Application of acethydrazide type compound containing furan nitrogen heterocycle and being used as corrosion inhibitor

A compound, the technology of acetylhydrazine, which is applied in the field of application of acetylhydrazide compounds as corrosion inhibitors, can solve the problems of loss of thermal, electrical and mechanical properties, few reports on technology and product quantity, corrosion damage, etc., and achieve excellent corrosion inhibition Performance, excellent durability, effect of suppressing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

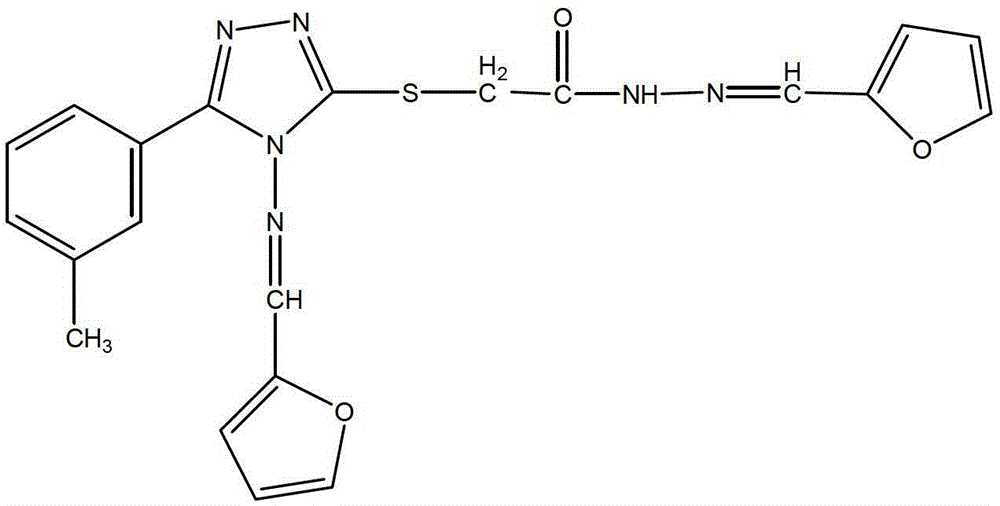

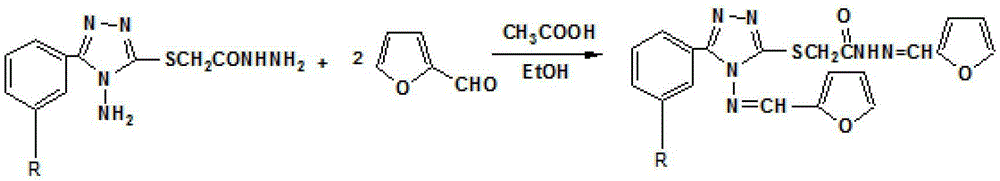

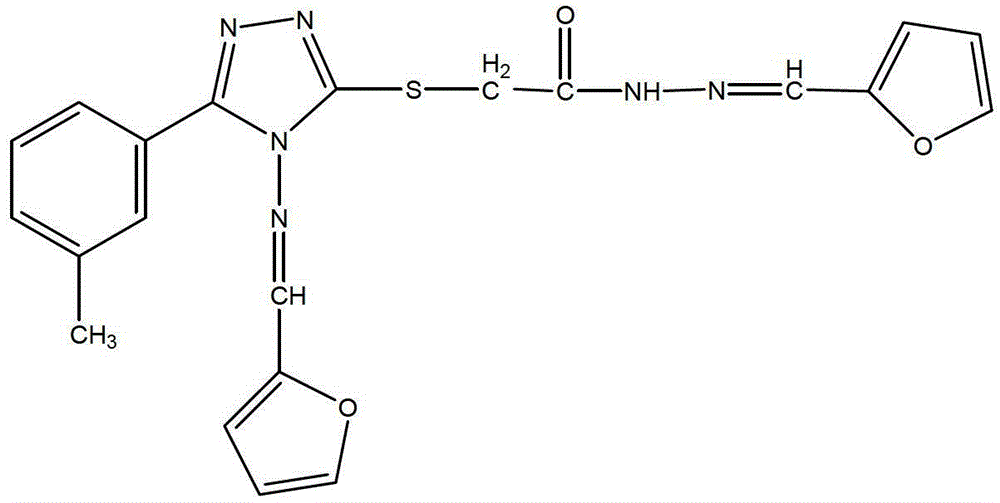

Image

Examples

Embodiment 1

[0030] The experimental material is red copper (99.999%). The compound of formula 1 is formulated as a corrosion inhibitor. The medium is 3.5% sodium chloride solution. The red copper product is immersed in the medium with the corrosion inhibitor at a temperature of 25°C and a pH of 7.5. The amount of medium used is 100L, the amount of the compound of formula 1 in the medium is 0.01g, the temperature is 25°C, pH=7.0, and the immersion time is 20 days.

[0031] The corrosion inhibitor is: dissolve the compound of formula one in ethanol, and its weight ratio to ethanol is 1:10, and then use an ultrasonic disperser to ultrasonically disperse the mixed solution for 20 minutes at room temperature to completely dissolve it; then, put The fully dissolved solution was added to the OP-10 emulsifier (C 34 h 62 o 11 ) (Tianjin Damao Chemical Instrument Supply Station), the weight ratio of OP-10 emulsifier to ethanol is 1:1, and stirred at room temperature until a uniform microemulsion ...

Embodiment 2

[0034] The experimental material is red copper (99.999%). The compound of formula 1 is formulated as a corrosion inhibitor. The medium is 3.5% sodium chloride solution. The red copper product is immersed in the medium with the corrosion inhibitor at a temperature of 25°C and a pH of 7.5. The amount of medium used is 100L, the amount of the compound of formula 1 in the medium is 0.1g, the temperature is 25°C, pH=7.0, and the immersion time is 20 days.

[0035] The corrosion inhibitor is: dissolve the compound of formula one in ethanol, and its weight ratio to ethanol is 1:10, and then use an ultrasonic disperser to ultrasonically disperse the mixed solution for 20 minutes at room temperature to completely dissolve it; then, put The fully dissolved solution was added to the OP-10 emulsifier (C 34 h 62 o 11 ) (Tianjin Damao Chemical Instrument Supply Station), the weight ratio of OP-10 emulsifier to ethanol is 1:1, and stirred at room temperature until a uniform microemulsion a...

Embodiment 3

[0038] The experimental material is red copper (99.999%). The compound of formula 1 is formulated as a corrosion inhibitor. The medium is 3.5% sodium chloride solution. The red copper product is immersed in the medium with the corrosion inhibitor at a temperature of 25°C and a pH of 7.5. The amount of medium used is 100L, the amount of the compound of formula 1 in the medium is 0.5g, the temperature is 25°C, pH=7.0, and the immersion time is 20 days.

[0039] The corrosion inhibitor is: dissolve the compound of formula one in ethanol, and its weight ratio to ethanol is 1:10, and then use an ultrasonic disperser to ultrasonically disperse the mixed solution for 20 minutes at room temperature to completely dissolve it; then, put The fully dissolved solution was added to the OP-10 emulsifier (C34 h 62 o 11 ) (Tianjin Damao Chemical Instrument Supply Station), the weight ratio of OP-10 emulsifier to ethanol is 1:1, and stirred at room temperature until a uniform microemulsion app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com