Dual-component wetting and single-component curing-type antifreezing dust suppressant for coal transportation and storage

A dust suppressant, curing technology, applied in other chemical processes, chemical instruments and methods, etc., to achieve the effect of low cost, environmental protection, better antifreeze and dust suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

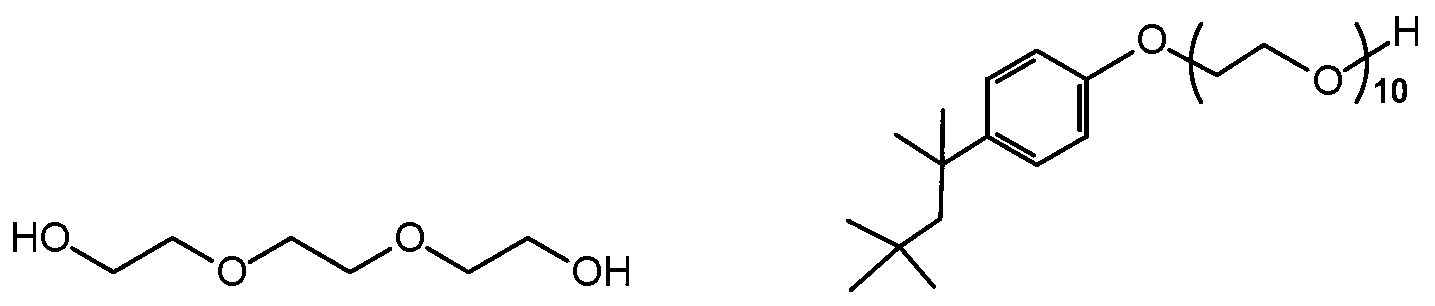

Embodiment 1

[0026] Dissolve 0.5 g of triethylene glycol and 0.5 g of Triton X-100 in 100 ml of water to prepare a wetting dust suppressant. Dissolve 0.5 g of magnesium hexafluorosilicate in 1000 ml of water to prepare a solidified dust suppressant. Take 2 kg of 10-30 mesh coal and spray it with 100 ml of wet dust suppressant. Then, spread it on a tray of 30 cm x 21 cm x 3 cm, and spray 100 ml of solidified dust suppressant. Test performance according to TB / T3210.1-2009 railway coal transportation dust suppression technical conditions. Dry at 50°C for 2 hours, then put it into a 30 m / s wind tunnel for 5 minutes, weigh the remaining coal weight, and the wind erosion rate is less than 10 mm. Place the above-mentioned tray in a -40°C refrigerator for 2 hours, and the coal can be dumped after taking it out, which can be considered to have achieved the antifreeze effect.

Embodiment 2

[0028] Dissolve 1.0 g of triethylene glycol and 1.0 g of Triton X-100 in 100 ml of water to prepare a wetting dust suppressant. Dissolve 1.0 g of magnesium hexafluorosilicate in 1000 ml of water to prepare a solidified dust suppressant. Take 2 kg of 10-30 mesh coal and spray it with 100 ml of wet dust suppressant. Then, spread it on a tray of 30 cm x 21 cm x 3 cm, and spray 100 ml of solidified dust suppressant. Test performance according to TB / T3210.1-2009 railway coal transportation dust suppression technical conditions. Dry at 50°C for 2 hours, then put it into a 30 m / s wind tunnel for 5 minutes, weigh the remaining coal weight, and the wind erosion rate is less than 10 mm. Place the above-mentioned tray in a -40°C refrigerator for 2 hours, and the coal can be dumped after taking it out, which can be considered to have achieved the antifreeze effect.

Embodiment 3

[0030] Dissolve 1.5 grams of triethylene glycol and 1.5 grams of Triton X-100 in 100 milliliters of water to prepare a wetting dust suppressant. Dissolve 1.5 grams of magnesium hexafluorosilicate in 1000 milliliters of water to prepare a solidified dust suppressant. Take 2 kg of 10-30 mesh coal and spray it with 100 ml of wetting dust suppressant. Then, spread it on a tray of 30 cm x 21 cm x 3 cm, and spray 100 ml of solidified dust suppressant. Test performance according to TB / T3210.1-2009 railway coal transportation dust suppression technical conditions. Dry at 50°C for 2 hours, then put it into a 30 m / s wind tunnel for 5 minutes, weigh the remaining coal weight, and the wind erosion rate is less than 10 mm. Place the above-mentioned tray in a -40°C refrigerator for 2 hours, and the coal can be dumped after taking it out, which can be considered to have achieved the antifreeze effect.

[0031] Tests have shown that the reduction of high and low calorific value of coal is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com