Ultrafiltration membrane pool with secondary on-line coagulation function

An ultrafiltration membrane and functional technology, applied in the field of ultrafiltration membrane pools, can solve the problems of uneven water inflow, high operating energy consumption, impacting membrane components across the membrane pressure difference, etc., achieve smooth sludge discharge, reduce operating energy consumption, The effect of reducing the transmembrane pressure difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

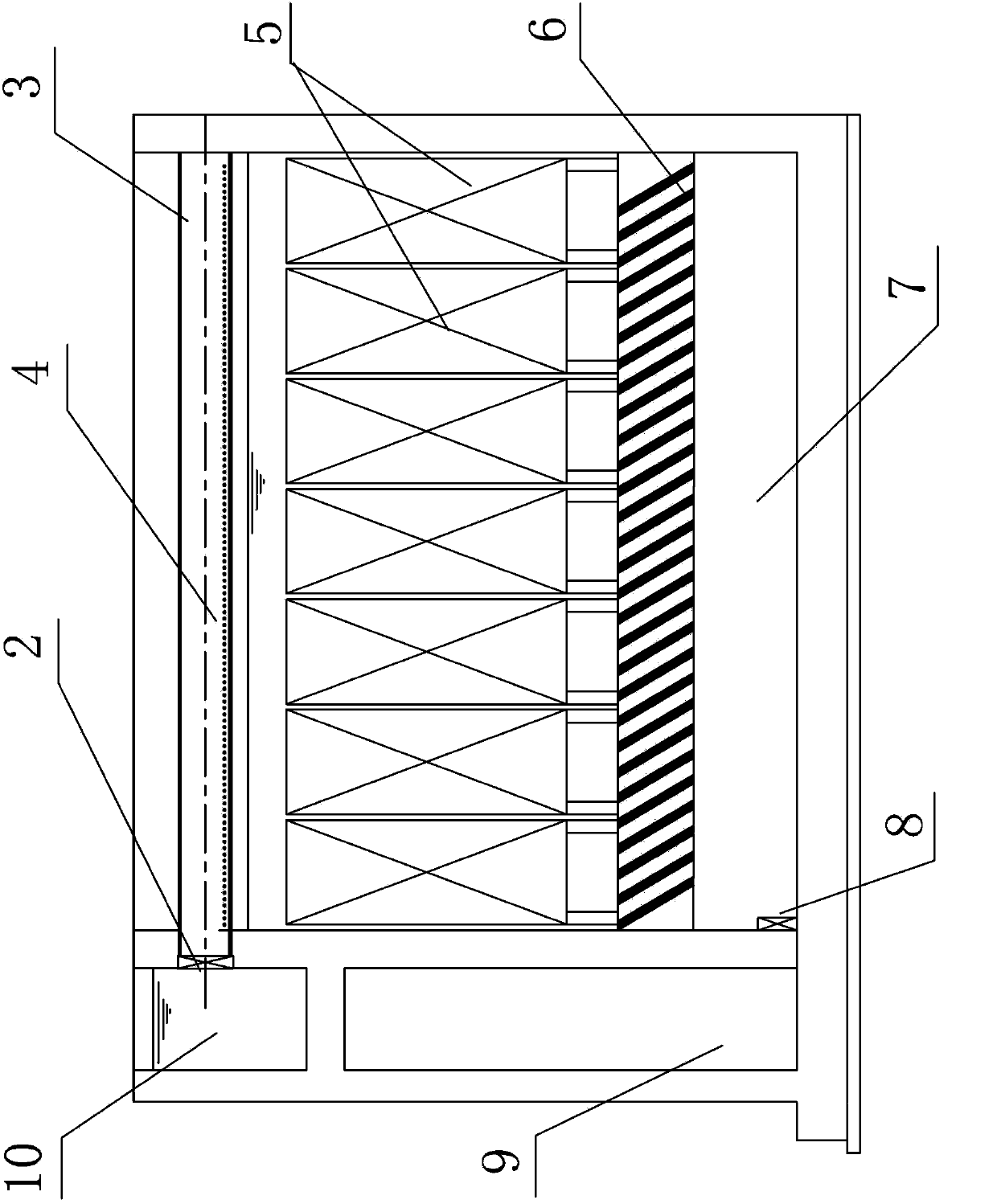

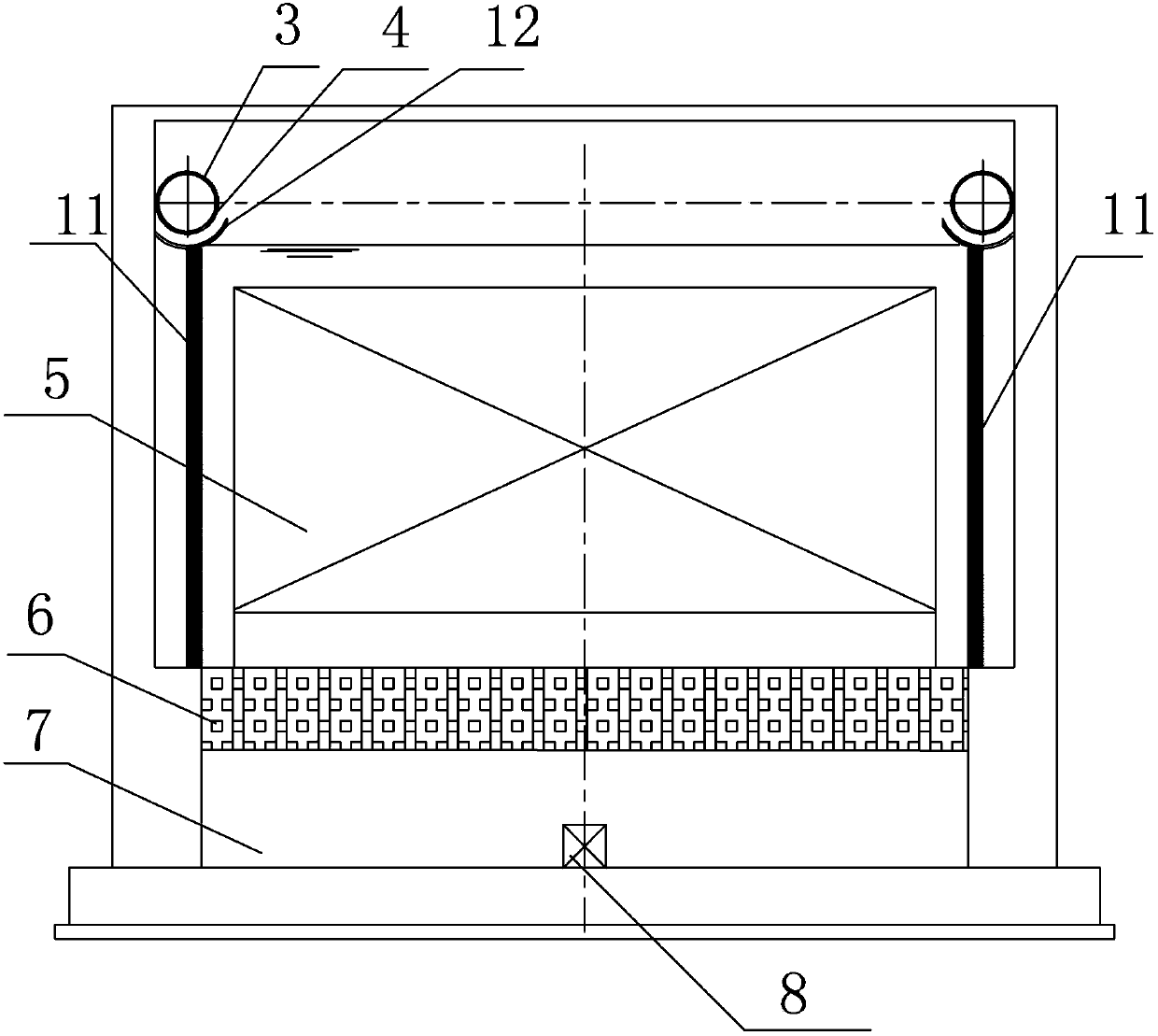

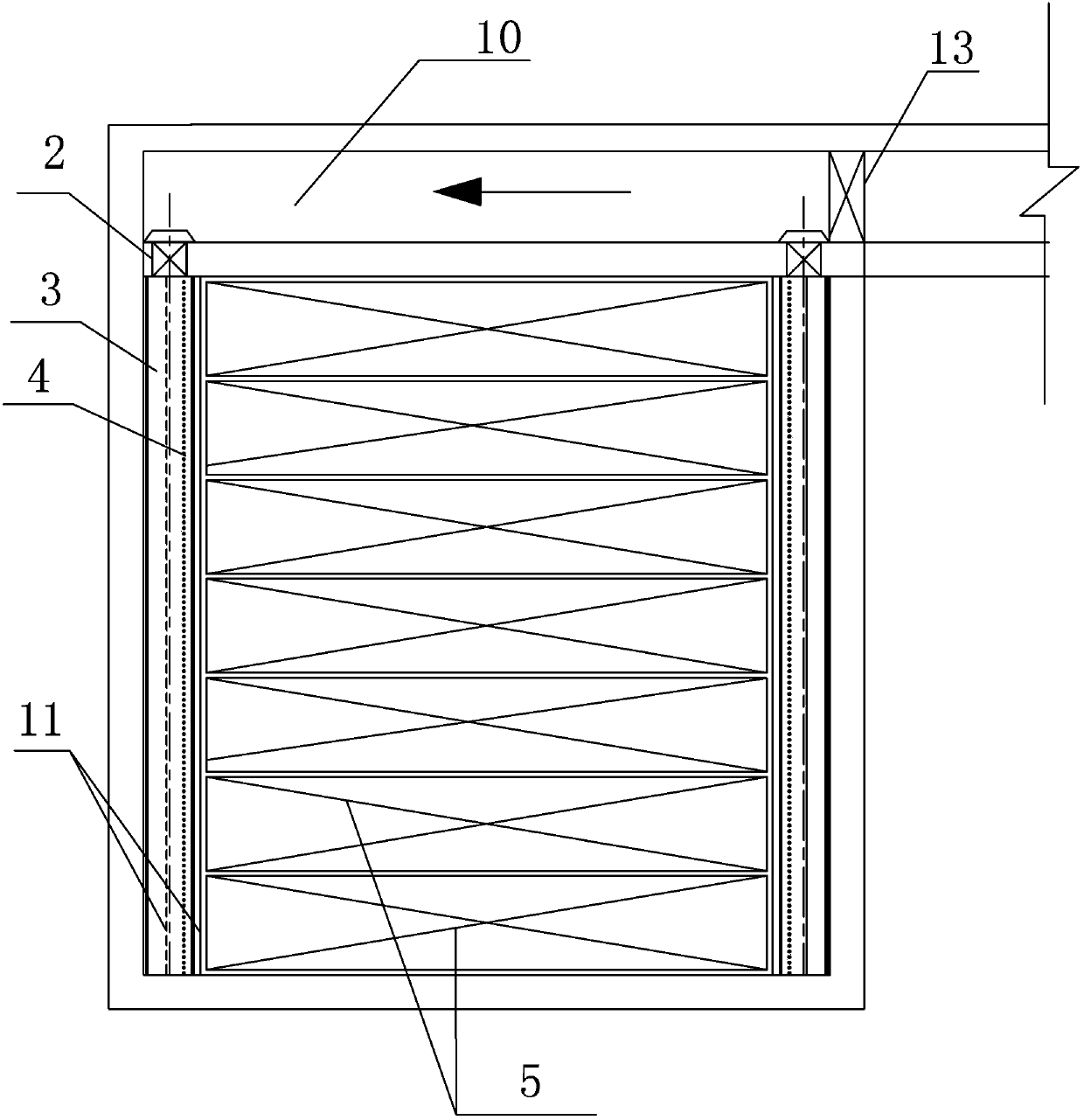

[0011] Specific implementation mode one: as Figure 1~3 As shown, the ultrafiltration membrane tank with secondary online coagulation function in this embodiment includes a main water inlet channel 10, a drainage channel 9, two energy dissipation weirs 12, two perforated grids 11, and two main pipe control valves 2. A plurality of membrane modules 5, a