Steel-casting brick for producing high-grade special alloy steel and production method thereof

A kind of alloy steel and special technology, applied in the field of poured steel bricks, can solve the problems of being difficult to adapt to ultra-high temperature resistance, high corrosion resistance, etc., and achieve the effect of being conducive to mass industrial production, high strength, and reasonable auxiliary measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] specific implementation The way is:

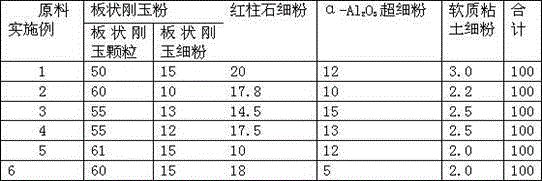

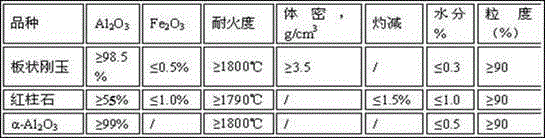

[0038] (1) Selection of raw materials: Purchasing raw materials according to the technical requirements of raw materials used in the technical production of the present invention, wherein the main raw material tabular alumina requires good sintering, the specific embodiment is that the body density must reach the technical index, and the raw material of tabular alumina is processed by the supplier 3mm ~ 1mm, and 1mm ~ 0mm granular material, the particle size requires a pass rate of 90% and above, packed in a bag of 25Kg, and the other part of the tabular corundum is finely ground and processed into 325 mesh (-0.045mm) fine powder, requiring 90% and above Pass rate, 25Kg in a bag, andalusite is required to be processed into 200 mesh (-0.076mm) fine powder, α-Al 2 o 3 Ultrafine powder can be purchased in the market according to requirements, and high-quality clay can be processed into fine powder by purchasing blocks, or directly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com