Preparation method of graft modified polytetrafluoroethylene (PTFE) microporous membrane with lasting hydrophilism

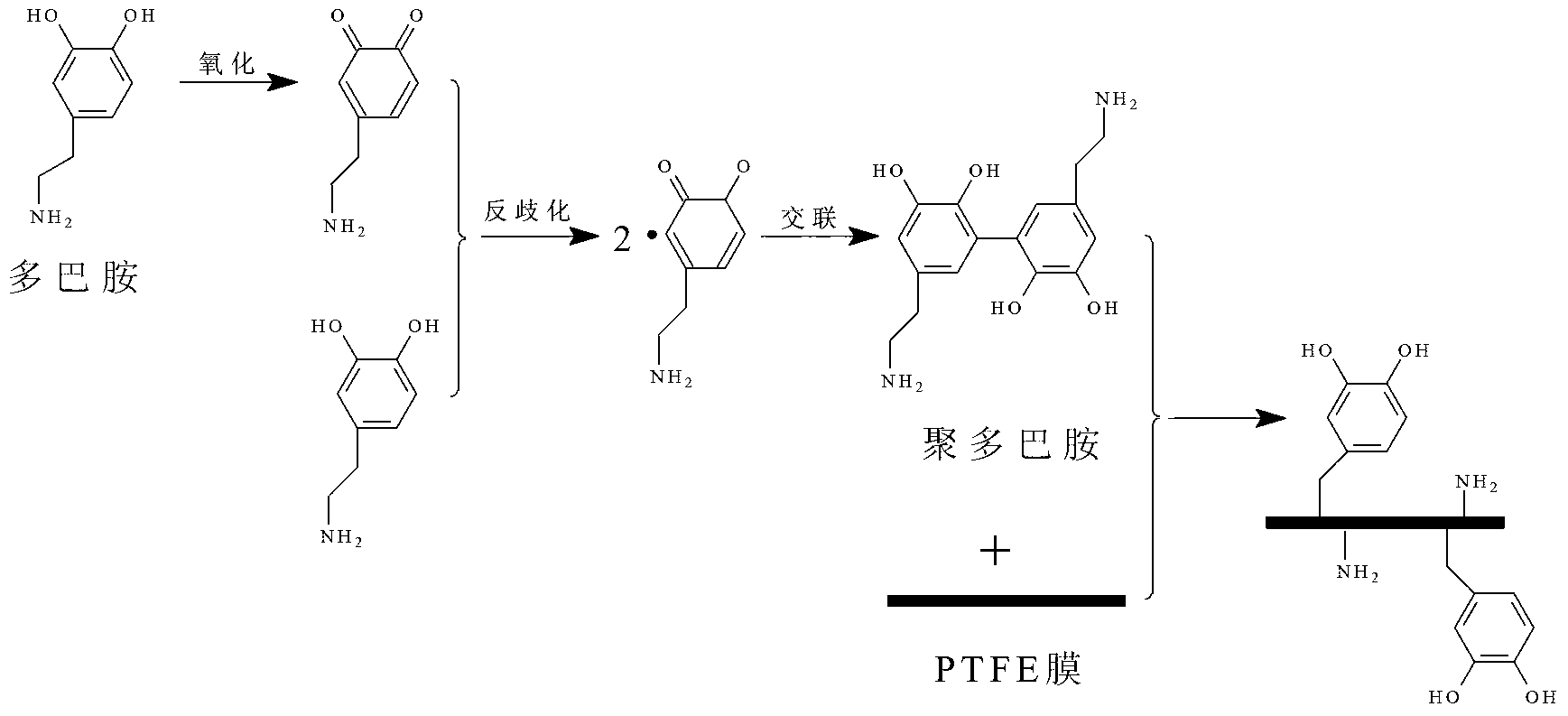

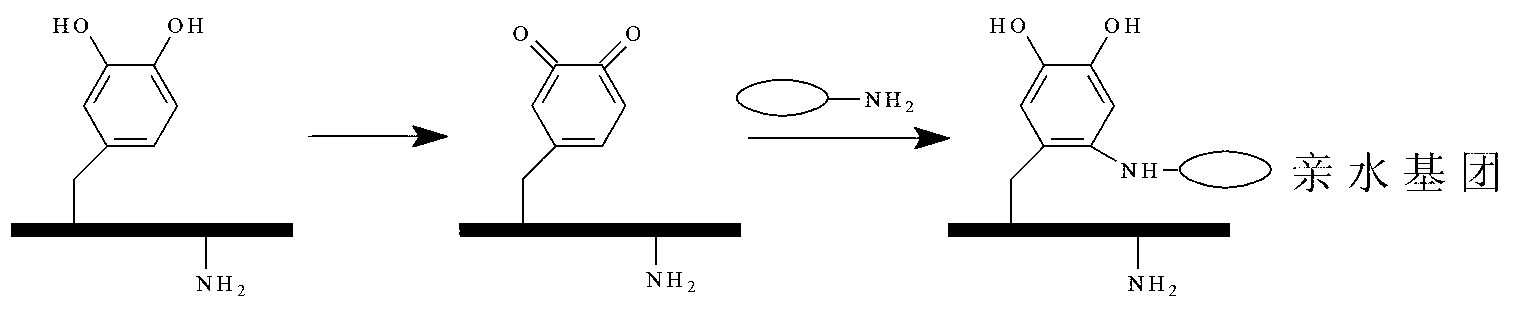

A graft-modified, PTFE technology is applied in the field of preparation of a graft-modified PTFE microporous membrane with durable hydrophilicity, and can solve the problems of unstable modification effect, damage to the structure of the membrane body, complicated equipment and the like, To achieve the effect of long-term hydrophilic performance, simple preparation process and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

