Closed type aeration reactor

A reactor, closed technology, used in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of high power requirements of pumps and fans, low oxygen utilization rate, and easy damage. , to achieve the effect of improving power efficiency, improving utilization efficiency, and improving oxygen utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

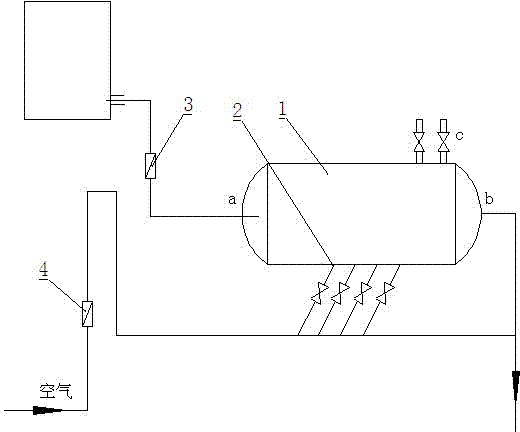

[0018] like figure 1 As shown, it mainly includes a reactor, which is a closed pool structure, and the pool body 1 can be in the shape of a cuboid or a cylinder according to the actual situation.

[0019] One end of the pool body 1 along the long axis direction is a water inlet a, and the other end is a water outlet b. The side wall of the pool body is distributed with a number of aeration micropores, the aeration microholes are located on the side wall of the pool body 1, and the air intake direction of the aeration microholes is perpendicular to the long axis of the pool body 1.

[0020] The aeration microhole adopts blast or jet aeration device, the aeration device is installed on the side wall of the pool body, and the aeration head of the aeration device is connected to the pool body through welding or adhesive structure at the aeration microhole. In this embodiment, the airflow direction of the aeration head 2 is set in the tangent direction of an inscribed circle with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com