Polyamide-aluminum cold-stamping formed medicine packaging composite film

A technology of cold stamping and polyamide, applied in the field of composite film for pharmaceutical packaging, which can solve problems such as separation layer and aluminum foil layer fracture, achieve the effect of reducing production cost, simple composite process, and suitable for popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

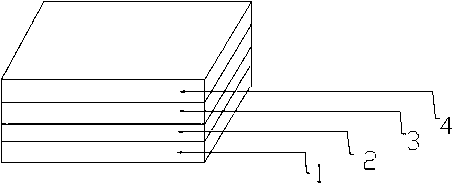

[0017] Such as figure 1 As shown, a polyamide-aluminum cold stamping composite film for pharmaceutical packaging, including a polyamide layer 1, an aluminum foil layer 3 and a heat-sealing coating 4 arranged in sequence, between the polyamide layer 1 and the aluminum foil 3 layers A composite adhesive layer 2 is provided; the polyamide layer 1 made of PA6 is used as a protective layer to block external water vapor, oxygen, light and other factors that may cause drug quality deterioration.

Embodiment 2

[0019] Such as figure 1 As shown, the polyamide layer 1 and the aluminum foil layer 3 are composited together, and the heat-sealing coating 4 is 101-polyurethane adhesive, and the entire composite film and the substrate material are bonded by cold stamping, and it is also applicable to capsules, tablets, etc. cover packaging.

Embodiment 3

[0021] Such as figure 1 As shown, the thickness of the composite film is 20-25um, which can save materials while meeting high transparency and high barrier performance to water vapor, oxygen and light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com