Backstepping control method of pneumatic position servo system

A servo system, pneumatic position technology, applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem of insufficient tracking control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

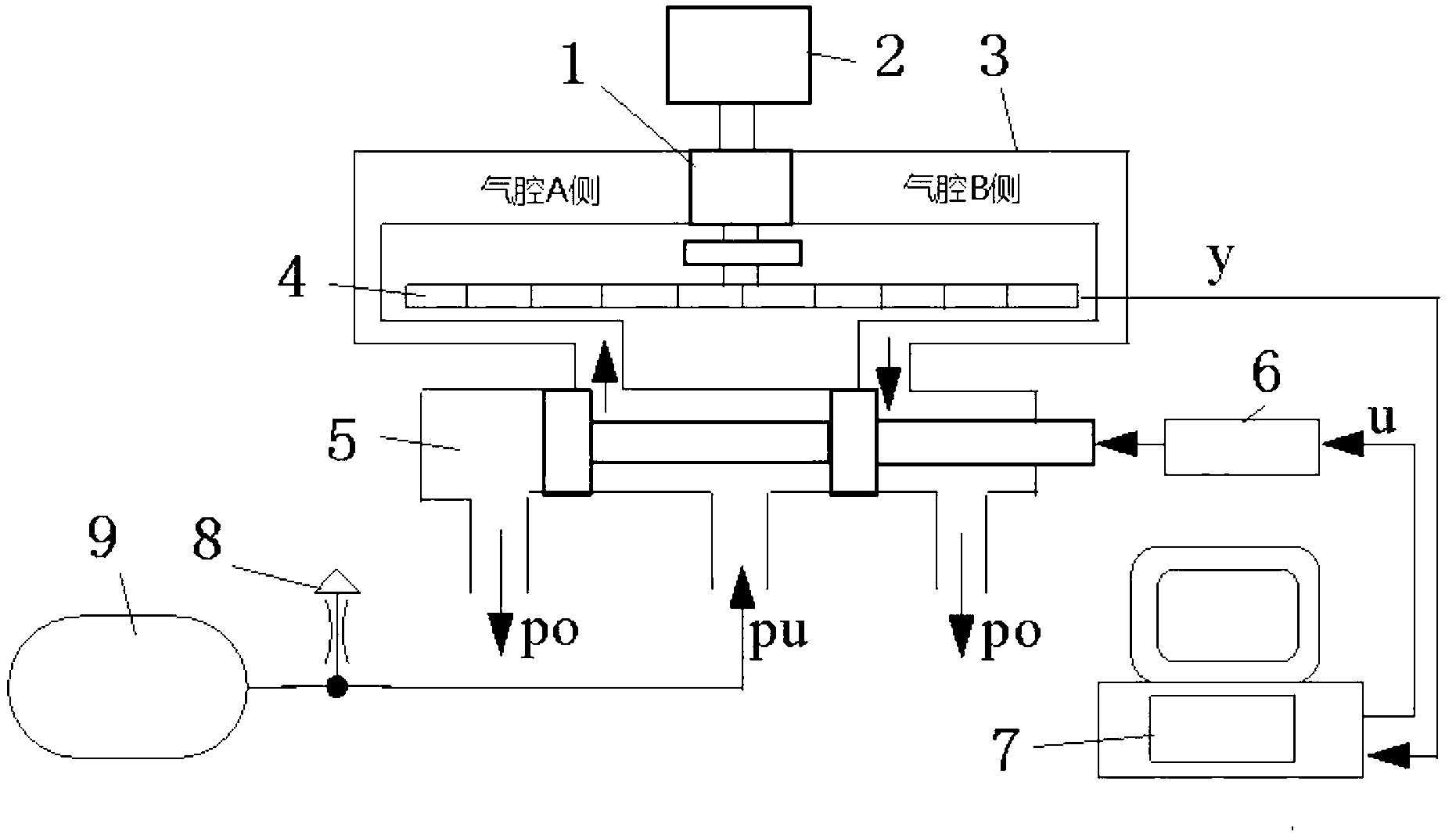

[0060] Each component in the structure of the pneumatic position servo system is selected separately: the rodless cylinder of FESTO company (the model used is DGPL-25-450-PPV-A-B-KF-GK-SV); the five-way proportional valve (the model used is MPYE -5-1 / 8-HF-010-B); sliding resistance linear displacement detector (the model used is MLO-POT-450-TLF, and the position detection accuracy is 0.15mm after matching with the acquisition card); computer (the model used is The model is CPU (P21.2GHz); general data acquisition card (the model used is PCI2306); air pump and other components constitute the pneumatic position servo system. The built-in control software of the computer is compiled by VB, and the change curve of related variables in the control process is displayed on the screen.

