Electroplating solution and application thereof

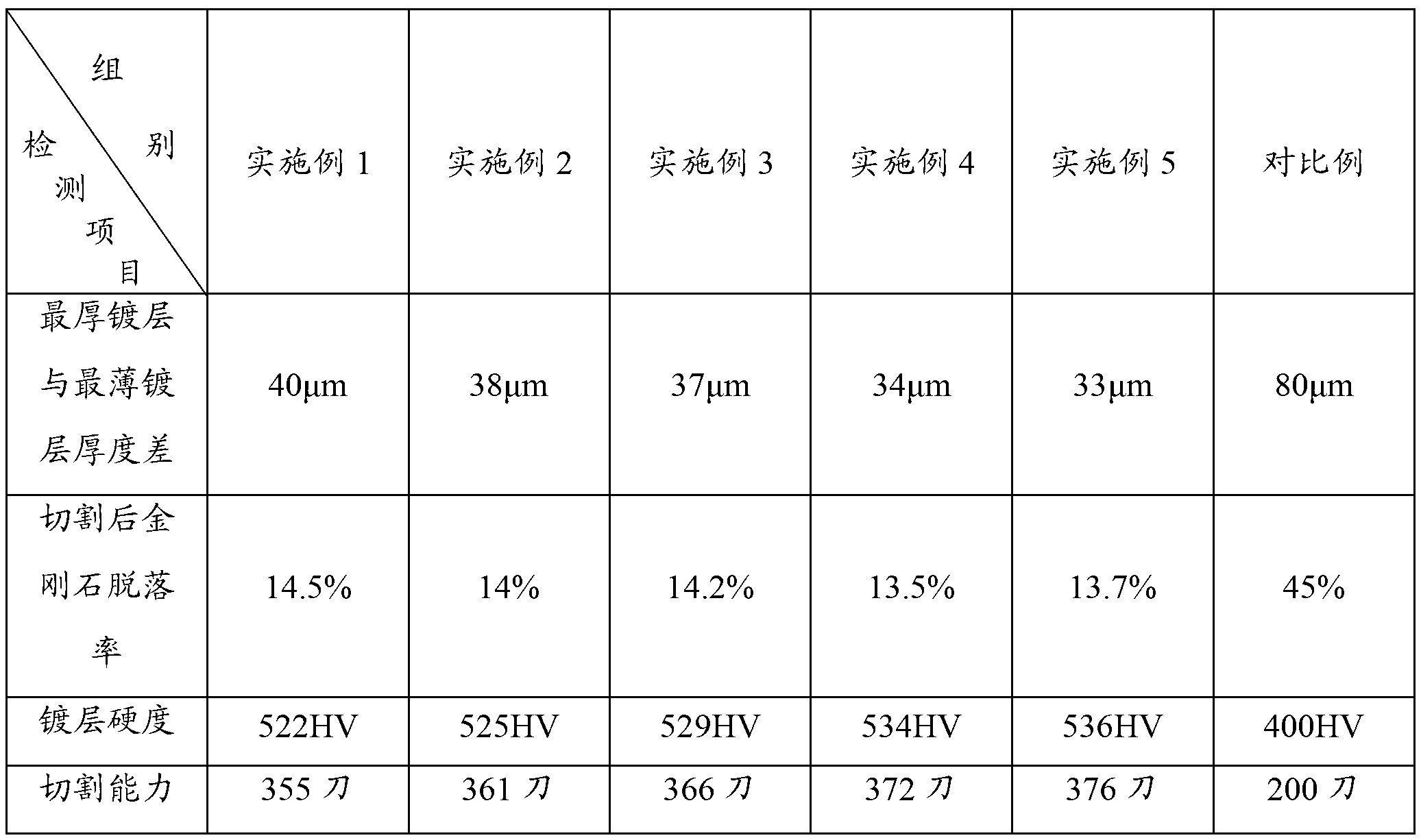

A technology of electroplating solution and solute, applied in the direction of electrolytic paint, coating, etc., can solve the problems of uneven thickness of metal coating and easy falling off of diamond, and achieve the effect of improving cutting efficiency and cutting ability, reducing coating thickness and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