plurality of inclined plates 6, two main pipes 3 with water distribution holes and a plurality of liquid level control valves 13; the main water inlet channel 10 and the drainage channel 9 are located on the side wall of the membrane tank, and the The main water channel 10 is arranged above the drainage channel 9 and both are arranged horizontally. A plurality of membrane modules 5 are sequentially arranged in the membrane pool along the length direction, and a plurality of inclined plates 6 are arranged below the membrane modules 5. Arranged parallel to each other, the sludge area 7 is located under the plurality of inclined pl...

Embodiment

[0013] The raw water quality of a source water in the Pearl River after coagulation and sedimentation is as follows: turbidity is 4.28-4.92NTU, temperature is 30.8-31.5°C, pH value is 7.3-7.48, COD Mn 0.81-0.95mg / L, UV 254 0.015-0.019cm -1 , the optimal coagulant dosage is 0.6mg / L (based on Al 2 o 3 The membrane pollution is alleviated, the effluent water quality is guaranteed, the secondary online coagulation does not affect the chemical cleaning of the membrane, and the transmembrane pressure difference of the polluted membrane can be completely restored after being cleaned by sodium hypochlorite.

[0014] Calculation:

[0015] A. To ensure uniform outflow, such as Figure 4 shown

[0016] Let the flow velocity at the inlet of the main water distribution pipe 3 be ν

[0017] Q 0 The initial flow and initial pressure head of the main water distribution pipe on each side is H 1 ;The flow velocity at the end of the pipe is zero, and the pressure head is H 2 ;

[001...

specific Embodiment approach 2

[0083] Specific implementation mode two: as figure 1 As shown, the inclination angle of the swash plates 6 in this embodiment is 50-60 degrees, and the distance between two adjacent slant plates 6 is 35 mm. Such setting ensures smooth mud discharge. Other components and connections are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com