Electro-hydraulic compound braking system based on hydraulic control unit and integrated braking master cylinder

A control unit, brake master cylinder technology, applied in the direction of brake transmission, brake, transportation and packaging, etc., can solve the problems of high manufacturing process requirements, complex control logic, high implementation cost, etc., to achieve scalability and applicability Good, the production process is simple, and the effect of improving braking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

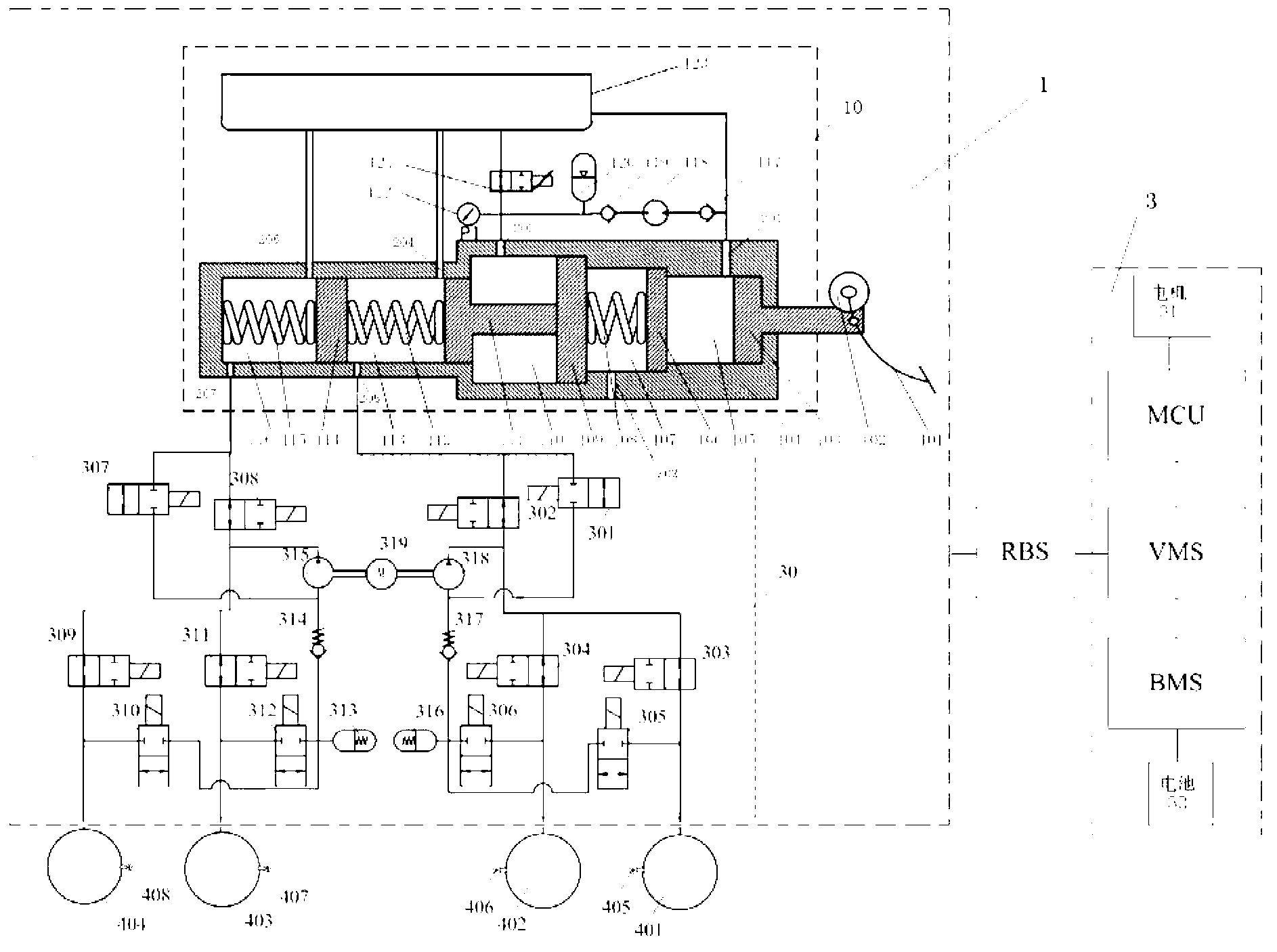

[0037] Such as figure 1 As shown, an electro-hydraulic hybrid braking system based on a hydraulic control unit and an integrated brake master cylinder includes a hydraulic brake subsystem 1, and the hydraulic brake subsystem 1 is composed of an integrated brake master cylinder assembly 10 Composed of a hydraulic control unit 30, the electro-hydraulic composite braking system also includes a composite braking control unit RBS and a motor feedback braking subsystem 3, the hydraulic braking subsystem 1, the composite braking control unit RBS and The motor regenerative braking subsystem 3 is connected sequentially, and the motor regenerative braking subsystem 3 is composed of a motor 31 , a motor controller MCU, a vehicle controller VMS, a battery management system BMS and a battery pack 32 .

[0038] Basic working principle: the composite brake control unit RBS collects the brake pedal displacement sensor 102 to obtain the driver's braking operation intention, and calculates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com