Modification method for inorganic fibers

A technology of inorganic fiber modification, applied in the field of fiber modification, can solve the problem of difficult wrapping of film-forming substances, achieve the effect of improving softness and strength, and improving paper performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

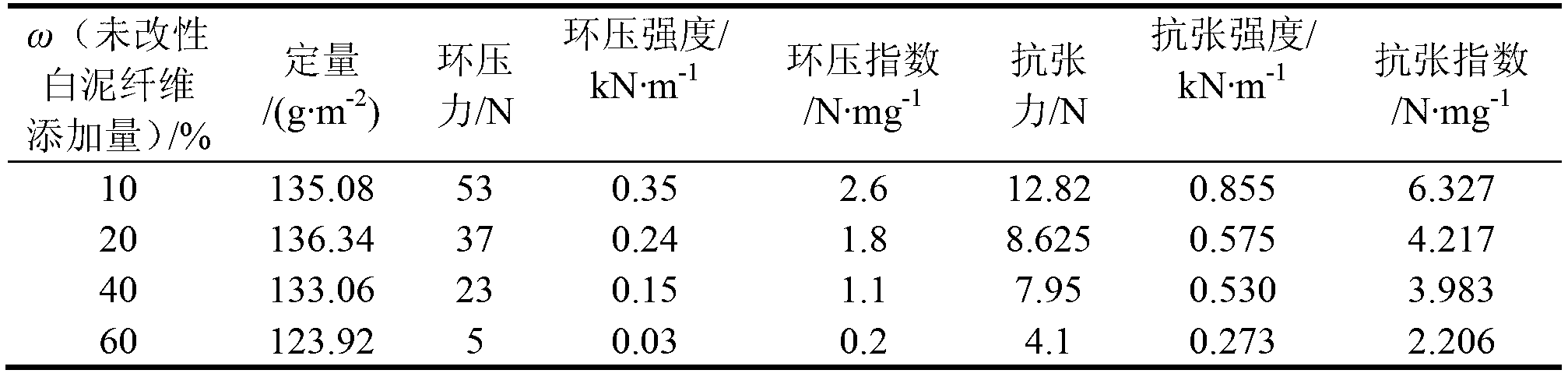

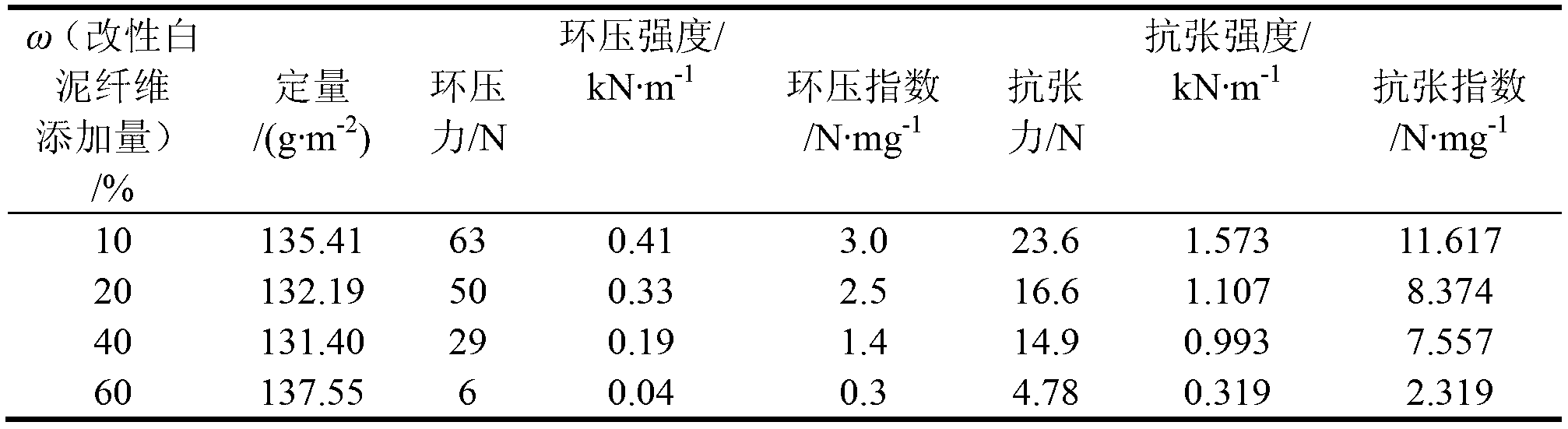

Examples

Embodiment 1

[0018] 1) Mix polyvinyl alcohol and water according to the mass ratio of 1:9, and stir and heat to 85°C until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solution, and then add sodium hydroxide and mass concentration to the polyvinyl alcohol aqueous solution It is 30% hydrogen peroxide, reacted at 85°C for 4 hours to obtain treated polyvinyl alcohol; wherein, the mass ratio of hydrogen peroxide to polyvinyl alcohol aqueous solution was 1:150, and the mass of sodium hydroxide added was hydrogen peroxide 4% of mass;

[0019] 2) Mix the treated polyvinyl alcohol with γ-glycidyl etheroxypropyl trimethoxysilane at a mass ratio of 1:0.4, then react at 90°C for 30 minutes, and adjust the pH to 7 to obtain an inorganic fiber softening enhancer ;

[0020] 3) Add 2g of lime mud fiber to 100mL of water, stir to disperse the lime mud fiber, then add 5g of inorganic fiber softening and strengthening agent, stir well, and then add 5mL of cationic pol...

Embodiment 2

[0022] 1) Mix polyvinyl alcohol with water at a mass ratio of 1:8, stir and heat to 90°C until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solution, and then add sodium hydroxide and mass concentration to the polyvinyl alcohol aqueous solution It is 30% hydrogen peroxide, and reacted at 90°C for 4 hours to obtain treated polyvinyl alcohol; wherein, the mass ratio of hydrogen peroxide to polyvinyl alcohol aqueous solution is 1:100, and the mass of sodium hydroxide added is hydrogen peroxide 5% of the mass;

[0023] 2) Mix the treated polyvinyl alcohol with γ-glycidyl etheroxypropyl trimethoxysilane at a mass ratio of 1:0.7, then react at 110°C for 30 minutes, and adjust pH=8 to obtain an inorganic fiber softening enhancer ;

[0024] 3) Add 2g of lime mud fiber to 150mL of water, stir to disperse the lime mud fiber, then add 7g of inorganic fiber softening and strengthening agent, stir well, and then add 7mL of cationic polyacrylamide sol...

Embodiment 3

[0026] 1) Mix polyvinyl alcohol and water according to the mass ratio of 1:11, and stir and heat to 80°C until the polyvinyl alcohol is completely dissolved to obtain a polyvinyl alcohol aqueous solution, and then add sodium hydroxide and mass concentration to the polyvinyl alcohol aqueous solution It is 30% hydrogen peroxide, and reacted at 80°C for 4 hours to obtain treated polyvinyl alcohol; wherein, the mass ratio of hydrogen peroxide to polyvinyl alcohol aqueous solution is 1:200, and the mass of sodium hydroxide added is hydrogen peroxide 7% of mass;

[0027] 2) Mix the treated polyvinyl alcohol with γ-glycidyl etheroxypropyl trimethoxysilane at a mass ratio of 1:0.6, then react at 100°C for 30 minutes, and adjust the pH to 9 to obtain an inorganic fiber softening enhancer ;

[0028] 3) Add 2g of lime mud fiber to 200mL of water, stir to disperse the lime mud fiber, then add 10g of inorganic fiber softening and strengthening agent, stir well, and then add 3mL of cationi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com