Device and process for preparing isobutylene by dehydrogenating isobutane

A technology of isobutene and isobutane, which is applied in the field of isobutane dehydrogenation to produce isobutene and product recovery, can solve environmental hazards and other problems, and achieve the effect of inhibiting coking reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

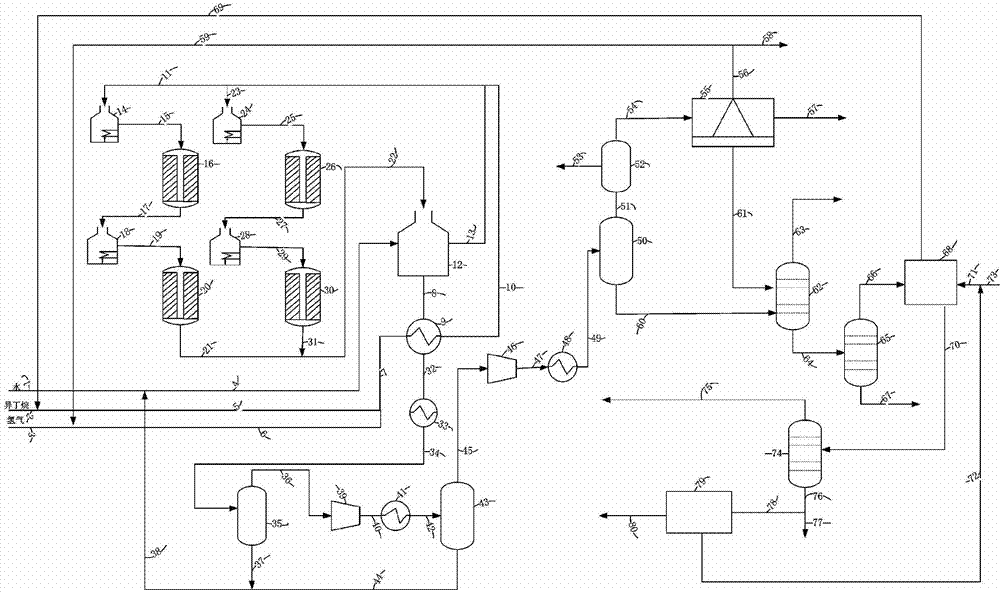

[0062] Raw material isobutane 2, diluent H 2 3 and H 2 O1 exchanges heat with the high-temperature stream from the dehydrogenation reactor through the cooling heat exchanger I9 and the steam generator 12, and then enters the heating furnace I14 to be heated to 610°C to obtain isobutane, H 2 and H 2 High temperature stream 15 of O mixture. Stream 15 enters the dehydrogenation reactor I16, set the pressure of the dehydrogenation reactor to 0.3MPa, and the gas space velocity to 2500h -1 , the reaction feed gas volume ratio is isobutane: hydrogen: water vapor = 1:0.5:1.5, under the action of the platinum series catalyst with Pt-Sn-K as the active component suggested by the patent CN102000593, part of the isobutane is removed Hydrogen forms isobutene. The stream coming out of the dehydrogenation reactor I16 enters the heating furnace II18 to heat the gas flow to 600°C and then enters the dehydrogenation reactor II20. The pressure of the dehydrogenation reactor II is set at 0.25...

Embodiment 2

[0072] Raw material isobutane 2, diluent H 2 3 and H 2 O1 exchanges heat with the high-temperature stream leaving the dehydrogenation reactor through the cooling heat exchanger I9 and the steam generator 12, and then enters the heating furnace I14 to be heated to 630°C to obtain isobutane, H 2 and H 2 High temperature stream 15 of O mixture. Stream 15 enters the dehydrogenation reactor I16, set the pressure of the dehydrogenation reactor to 0.5MPa, and the gas space velocity to 4000h -1 , the reaction feed gas volume ratio is isobutane: hydrogen: water vapor = 1:0.5:1.0, part of the isobutane is removed under the action of the platinum catalyst with Pt-Sn-K as the active component suggested by the patent CN102000593 Hydrogen forms isobutene. The stream coming out of the dehydrogenation reactor I16 enters the heating furnace II18 to heat the gas stream to 630°C and then enters the dehydrogenation reactor II20. The pressure of the dehydrogenation reactor II is set at 0.4 MPa...

Embodiment 3

[0082] Raw material isobutane 2, diluent H 2 3 and H 2 O1 exchanges heat with the high-temperature stream leaving the dehydrogenation reactor through the cooling heat exchanger I9 and the steam generator 12, and then enters the heating furnace I14 to be heated to 640°C to obtain isobutane, H 2 and H 2 High temperature stream 15 of O mixture. Stream 15 enters the dehydrogenation reactor I16, set the pressure of the dehydrogenation reactor to 0.35MPa, and the gas space velocity to 5000h-1 , the reaction feed gas volume ratio is isobutane: hydrogen: water vapor = 1:1:1, under the action of the platinum series catalyst with Pt-Sn-K as the active component suggested by patent CN102000593, part of the isobutane is removed Hydrogen forms isobutene. The stream coming out of the dehydrogenation reactor I16 enters the heating furnace II18 to heat the gas stream to 650°C and then enters the dehydrogenation reactor II20. The pressure of the dehydrogenation reactor II is set to 0.3 MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com