Biaxial uniaxial tension device for in-situ structure detection in combination with scattering of X-rays and experimental method thereof

A technology of uniaxial stretching and structure detection, which is applied in the direction of material analysis using radiation diffraction, etc., can solve the problems of reducing experimental efficiency, polymers are easy to sag, and reducing the selection window of experimental samples, so as to achieve precise control, precise temperature, Effect of strain rate and strain continuously adjustable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawings and experimental examples.

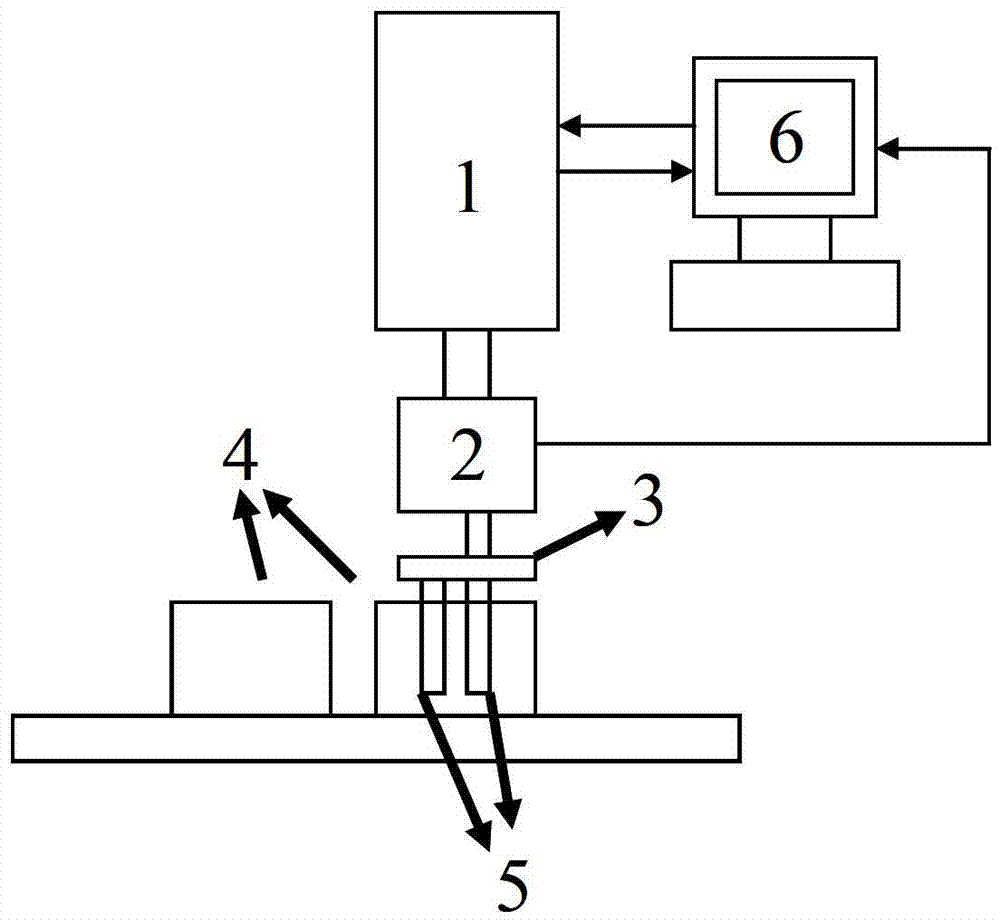

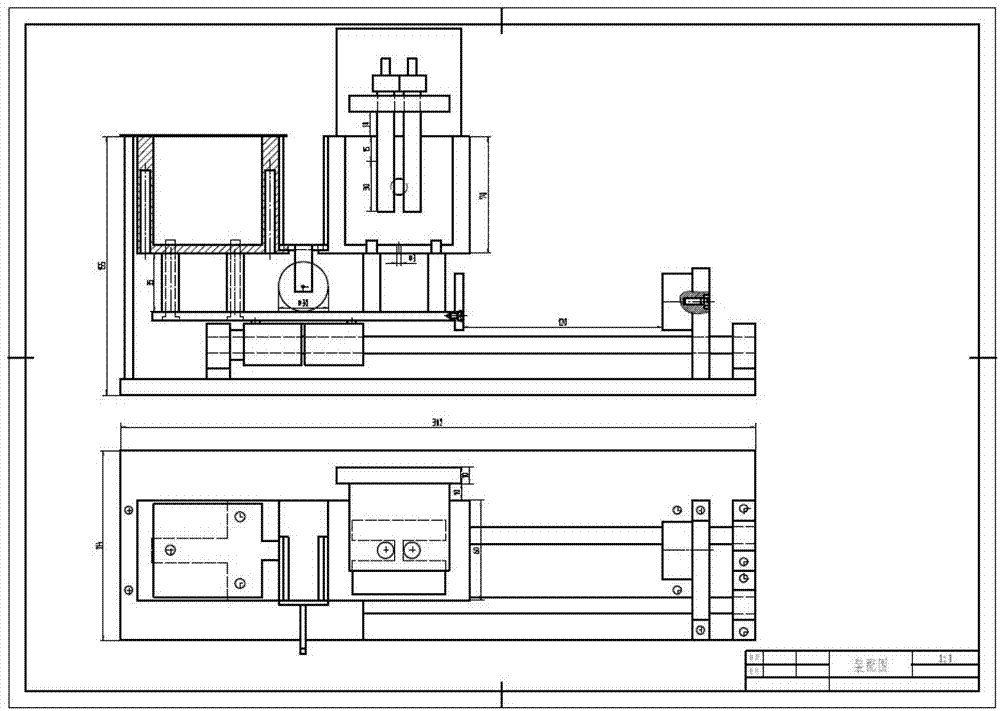

