Colorful smart dimming polyvinyl butyral film and preparation method of laminated glass thereof

The technology of polyvinyl butyral film and polyvinyl butyral is applied in the field of preparation of color intelligent dimming polyvinyl butyral film and laminated glass, which can solve the problem of being unsuitable for mass production and expensive equipment. , complex process and other problems, to achieve the effect of reducing the possibility of oxidation and man-made damage, improving stability and life, and simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 0.5g of undoped vanadium dioxide powder; VO 2 The particle size is 100nm;

[0027] (2) Prepare 0.5% vanadium dioxide dispersion with ethanol;

[0028] (3) Add the vanadium dioxide dispersion to a certain amount of PVB resin, and stir to form a PVB slurry with a vanadium dioxide content of 1g / L;

[0029] (4) The PVB slurry is extruded and then cast and drawn to obtain an intelligent dimming PVB film.

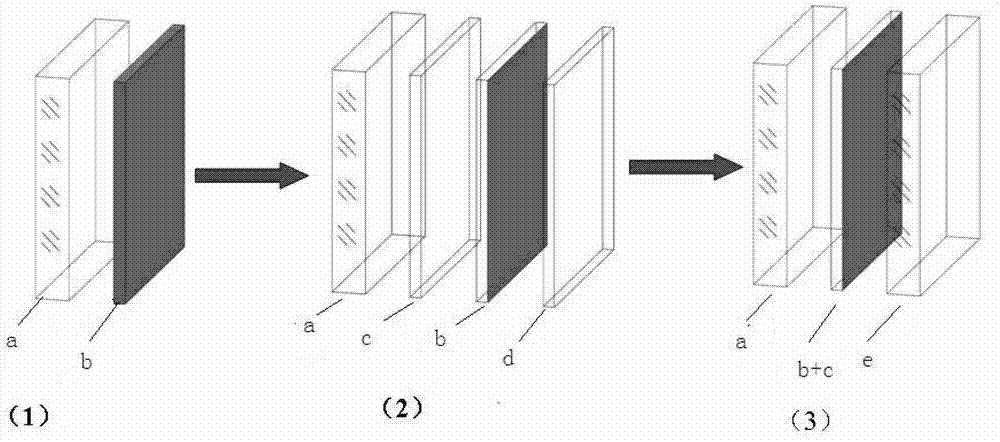

[0030] (5) The smart dimming PVB film and the color PVB film are laminated and sandwiched between two pieces of ordinary glass, and the color smart dimming PVB laminated glass is obtained by hot pressing.

Embodiment 2

[0032] (1) Take 0.5g of vanadium dioxide powder with 0.5% tungsten molar content; VO 2 The particle size is 20nm;

[0033] (2) Prepare a vanadium dioxide dispersion with a mass percentage of 1% with acetone;

[0034] (3) put VO 2 The dispersion liquid is added to PVB resin, and VO is formed after stirring 2 PVB slurry with a content of 10g / L;

[0035] (4) The PVB slurry is extruded and then cast and drawn to obtain an intelligent dimming PVB film.

[0036] (5) The smart dimming PVB film and the color PVB film are laminated and sandwiched between two pieces of tempered glass, and the color smart dimming PVB laminated glass is obtained by hot pressing.

Embodiment 3

[0038] (1) Take 0.5g of vanadium dioxide powder with 1% tungsten molar content; VO 2 The particle size is 50nm;

[0039] (2) Use xylene to prepare a vanadium dioxide dispersion with a mass fraction of 2%;

[0040] (3) put VO 2 The dispersion liquid is added to PVB resin, and VO is formed after stirring 2 PVB slurry with a content of 15g / L;

[0041] (4) The PVB slurry is extruded and then cast and drawn to obtain an intelligent dimming PVB film.

[0042] (5) The smart dimming PVB film and the color PVB film are laminated and sandwiched between two pieces of ordinary glass, and the color smart dimming PVB laminated glass is obtained by hot pressing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com