[0061] The control targets are set to

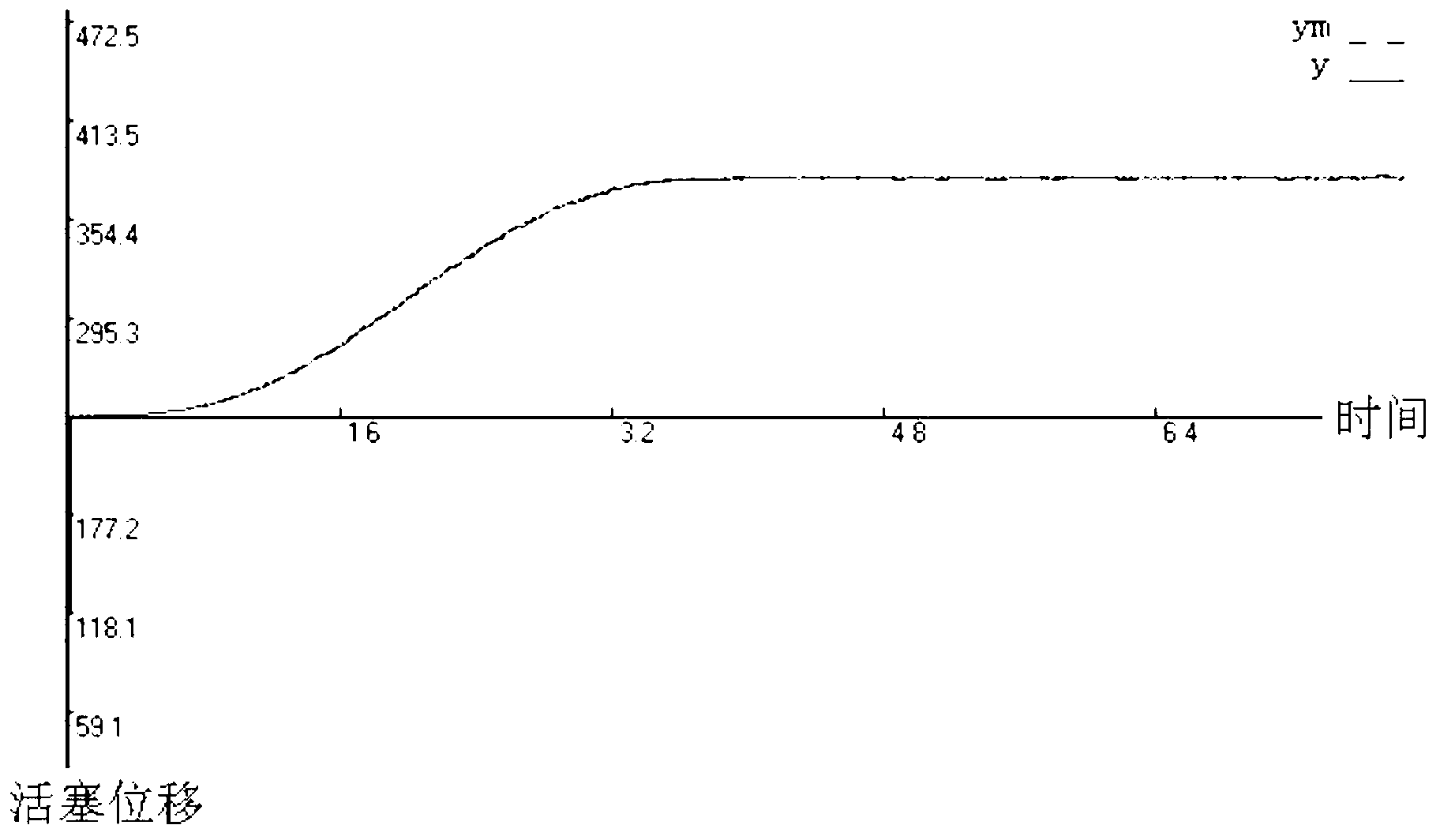

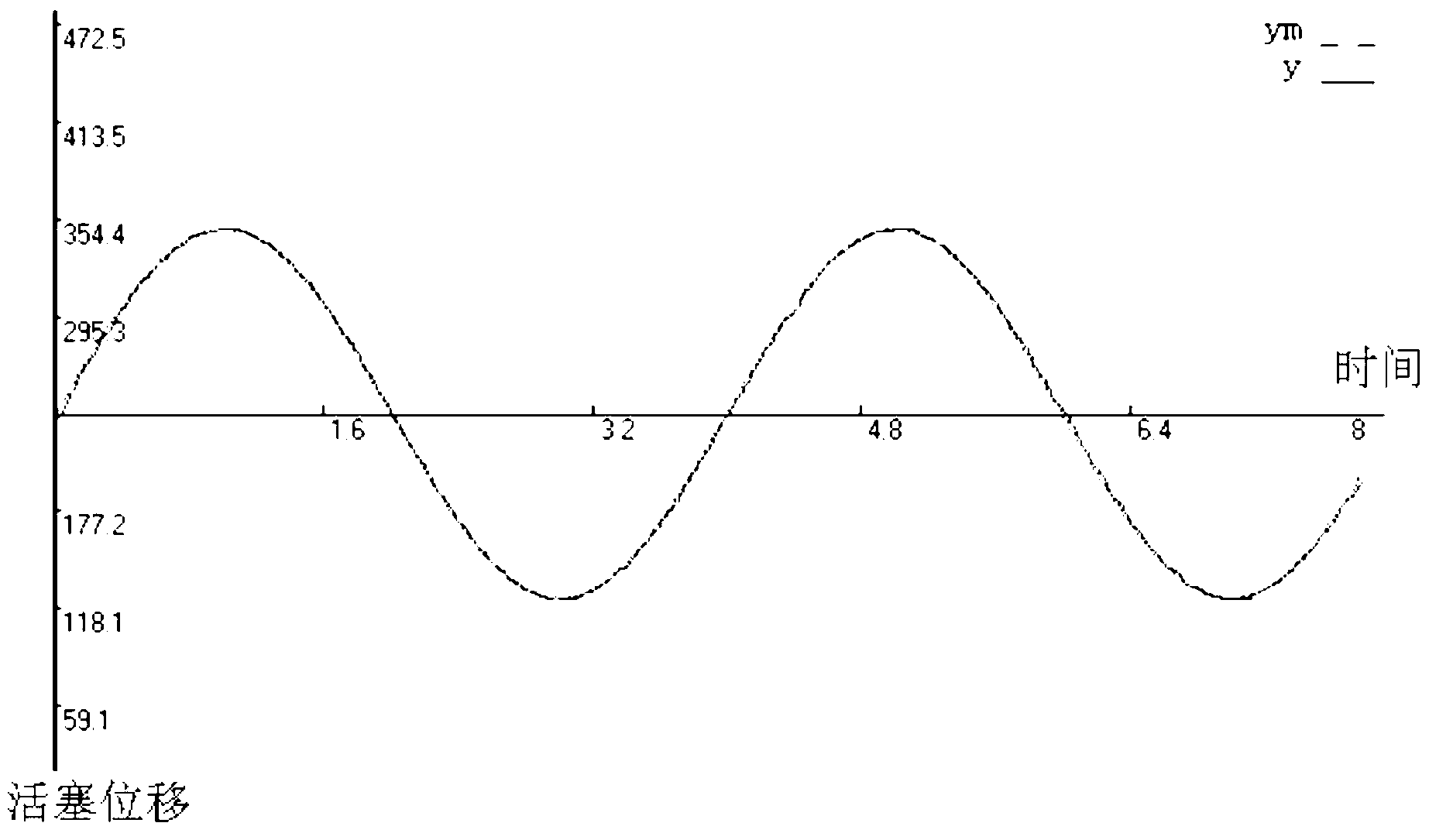

[0062] Reference signal 1: S-curve

[0063] the y d =-(A / ω 2 )sin(ωt)+(A / ω)t, (7)

[0064] The value of A is 55.825, and the value of w is 0.5π.

[0065] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com