[0044] A biaxial uniaxial stretching device combined with X-ray scattering for in-situ structure detection, see attached figure 1 , which includes a high-precision servo motor 1, a torque sensor 2, a fine gear 3, a heating furnace 4, a reverse stretching shaft 5, and a Labview software control system 6, wherein:

[0045] The device uses a high-precision servo motor 1 as a rotating power system;

[0046] The device uses a torque sensor 2 to make statistics on the torque change during the stretching process;

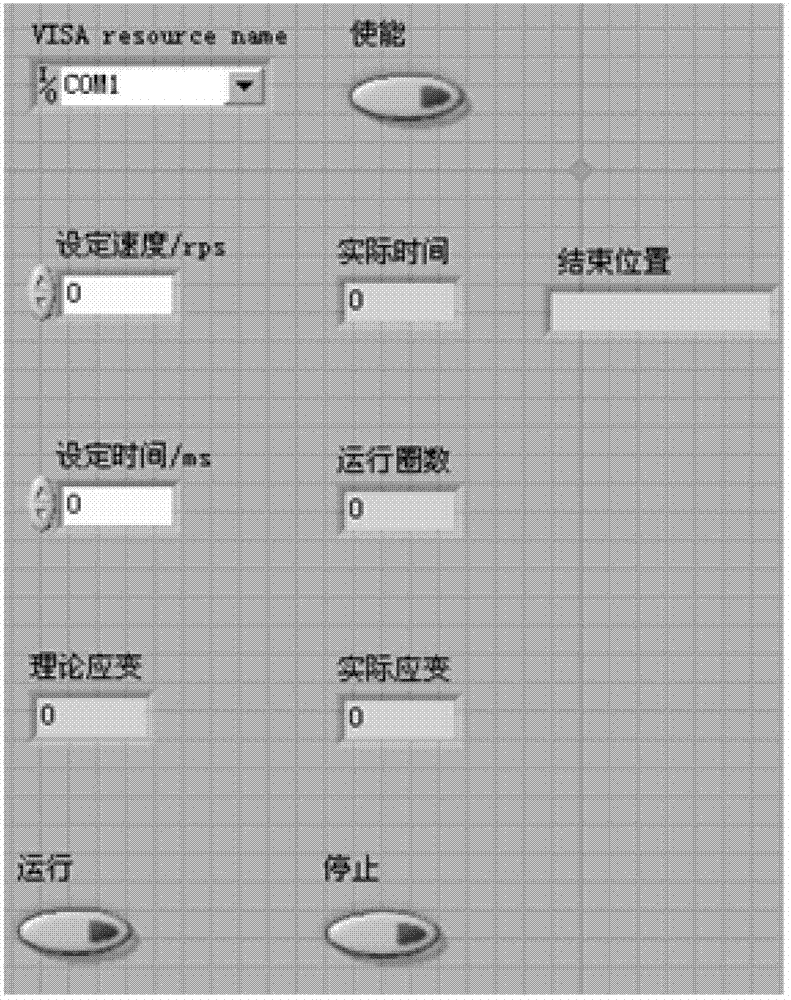

[0047]The device uses Labview software to write the Labview software control system 6. The Labview software control system 6 controls the high-precision servo motor 1 and collects data, and controls the torque of the torque sensor 2 with the applied tensile strain and strain rate. Integrated, can control and data acquisition synchronously; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com