Product discharging, liquid supplying and cleaning device for automatic cooking device and operation method thereof

A cleaning device and automatic cooking technology, which is applied to the processing of finished cooking products or liquid discharge, the output of automatic cooking equipment, liquid supply and cleaning devices, which can solve the hidden dangers of oil safety, single function, weak function scalability, etc. problems, to achieve reliable cleaning and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

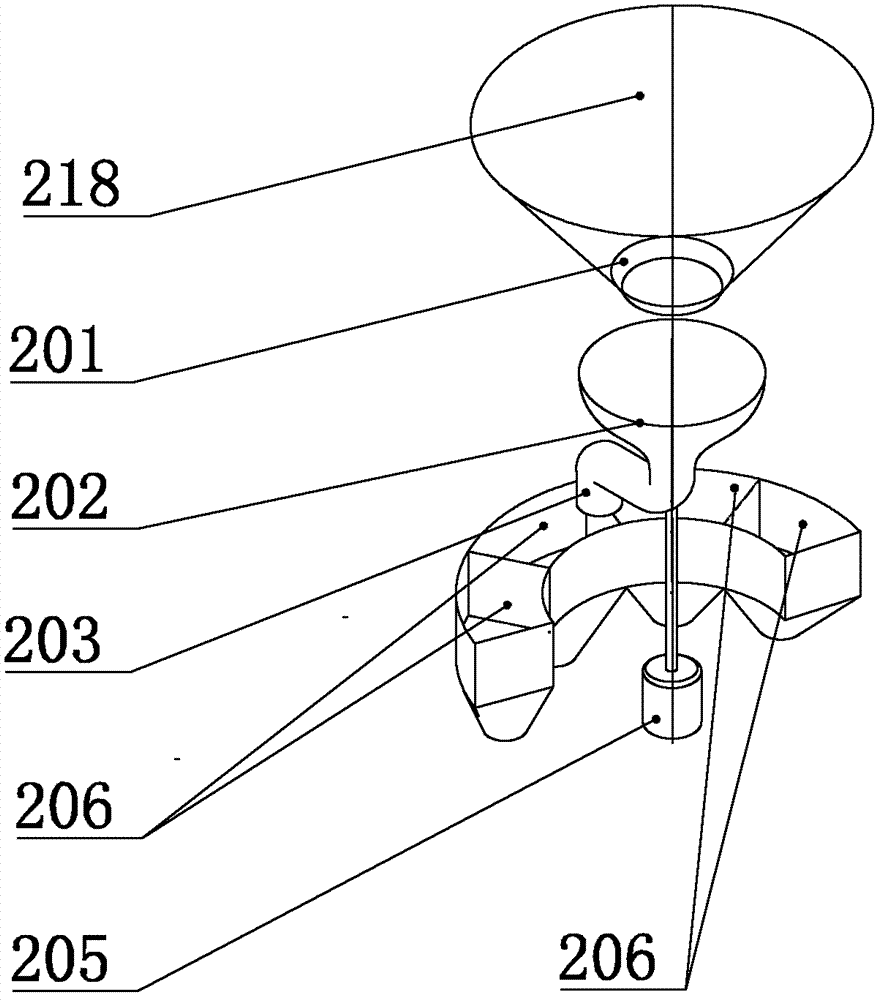

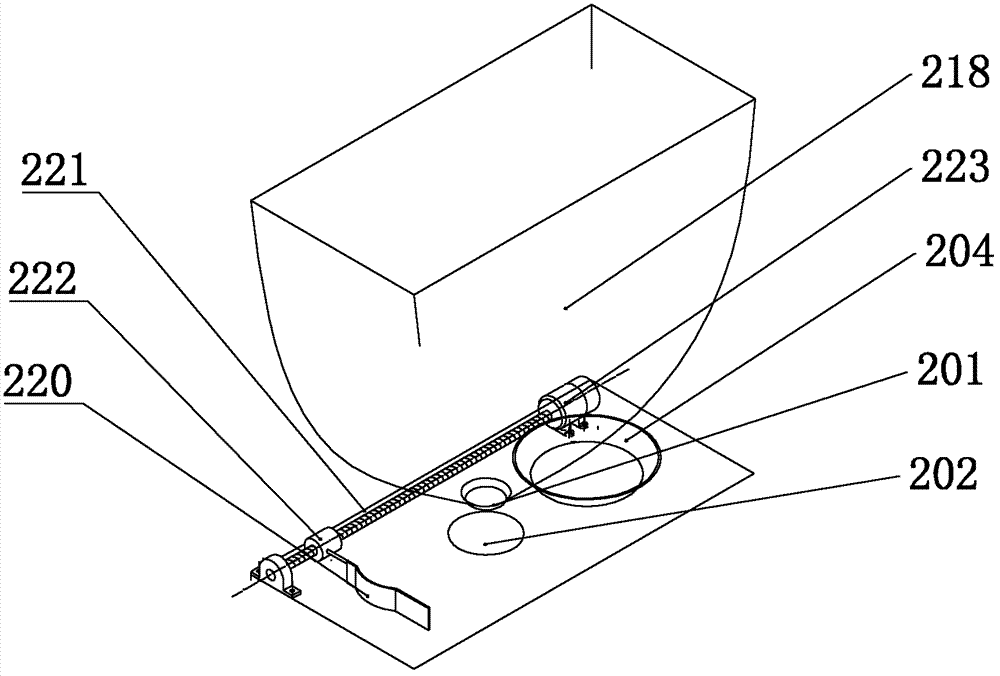

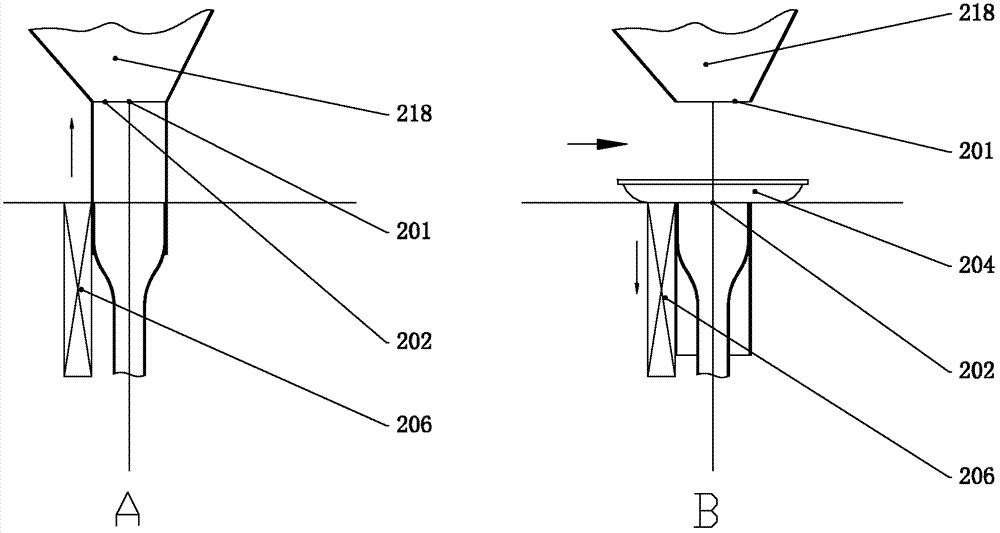

[0056] figure 1 A schematic structural view showing a liquid receiving and distributing device used in a material discharging, liquid supplying and cleaning device of automatic cooking equipment according to one aspect of the present invention. refer to figure 1 , the automatic cooking equipment includes a discharge port 201, through which the cooked products or liquid discharges (such as cooking liquid, waste liquid and washing liquid) in the cooking process are output. exist figure 1 In the shown structure, the discharge, liquid supply and cleaning device includes a product receiving device (not shown in the figure), a liquid receiving distribution device and one or more liquid processing devices (not shown in the figure). Here, the product receiving device includes a product receiving mechanism and a moving device, and the product receiving device is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com