron oxide in the material was reduced to 1.30%, the content of aluminum oxide was 26%, and the removal rate of iron oxide was 51.25%. After calcination and activation at 750°C for 2 hours, the content of aluminum oxide in the material was 31.14%, and the content of iron oxide was 1.65%; the material after magnetic separation is iron-removed under the following acid leaching conditions: the concentration of hydrochloric acid is 12mol / L (mass fraction is 36%), the solid-liquid ratio is 1:3, acid leaching at 40°C for 40min, this step of acid leaching The iron oxide removal rate of the process is 48%; the total iron oxide removal rate of the two-step ir...

Embodiment 3

[0023] The coal gangue with an alumina content of 21.18%, an iron oxide content of 2.53%, and a carbon content of 25% was crushed and ground to 80 mesh, and the material was placed in the horizontal fluidized magnetic separation device of Example 1 for magnetic separation for 3 minutes, and the magnetic separation The iron oxide content in the final material was reduced to 1.62%, the alumina content was 22%, and the removal rate of iron oxide was 42.37%. After calcination and activation at 750°C for 2 hours, the alumina content was 29.33%, and the iron oxide content was reduced to 2.16%. ; The material after magnetic separation should be iron-removed under the following acid leaching conditions. According to the solid-to-liquid ratio of 1:3, add hydrochloric acid with a concentration of 10mol / L (mass fraction: 30%), and pickle at 50°C for 30 minutes. The iron oxide removal rate of the process is 49%; the total iron oxide removal rate of the two-step iron removal is 70.61%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com