Method for producing wet-process phosphoric acid from low-grade phosphate rock

A wet-process phosphoric acid, low-grade technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high acid-insoluble impurity content, difficult comprehensive utilization, low washing rate, etc., and achieve simplified phosphorus enrichment The effect of improving the process, improving the utilization value, and improving the quality of phosphoric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

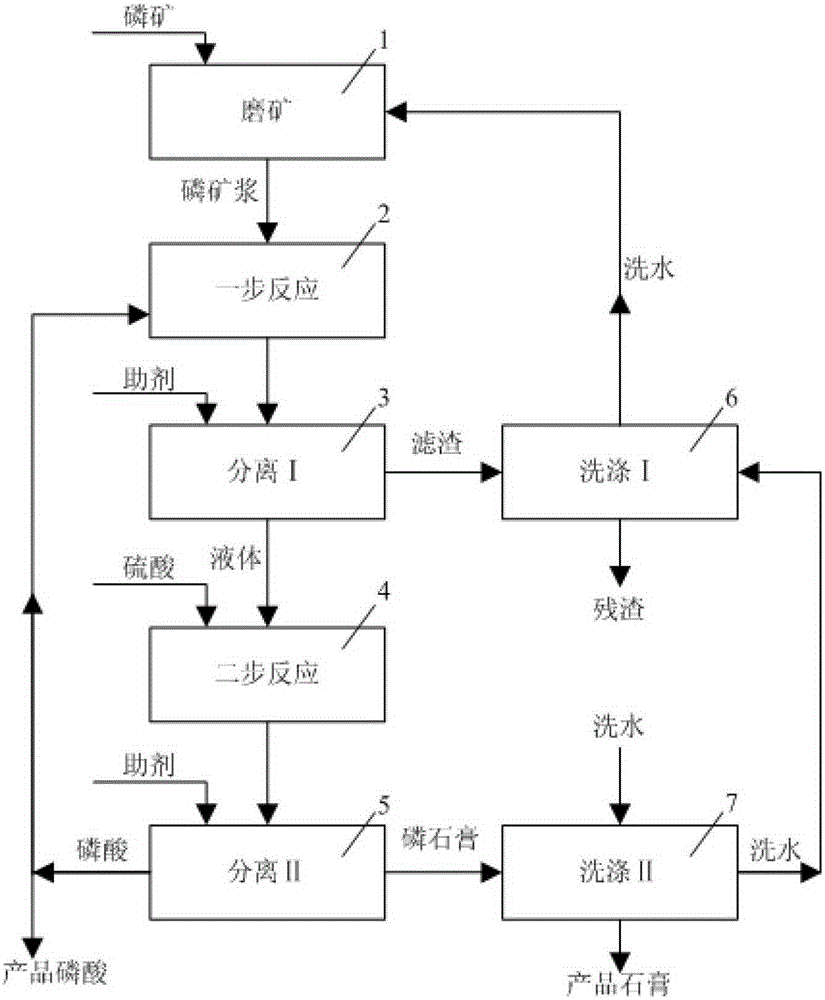

[0034] The method for producing wet-process phosphoric acid by utilizing low-grade phosphate rock comprises the following steps:

[0035] Step 1: Use low-grade phosphate rock (P 2 o 5 =23.00wt%, CaO=40.07wt%, MgO=3.20, Fe 2 o 3 =1.52wt%, Al 2 o 3 =0.55wt%) to prepare phosphate rock slurry, and then with phosphoric acid (P 2 o 5=25.83wt%) for one-step reaction, at a temperature of 42°C to 50°C, react for 3h, the liquid-solid ratio in the extraction slurry=27, after the reaction is completed, add 20ppm of polyacrylamide, 20ppm of modified polyacrylamide, polymerized ferrous sulfate 10ppm was obtained through the separation I operation to obtain the extract clear liquid and filter residue, and the extraction rate was 95.1%;

[0036] Step 2: Add 1 part of the extraction clear liquid and 1.12 times the calculated amount of sulfuric acid into a special reactor, sulfuric acid = 98wt%, maintain the temperature at 80°C to 85°C, and react for 3 hours. Add 20ppm of polyacrylamide...

Embodiment 2

[0039] The method for producing wet-process phosphoric acid by utilizing low-grade phosphate rock comprises the following steps:

[0040] Step 1: Use low-grade phosphate rock (P 2 o 5 =20.07wt%, CaO=43.13wt%, MgO=2.56, Fe 2 o 3 =1.23wt%, Al 2 o 3 =0.67wt%) to prepare phosphate rock slurry, and then with phosphoric acid (P 2 o 5 =35.96wt%) for extraction reaction, at a temperature of 35°C to 42°C, reacted for 8h, the liquid-solid ratio in the extraction slurry = 25, after the reaction was completed, 10ppm of polyacrylamide and 20ppm of modified polyacrylamide were added to extract Clear liquid and filter residue, the extraction rate is 96.12%;

[0041] Step 2: Add 1 part of the extraction clear liquid and 1.20 times the calculated amount of sulfuric acid into a special reactor, sulfuric acid = 92wt%, maintain the temperature at 85°C to 90°C, and react for 6 hours. Add 10ppm of polyacrylamide and 20ppm of modified polyacrylamide to the reaction solution, and after separa...

Embodiment 3

[0044] The method for utilizing low-grade phosphate rock to produce wet-process phosphoric acid comprises the steps:

[0045] Step 1: Use low-grade phosphate rock (P 2 o 5 =21.32wt%, CaO=39.67wt%, MgO=3.18, Fe 2 o 3 =1.19wt%, Al 2 o 3 =0.89wt%) to prepare phosphate rock slurry, and then with phosphoric acid (P 2 o 5 =27.52wt%) for extraction reaction, at a temperature of 48°C to 57°C, reacted for 6h, the liquid-solid ratio in the extraction slurry = 22, after the reaction was completed, 2ppm of polyacrylamide was added and separated to obtain the extract clear liquid and filter residue, the extraction rate 95.67%;

[0046] Step 2: Add 1 part of the extraction clear liquid and 1.09 times the calculated amount of sulfuric acid into a special reactor, sulfuric acid = 96wt%, maintain the temperature at 90°C to 95°C, and fully react for 5 hours. After adding 2ppm of polyacrylamide to the reaction solution and separating II, the liquid is higher quality wet-process phosphori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com