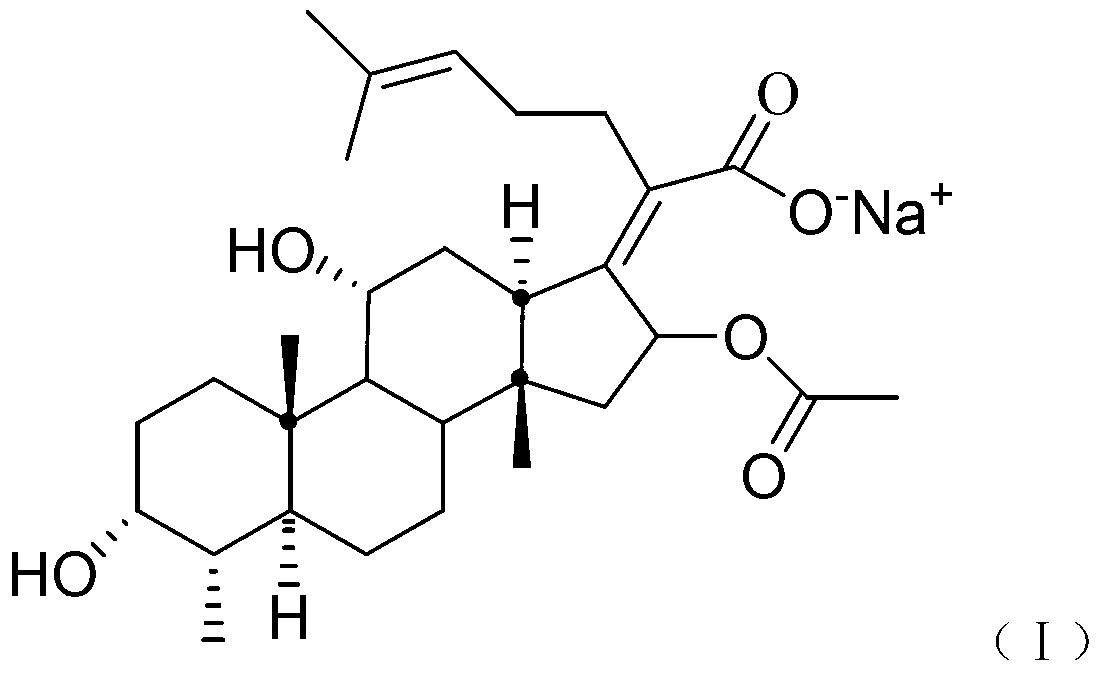

Sodium fusidate crystal and preparation method thereof

A technology for sodium fusidate and crystals, applied in the field of compound crystals and preparation thereof, can solve the problems of high production cost, unfavorable preservation and sub-packaging, poor stability of sodium fusidate crystals, etc., and achieves low production cost and stable production. Sexual and environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

