Method and system for preparing high-purity hydrogen chloride

一种氯化氢、高纯度的技术,应用在氯/氯化氢、氯化氢制备、有机化学方法等方向,能够解决难操作等问题,达到能量消耗降低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

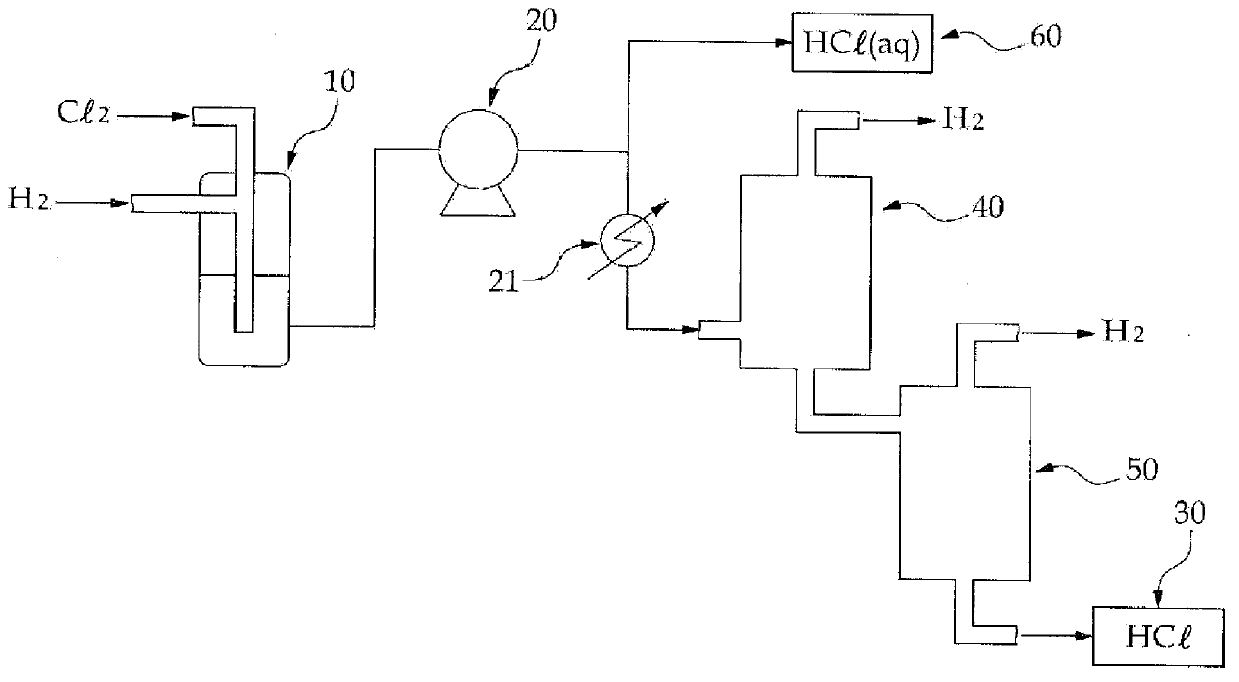

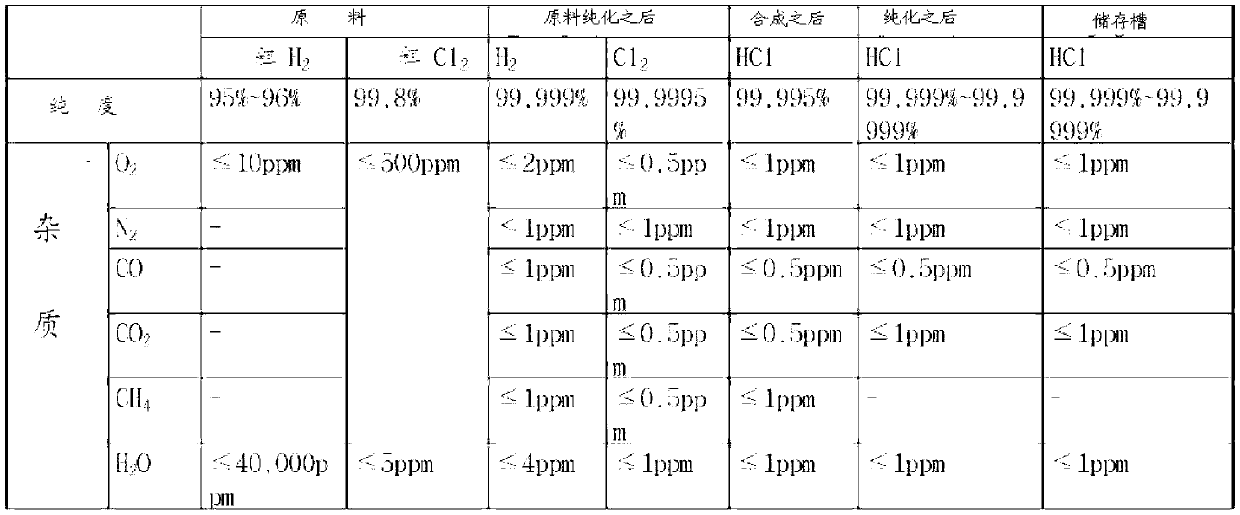

[0044] In an embodiment of the present invention, a system for producing high-purity hydrogen chloride is used, comprising: a reactor 10 for reacting purified high-purity hydrogen with purified high-purity chlorine; A compressor 20 for hydrogen chloride gas; a cooler 21 for hydrogen chloride passing through the compressor; a hydrochloric acid storage tank 60 for dissolving hydrogen chloride passing through the compressor in deionized water to prepare high-purity hydrochloric acid and storing the prepared hydrochloric acid ; a two-stage distillation column (ie, a first distillation column 40 and a second distillation column 50 ) for fractionating hydrogen chloride liquefied in a compressor to remove unreacted hydrogen and the like; and for storage in the distillation column Hydrogen chloride storage tank 30 for purified hydrogen chloride. Using this hydrogen chloride production system, hydrogen chloride is produced. Specifically, hydrogen and chlorine are respectively about 80...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com