Spouted bed reactor and olefin polymerization method thereof

A technology of reactor and spouted bed, which is applied in the field of olefin polymerization, can solve the problems of slowing down flow velocity, deterioration of solid particle axial flow mixing, and failure to eliminate stagnation zone, so as to promote flow and improve particle movement , Improve the effect of heat transfer efficiency and mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

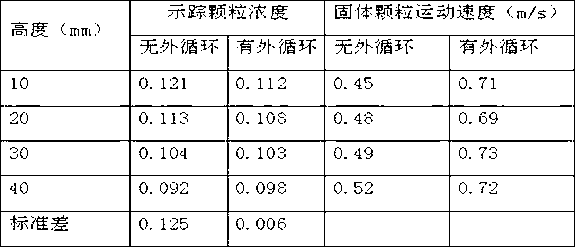

[0050] Example 1 and Comparative Example 1 are the results of laboratory cold model experiments. The main purpose is to compare the effect of external circulation of solid particles on the velocity of solid particles in the annulus area and the mixing of axial particles in the reactor by comparing with Comparative Example 1.

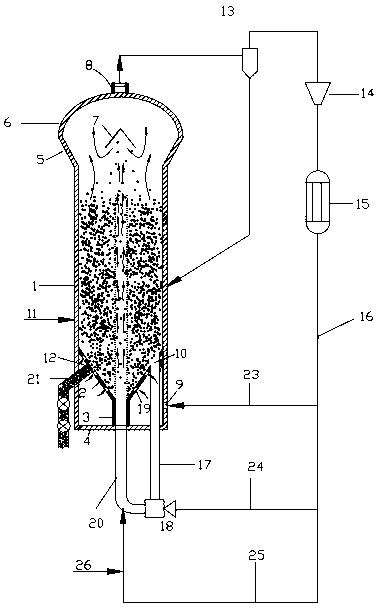

[0051] The structure of the spouted bed reactor cold model experimental device is as follows: figure 1 shown. and figure 1 The difference is that the cold mold experimental device does not have a gas external circulation system. The compressed air from the air compressor is measured by a glass rotameter and divided into three strands, one as the main airflow, the other as the auxiliary airflow, and the third as the auxiliary airflow. Gas-solid jet pump delivery gas. The diameter of the spouted bed reactor in the cold model experimental device is D = 150 mm, and the cylinder height H = 1000 mm. The size parameters of other parts of the spouted bed reac...

Embodiment 2

[0062] Example 2 and Comparative Example 2 are the results of industrial pilot thermal model experiments, the main purpose of which is to investigate the effect of external circulation of solid particles on particle agglomeration through comparison with Comparative Example 2.

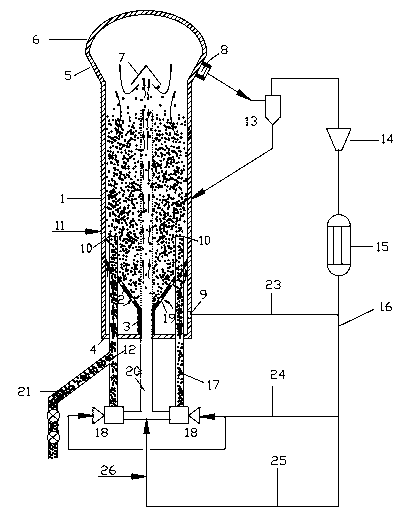

[0063] The structure of the industrial test device is as follows figure 2 shown. In the industrial experimental device, the diameter of the spouted bed reactor is D=420 mm, and the cylinder height H=2500 mm. The size parameters of other parts of the spouted bed reactor and the main parameters of the external circulation system of solid particles are shown in Table 3.

[0064] Table 3 The main parameters of the industrial experimental device

[0065] cylinder diameter D Conical Baffle Bottom Diameter 0.4D cylinder height H Conical Baffle Height 0.05H Expanded section diameter 1.8D Quantity of solid particle conveying system 2 Extended section height 0.2H Solid p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com