Method for preparing reduced graphene oxide-based flexible transparent conductive thin film

A technology of transparent conductive film and graphene film, which is applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of hydrazine being highly toxic and reducing electron transmission efficiency, and achieve low cost, abundant raw materials, and green preparation process The effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0044] Example: Preparation method of flexible transparent reduced graphene oxide conductive film.

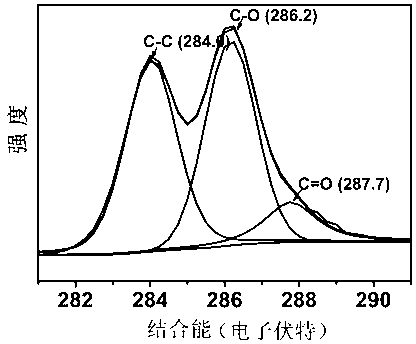

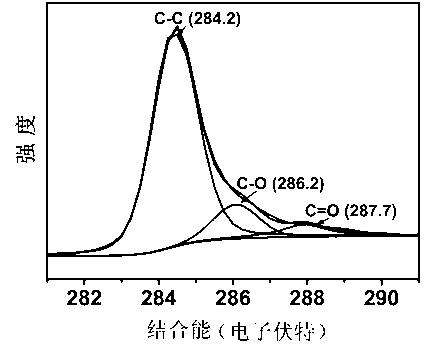

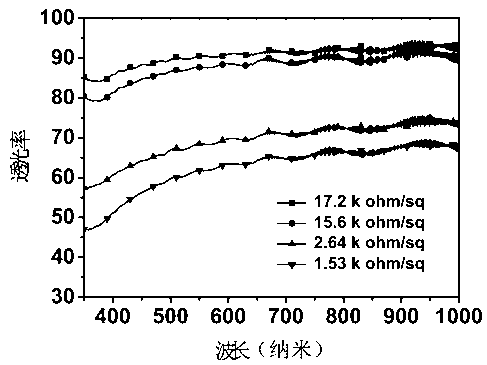

[0045] Preparation and reduction of graphene oxide film: First, the aqueous phase suspension (3 mg / mL) of large sheets of graphene oxide was ultrasonicated for 20 min by a powerful oscillating ultrasonic machine to obtain a dispersed and stable solution. In order to highlight the influence of graphene oxide size on conductivity, graphene oxide aqueous solutions of different sizes were prepared: the solution was divided into three parts, and one part was reserved (the area of graphene oxide was 1000-1200 μm 2 ), take the remaining two solutions and use a probe ultrasonic machine to sonicate for 10 min and 20 min respectively, aiming to obtain solutions of graphene oxide with different sizes (the area of graphene oxide is 100-200 μm for 10 min of probe sonication 2 ; Probe ultrasonic 20 min graphene oxide area is 10-20 μm 2 ). Secondly, the PET substrate was treated by plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com