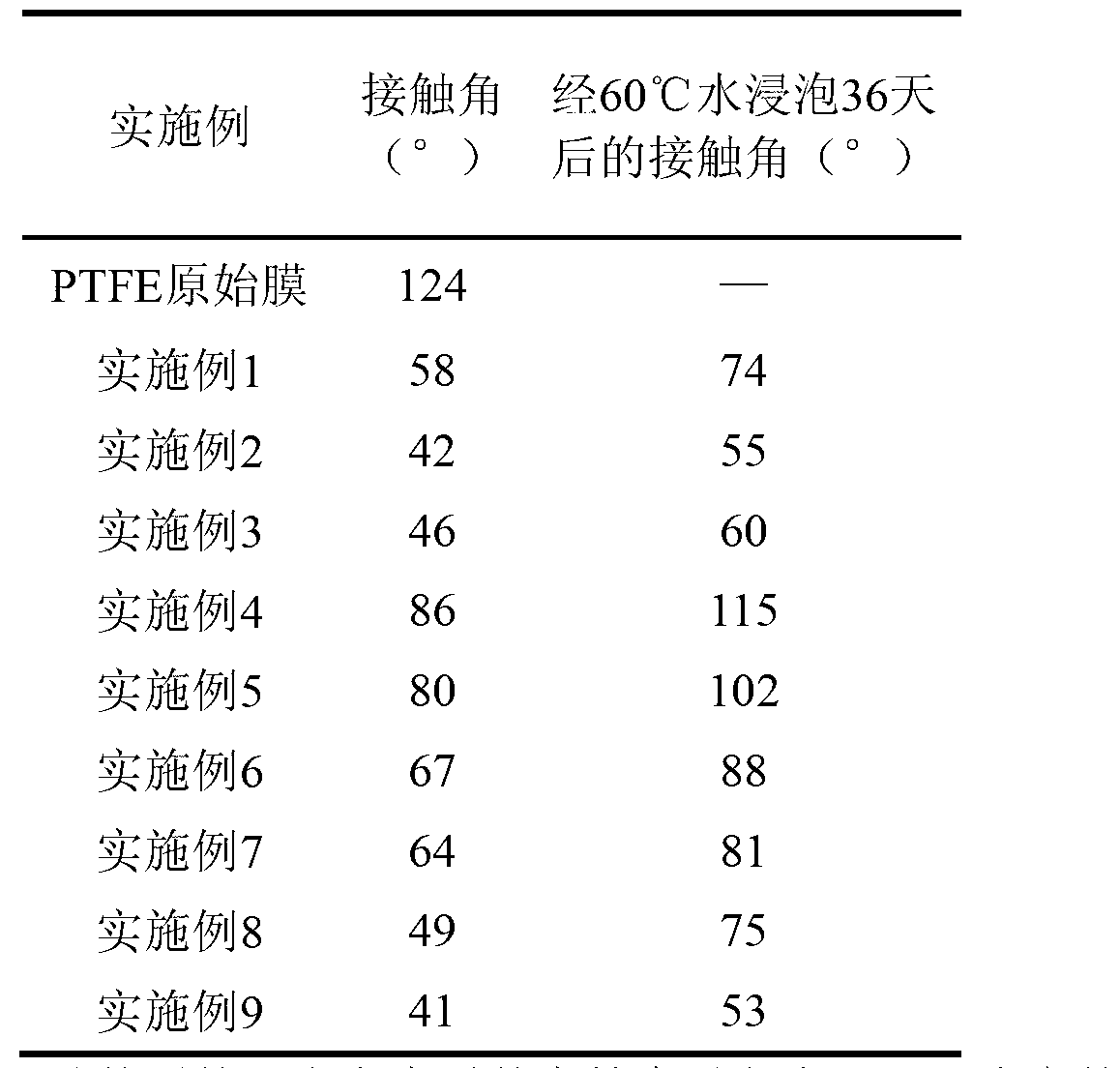

Examples

Embodiment 1

[0029] A kind of preparation method with persistent hydrophilic graft modified PTFE microporous membrane, concrete steps are as follows:

[0030] 1) Prepare a dopamine aqueous solution with a concentration of 0.1g / L, use Tris-HCl buffer to adjust the pH value of the solution to 8.5, soak the PTFE microporous membrane in ethanol until it is transparent, and then immerse it in the dopamine aqueous solution at room temperature for 24 hours;

[0031] 2) Select diethanolamine as the modifier, prepare an aqueous solution of diethanolamine with a concentration of 4g / L, use Tris-HCl buffer to adjust the pH value of the solution to 8.5, and immerse the PTFE microporous membrane treated in step 1) in diethanolamine 1h in aqueous solution;

[0032] 3) The PTFE microporous membrane treated in step 2) is taken out and dried to obtain a graft-modified PTFE microporous membrane with persistent hydrophilicity.

Embodiment 2

[0034] 1) Prepare a dopamine aqueous solution with a concentration of 2g / L, adjust the pH value of the solution to 8.5 with Tris-HCl buffer, soak the PTFE microporous membrane in ethanol until it is transparent, and then immerse it in the dopamine aqueous solution at room temperature for 24 hours;