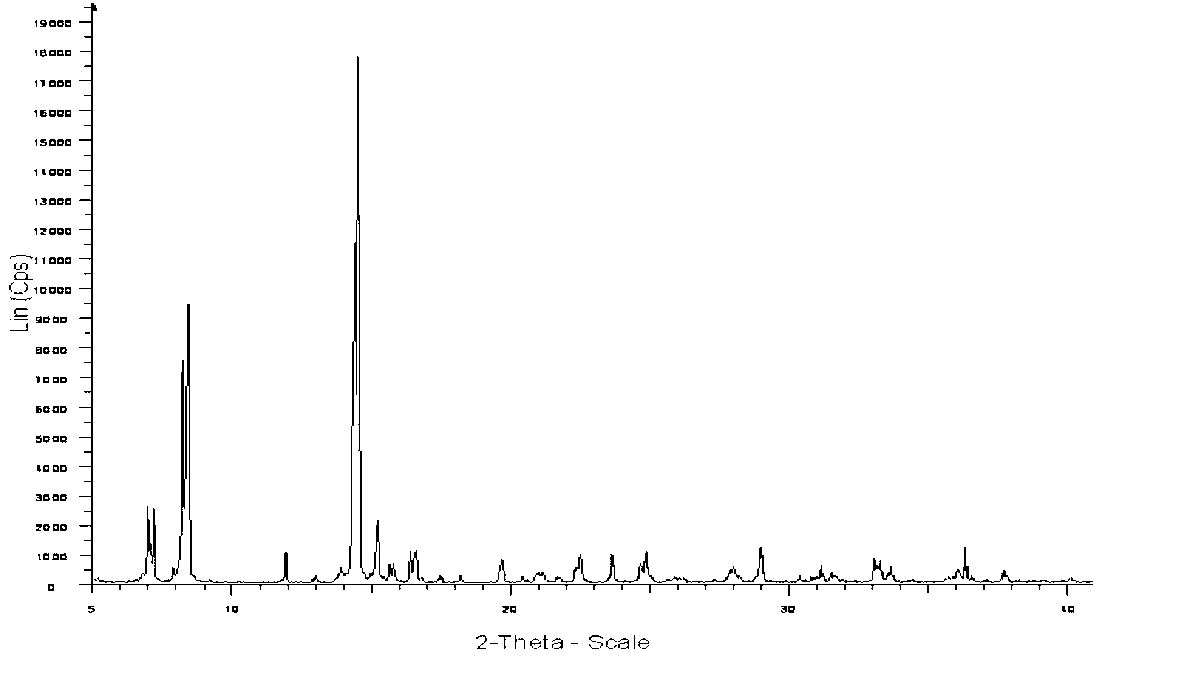

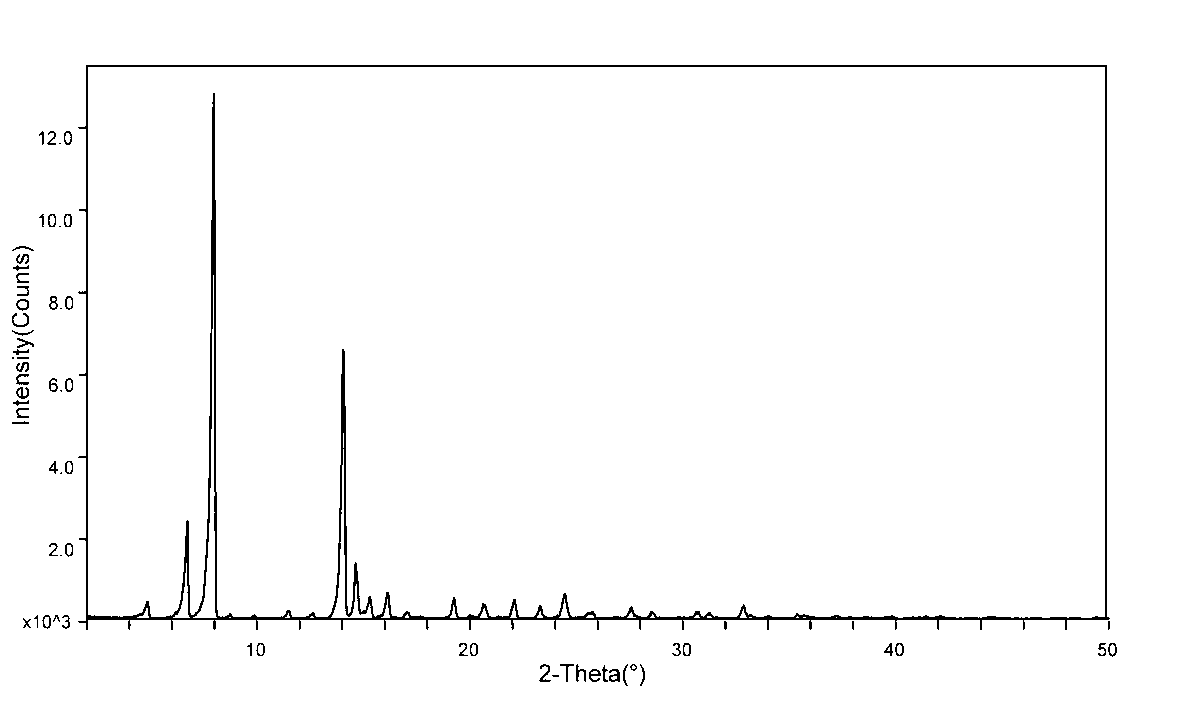

[0027] Weigh 9.0g of fusidic acid solid, add absolute ethanol, heat to 45°C, after dissolving, add 4M aqueous sodium hydroxide solution under stirring, the molar ratio of added sodium hydroxide to fusidic acid is 0.8:1 to obtain 25ml of sodium fusidate solution; control the temperature at 20°C, add ethyl acetate solution under stirring, the flow rate is 25ml / h, when the amount of ethyl acetate is 375ml, stop feeding, Stir for another 0.5 h, filter with suction, and dry the filter cake at 35° C. for 36 h to obtain 8.3 g of sodium fusidate crystals. After testing its X-ray powder diffraction pattern is as follows figure 1 shown. As determined by HPLC, its purity was 99.83%. The yield was 88.46%.

Embodiment 2

[0029] Weigh 9.0g of fusidic acid solid, dissolve it in absolute ethanol at 40°C, add 4M aqueous sodium hydroxide solution under stirring, and the molar ratio of added sodium hydroxide to fusidic acid is 1:1 , to obtain 30ml of sodium fusidate solution; control the temperature at 25°C, add ethyl acetate solution under stirring state, when the flow rate is 510ml, after the addition is completed, stir for 1h, filter with suction, and place the filter cake at 40°C After drying for 42 hours, 8.7 g of sodium fusidate crystals were obtained. After testing its X-ray powder diffraction pattern is as follows figure 1 shown. As determined by HPLC, its purity was 99.98%. The yield was 92.72%.

Embodiment 3

[0031] Weigh 9.0 g of fusidic acid solids, dissolve and clarify it with absolute ethanol at 35° C., and add 4 M aqueous sodium hydroxide solution under stirring. The molar ratio of added sodium hydroxide to fusidic acid is 1.2:1, to obtain 35ml of sodium fusidate solution; control the temperature at 40°C, add ethyl acetate solution under stirring, the flow rate is 35ml / h, when the amount of ethyl acetate is 700ml, stop feeding, Stir again for 1.5h, filter with suction, place the filter cake at 45°C and dry for 48h to obtain 8.5g of sodium fusidate crystals, whose X-ray powder diffraction pattern is as follows: figure 1 shown. As determined by HPLC, the purity was 99.89%, and the yield was 90.59%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com