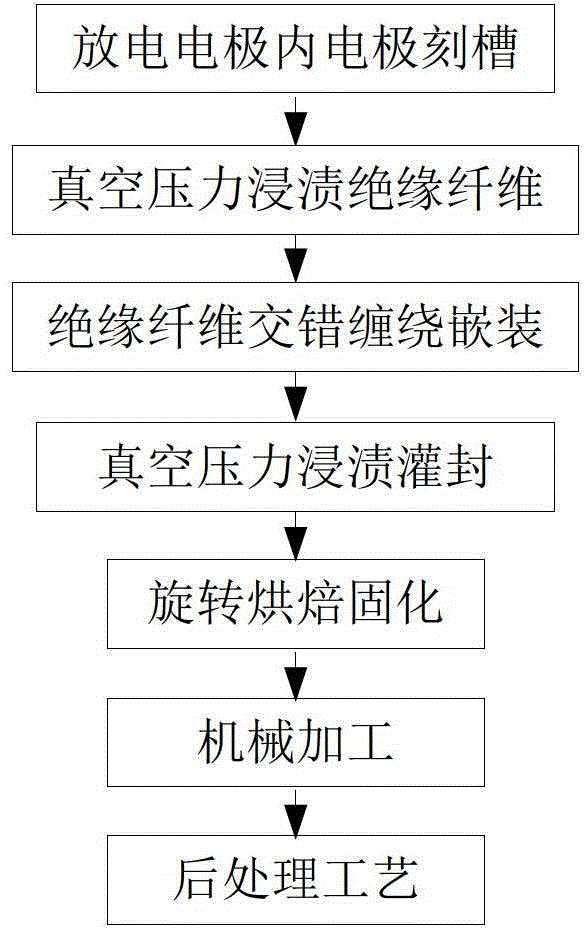

Preparation method of discharge electrode high-strength insulation structure

An insulating structure and discharge electrode technology, which is applied to electrical components, sounding equipment, instruments, etc., can solve the problems of inability to adapt to high-power and high-current underwater pulse discharge, unable to update the central copper rod, and the insulation structure is no longer reliable. Avoid the effects of rapid aging, small loss, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Describe the present invention below in conjunction with specific embodiment:

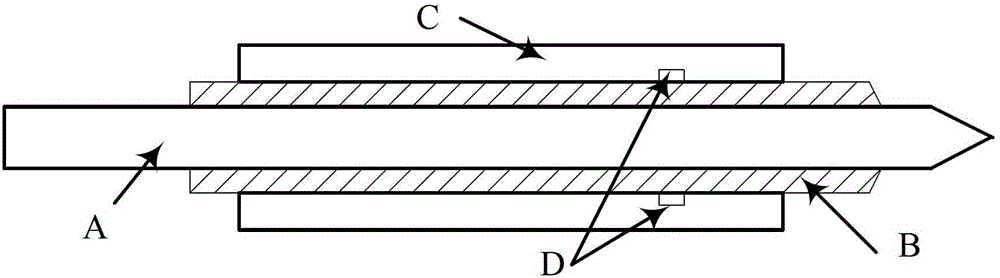

[0024] Refer to attached figure 1 , the high-strength insulating structure of the underwater plasma sound source discharge electrode in the present embodiment comprises an inner electrode A and an insulating layer B, and the inner electrode A and the insulating layer B are processed into an integrated insulating structure with high insulating strength and mechanical strength; The outer surface of layer B is a thread structure, which is coaxially sealed with the inner thread of the outer electrode C, and can rotate relative to each other; the inner surface of the outer electrode C is a thread structure, and has a watertight groove and a watertight ring D.

[0025] The requirements for the use of underwater plasma sound sources in this embodiment refer to discharge electrodes under the conditions of high voltage (5kV-50kV), high repetition frequency (greater than 1Hz), and high energy (100-500...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com