[0035] 2) Select diethanolamine as the modifier, prepare an aqueous solution of diethanolamine with a concentration of 10g / L, use Tris-HCl buffer to adjust the pH value of the solution to 7, and immerse the PTFE microporous membrane treated in step 1) in diethanolamine 0.5h in aqueous solution;

[0036] 3) The PTFE microporous membrane treated in step 2) is taken out and dried to obtain a graft-modified PTFE microporous membrane with persistent hydrophilicity.

Embodiment 3

[0038] 1) Prepare a dopamine aqueous solution with a concentration of 2g / L, adjust the pH value of the solution to 8.5 with Tris-HCl buffer, soak the PTFE microporous membrane in ethanol until it is transparent, and then immerse it in the dopamine aqueous solution at room temperature for 24 hours;

[0039] 2) Select aminopolyethylene glycol as a modifier, prepare an aqueous solution of aminopolyethylene glycol with a concentration of 10g / L, use Tris-HCl buffer to adjust the pH value of the solution to 10, and micronize the PTFE treated in step 1). The porous membrane is immersed in an aqueous solution of aminopolyethylene glycol for 0.5h;

[0040] 3) The PTFE microporous membrane treated in step 2) is taken out and dried to obtain a graft-modified PTFE microporous membrane with persistent hydrophilicity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com