High-wear-resisting land leveler blade and production method

A grader, high wear-resistant technology, applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high cost, complex ion implantation and infiltration tungsten process, low production efficiency, etc., to achieve increased strength and excellent strength , the effect of reducing gas and inclusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

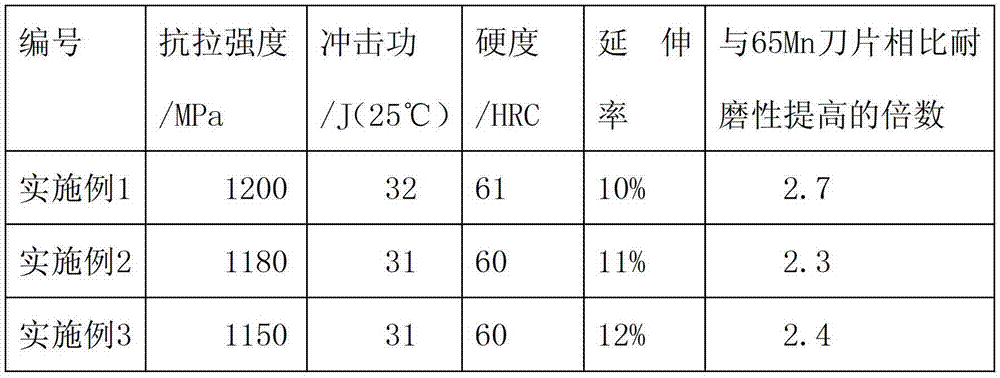

Embodiment 1

[0023] A high wear-resistant grader blade, in terms of weight percentage, the material of the high wear-resistant grader blade is composed of the following components: C: 0.25%, Al: 0.6%, Mn: 1%, W: 1.5%, Si- B-C-N nano-amorphous particles: 0.7%, B: 0.0032%, P: 0.01%, S: 0.009%, and the balance is Fe; the preparation steps of the high wear-resistant motor grader blade are as follows:

[0024] 1) In terms of weight percentage, the composition is C: 0.25%, Al: 0.6%, Mn: 1%, W: 1.5%, B: 0.0032%, P: 0.01%, S: 0.009%, and the balance is Fe Molten steel desulfurization, combined top-bottom blowing in converter, RH vacuum degassing treatment, Si-B-C-N nano-amorphous particles with a weight percentage of 0.7% are pressed in by the flushing method, and the furnace is released when the temperature of molten steel is 1670°C;

[0025] 2) Cast the grader blade slab in the wax mold shell with a preheating temperature of 500°C, and control the cooling time of the grader blade slab casting to...

Embodiment 2

[0029] A high wear-resistant grader blade, in terms of weight percentage, the material of the high wear-resistant grader blade is composed of the following components: C: 0.26%, Al: 0.5%, Mn: 0.9%, W: 1.7%, Si- B-C-N nano-amorphous particles: 0.6%, B: 0.003%, P: 0.015%, S: 0.009%, and the balance is Fe; the preparation method of the high wear-resistant motor grader blade is as follows:

[0030] 1) In terms of weight percentage, the composition is C: 0.26%, Al: 0.5%, Mn: 0.9%, W: 1.7%, B: 0.003%, P: 0.015%, S: 0.009%, and the balance is Fe Desulfurization of molten steel, combined top-bottom blowing of converter, RH vacuum degassing treatment, injection of Si-B-C-N nano-amorphous particles with a weight percentage of 0.6% by punching method, and release when the temperature of molten steel is 1650°C;

[0031] 2) Cast the grader blade slab in the wax mold shell with a preheating temperature of 490°C, and control the cooling time of the grader blade slab casting to 1500°C within ...

Embodiment 3

[0035] A high wear-resistant grader blade, in terms of weight percentage, the material of the high wear-resistant grader blade is composed of the following components: C: 0.27%, Al: 0.4%, Mn: 0.8%, W: 2%, Si- B-C-N nano-amorphous particles: 0.5%, B: 0.003%, P: 0.009%, S: 0.015%, and the balance is Fe; the preparation method of the high wear-resistant motor grader blade is as follows:

[0036] 1) In terms of weight percentage, the composition is C: 0.27%, Al: 0.4%, Mn: 0.8%, W: 2%, B: 0.003%, P: 0.009%, S: 0.015%, and the balance is Fe Desulfurization of molten steel, combined top-bottom blowing of converter, RH vacuum degassing treatment, injection of Si-B-C-N nano-amorphous particles with a weight percentage of 0.5% by punching method, and release when the temperature of molten steel is 1640°C;

[0037] 2) Cast the grader blade slab in the wax mold shell with a preheating temperature of 480°C, and control the cooling time of the grader blade slab casting to 1500°C within 18 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com