T type high power ultrasonic transducer

An ultrasonic and transducer technology, applied in the field of T-type high-power ultrasonic transducers, can solve the problem of transducer vibration speed, vibration displacement and large longitudinal stress, limiting transducer acoustic wave radiation area and radiation power, radiation power and sound wave radiation area limitation, to achieve the effect of large diameter, high power operation, and improved radiation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

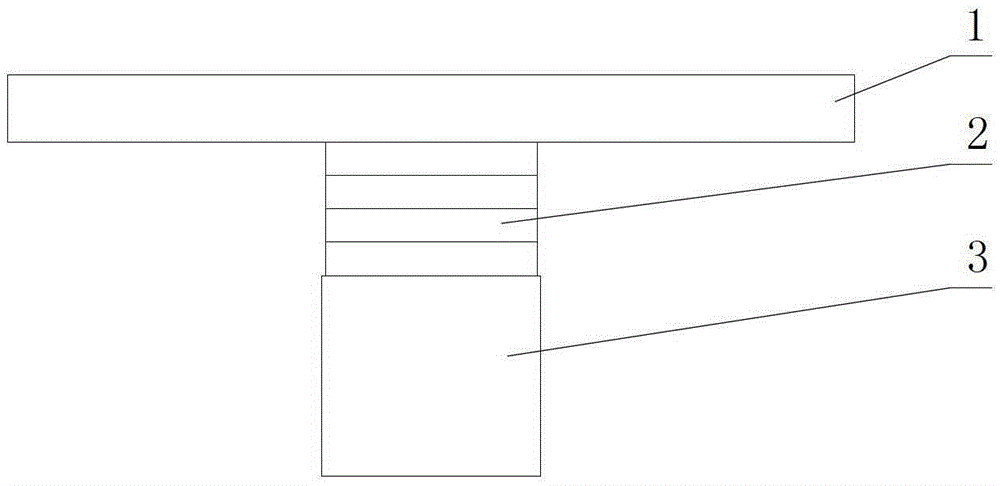

[0017] This embodiment takes the T-type high-power ultrasonic transducer of 20 kilohertz as an example, by figure 1 It can be seen that the ultrasonic transducer in this embodiment is composed of a vibration plate 1 , a piezoelectric ceramic stack 2 and a rear cover 3 .

[0018] The vibrating plate 1 of this embodiment is made of high-strength, low-loss light metal material. This implementation is made of aluminum alloy material. Its geometric shape is a disc shape, its diameter is 180 mm, and its thickness is 18 mm. The central position of the piezoelectric ceramic stack 2 is connected by high-strength metal bolts. The piezoelectric ceramic stack 2 is composed of 4 piezoelectric ceramic sheets coaxially stacked into a cylinder with a thickness of 24mm. The thickness of each piezoelectric ceramic sheet is The diameter is 6mm, and the diameter is 60mm, that is, the diameter of the vibrating plate 1 is three times the diameter of the piezoelectric ceramic sheet, and the piezoele...

Embodiment 2

[0020] This embodiment takes the T-shaped high-power ultrasonic transducer of 25 kHz as an example. The geometric shape of the vibration plate 1 is a disc shape, its diameter is 260 mm, and its thickness is 21 mm. The metal bolts are connected with a piezoelectric ceramic stack 2. The piezoelectric ceramic stack 2 is coaxially stacked with 4 piezoelectric ceramic sheets to form a cylinder with a thickness of 24mm. Each piezoelectric ceramic sheet has a thickness of 6mm and a diameter of 50mm. That is, the diameter of the vibrating plate 1 is 5.2 times the diameter of the piezoelectric ceramic sheet, and the piezoelectric ceramic sheets are bonded and fixed by superglue, and a rear cover 3 is fixed on the other end of the piezoelectric ceramic stack 2, and the rear cover 3 adopts Made of high-strength, low-loss steel material, its geometric shape is disc-shaped, with a diameter of 52mm, which is 1.04 times the diameter of the piezoelectric ceramic sheet, and the height of the re...

Embodiment 3

[0022] This embodiment takes the T-shaped high-power ultrasonic transducer of 30 kHz as an example. The geometric shape of the vibrating plate 1 is a disc shape, its diameter is 206 mm, and its thickness is 15 mm. The metal bolts are connected with a piezoelectric ceramic stack 2. The piezoelectric ceramic stack 2 is coaxially stacked with 4 piezoelectric ceramic sheets to form a cylinder with a thickness of 24mm. Each piezoelectric ceramic sheet has a thickness of 6mm and a diameter of 50mm. That is, the diameter of the vibrating plate 1 is 4.12 times the diameter of the piezoelectric ceramic sheet, and the piezoelectric ceramic sheets are bonded and fixed by superglue, and a rear cover 3 is fixed on the other end of the piezoelectric ceramic stack 2, and the rear cover 3 adopts Made of high-strength, low-loss steel material, its geometric shape is disc-shaped, with a diameter of 52mm, which is 1.04 times the diameter of the piezoelectric ceramic sheet, and the height of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com