Preparation and application of solid super alkali catalyst

A solid super base and catalyst technology, which is applied in the preparation of organic compounds, physical/chemical process catalysts, carboxylic acid nitrile preparation, etc., can solve the problems of high reaction temperature and long reaction time, achieve small dosage, save time and Energy consumption, the effect of simple and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

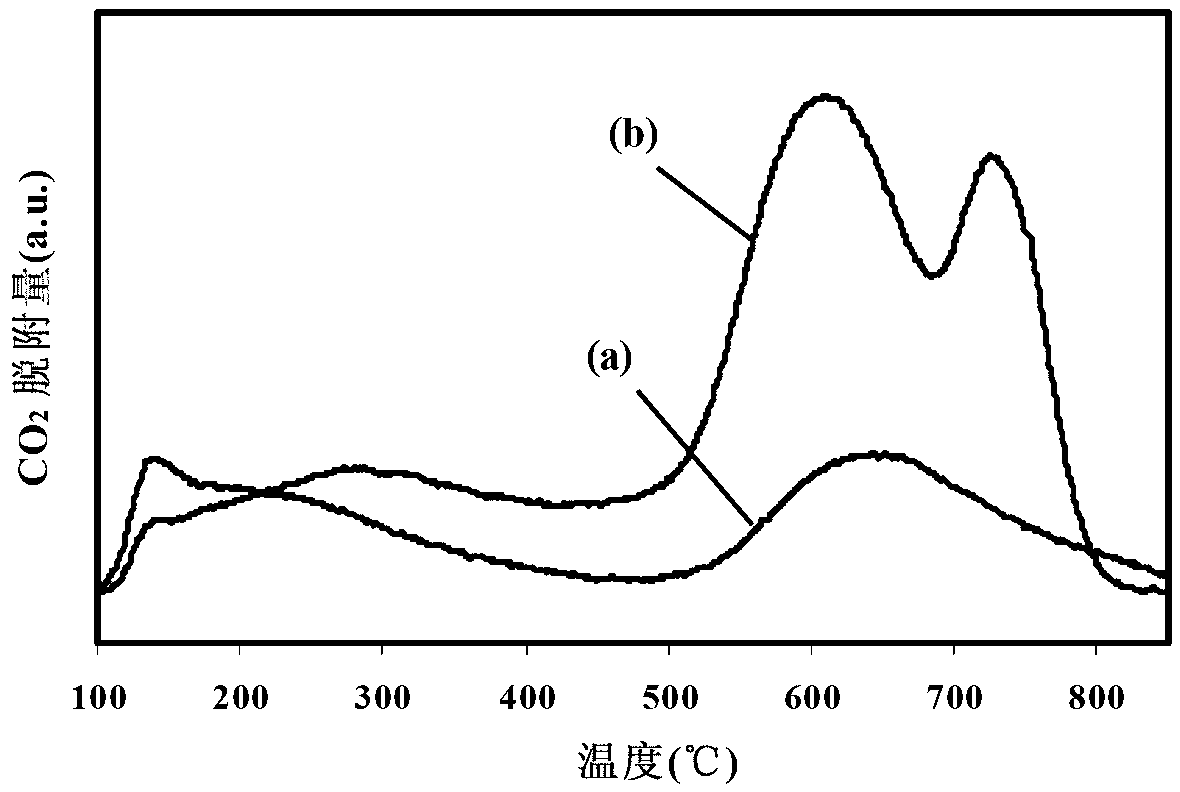

Embodiment 1

[0019] Weigh 3.846 grams of Mg(NO 3 ) 2 ·6H 2 O and 1.876 grams of Al(NO 3 ) 3 9H 2 Dissolve O in 40mL water and 40mL ethanol to make a solution; while stirring, add 1mol / L KOH dropwise into the solution through a constant pressure funnel until the pH of the solution is 10-12, stop the dropwise addition, and continue stirring for 1h ; Heat up to 93°C in an oil bath, condense and reflux for 24 hours, centrifuge, wash with 50ml of water, dry overnight, and then place in a roasting furnace, N 2 Under protection, the room temperature was raised to 550°C at a rate of 5°C / min, and kept at 550°C for 3 hours to obtain a 10.32% potassium-doped magnesia-alumina solid superbase catalyst.

[0020] Take by weighing 0.212 gram benzaldehyde and 0.226 gram ethyl cyanoacetate respectively, add in the reaction vessel, add 1ml DMF as solvent, the solid super base catalyst that 0.019 gram present example makes is joined in the reactor; Under stirring condition, React at room temperature for...

Embodiment 2

[0022] Weigh 3.846 grams of Mg(NO 3 ) 2 ·6H 2 O and 1.876 grams of Al(NO 3 ) 3 9H 2 O was dissolved in 40mL water and 40mL ethanol to make a solution; while stirring, an excess of 1mol / L KOH was added dropwise to the solution through a constant pressure funnel until the pH of the solution was 10-12, stop the dropwise addition, and continue Stir for 1h; heat up to 93°C in an oil bath, condense and reflux for 24h, centrifuge, wash with 200ml water until neutral, dry overnight, then place in a roaster, N 2 Under protection, the room temperature was raised to 550°C at a rate of 5°C / min, and kept at 550°C for 3 hours to obtain a solid base catalyst of magnesia aluminum oxide.

[0023] Weigh 0.212 grams of benzaldehyde and 0.226 grams of ethyl cyanoacetate respectively, add to the reaction vessel, add 1ml of DMF as a solvent, and add 0.019 grams of the catalyst prepared in this example into the reactor; under stirring conditions, react at room temperature for 1 hour , filtered...

Embodiment 3

[0025] Weigh 2.564 grams of Mg(NO 3 ) 2 ·6H 2 O and 1.876 grams of Al(NO 3 ) 3 9H 2 O was dissolved in 40mL water and 40mL ethanol to make a solution; while stirring, an excess of 1mol / L KOH was added dropwise to the solution through a constant pressure funnel until the pH of the solution was 10-12, stop the dropwise addition, and continue Stir for 1h; heat up to 93°C in an oil bath, condense and reflux for 24h, centrifuge, wash with 200ml water until neutral, dry overnight, then place in a roaster, N 2 Under protection, the room temperature was raised to 550°C at a rate of 5°C / min, and kept at 550°C for 3 hours to obtain a solid base catalyst of magnesia aluminum oxide.

[0026] Weigh 0.212 grams of benzaldehyde and 0.226 grams of ethyl cyanoacetate respectively, add to the reaction vessel, add 1ml of DMF as a solvent, and add 0.019 grams of the catalyst prepared in this example into the reactor; under stirring conditions, react at room temperature for 1 hour , filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com