Soles of ejection foamed rubber-plastic sports shoes and manufacturing method of soles

A manufacturing method, technology of sports shoes, applied in the field of soles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

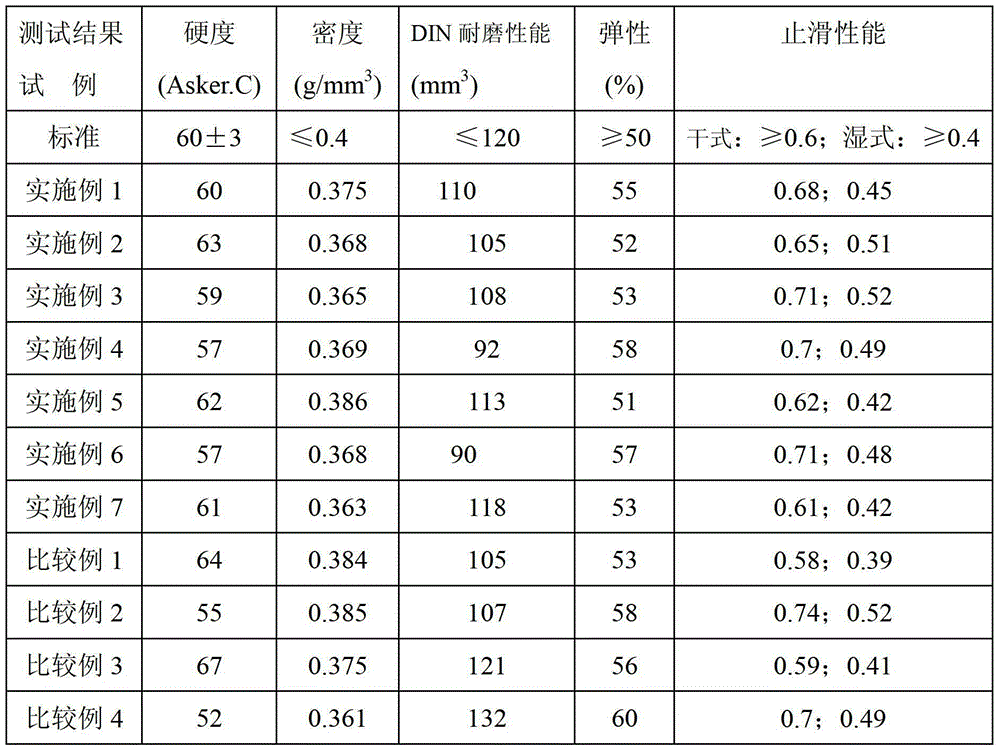

Examples

Embodiment 1

[0050] Embodiment 1: The method for preparing the sole of the foamed rubber and plastic sports shoes of the present invention comprises the following steps,

[0051] 1. The composition of raw materials by mass percentage is as follows:

[0052] Ethylene-vinyl acetate copolymer 7470M: 40%;

[0053] Ethylene-vinyl acetate copolymer 40W: 13%;

[0054] Ethylene-octene copolymer LC-168: 13%;

[0055] Hydrogenated styrene-butadiene-styrene block copolymer: 10%;

[0056] EPDM 3722P: 7%;

[0057] Polysiloxane resin: 6%;

[0059] Stearic acid: 0.4%;

[0062] Dicumyl peroxide: 0.8%;

[0063] Azodicarbonamide: 1.0%;

[0064] Masterbatch: 2.6%.

[0065] 2. the manufacture method of the described injection foam rubber and plastic sports shoe sole, it is characterized in that comprising the following steps:

[0066] 1) Pound material

[0067] Weigh the raw materials according to the designed form...

Embodiment 2

[0080] Embodiment 2: adjust EVA7470M on the basis of embodiment 1, 40W, the consumption of LC-168, SEBS, 3722P, its raw material formula is as follows:

[0081] Ethylene-vinyl acetate copolymer 7470M: 45%;

[0082] Ethylene-vinyl acetate copolymer 40W: 15%;

[0083] Ethylene-octene copolymer LC-168: 10%;

[0084] Hydrogenated styrene-butadiene-styrene block copolymer: 8%;

[0085] EPDM 3722P: 5%;

[0086] Polysiloxane resin: 6%;

[0088] Stearic acid: 0.4%;

[0090] Zinc oxide: 1.2%;

[0091] Dicumyl peroxide: 0.8%;

[0092] Azodicarbonamide: 1.0%;

[0093] Masterbatch: 2.6%.

Embodiment 3

[0094] Embodiment 3: on the basis of embodiment 2, continue to adjust EVA7470M, 40W, the consumption of LC-168, SEBS, 3722P, make it be controlled within the setting dosage range, its raw material formula is as follows:

[0095] Ethylene-vinyl acetate copolymer 7470M: 40%;

[0096] Ethylene-vinyl acetate copolymer 40W: 10%;

[0097] Ethylene-octene copolymer LC-168: 15%;

[0098] Hydrogenated styrene-butadiene-styrene block copolymer: 12%;

[0099] EPDM 3722P: 6%;

[0100] Polysiloxane resin: 6%;

[0101] Talc powder: 4%;

[0102] Stearic acid: 0.4%;

[0103] Zinc stearate: 1.0%;

[0104] Zinc oxide: 1.2%;

[0105] Dicumyl peroxide: 0.8%;

[0106] Azodicarbonamide: 1.0%;

[0107] Masterbatch: 2.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com