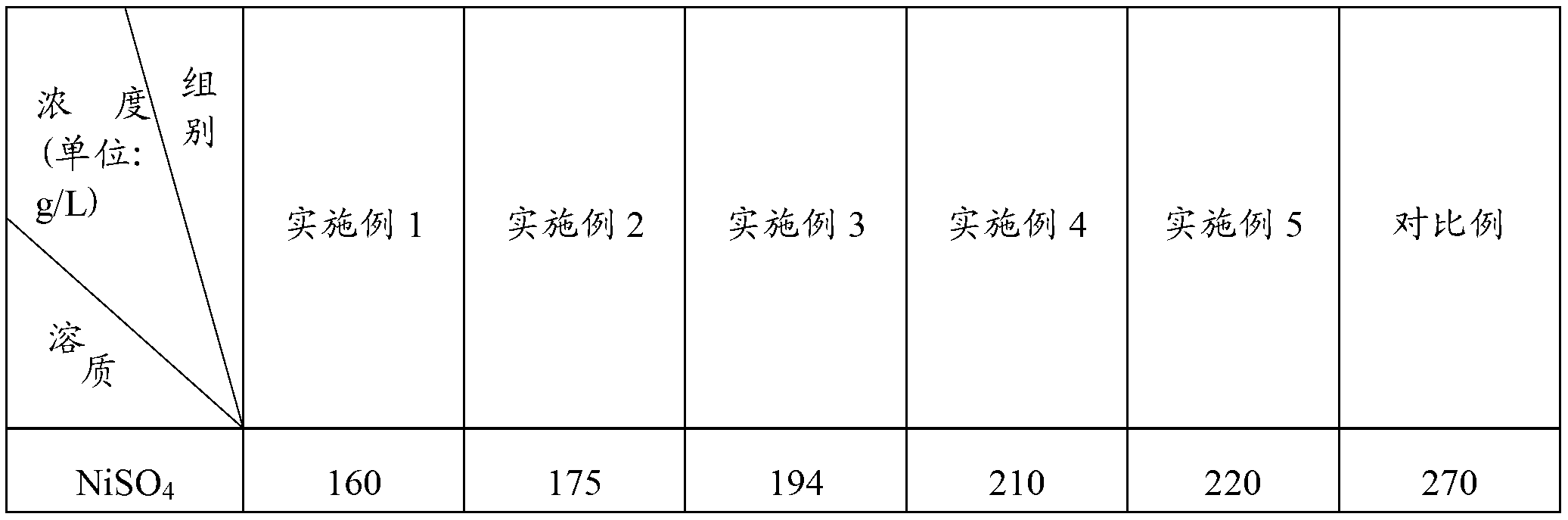

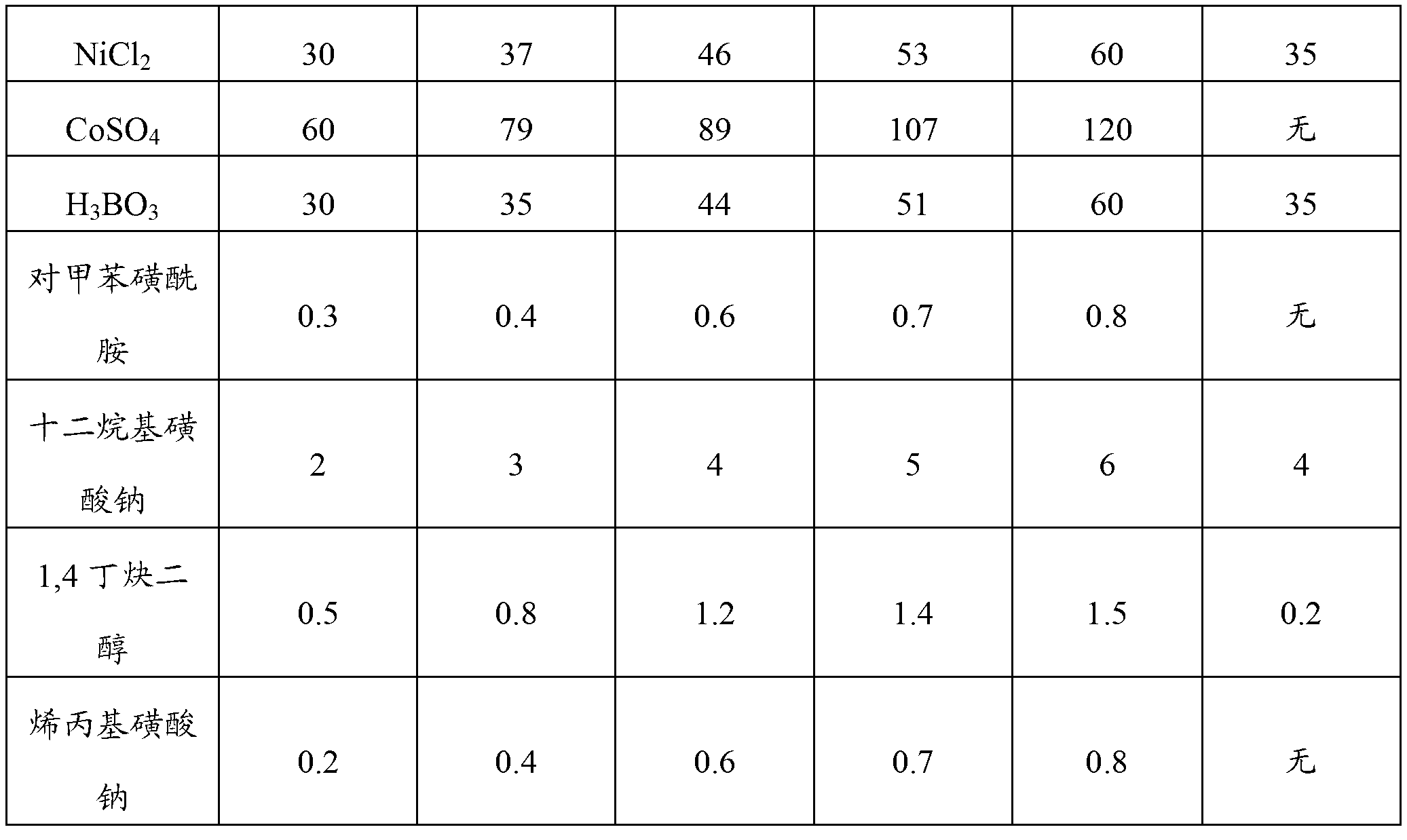

[0062] The electroplating solution and its application will be described in further detail below mainly in conjunction with specific examples.

[0063] The electroplating solution of one embodiment of the present invention is mainly used in the diamond saw band electroplating process, and its solvent is water, and solute and solute concentration are as follows:

[0064] Nickel Sulfate (NiSO 4 ) 160~220g / L;

[0065] Nickel Chloride (NiCl 2 ) 30~60g / L;

[0066] Cobalt Sulfate (CoSO 4 ) 60~120g / L;

[0067] boric acid (H 3 BO 3 ) 30~60g / L;

[0068] p-toluenesulfonamide (PTSA) 0.3~0.8g / L;

[0069] Sodium dodecylsulfonate (SDS) 2~6g / L;

[0070]1,4 butynediol (MSDS) 0.5~1.5g / L; and

[0071] Sodium allyl sulfonate (the structural formula is CH 2 =CH-CH 2 -SO 3 Na)

[0072] 0.2~0.8g / L.

[0073] Further, in a preferred embodiment, each solute and concentration of the electroplating solution are respectively:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com