Heat insulation component for heat control of a Mars landing machine, and manufacturing method thereof

A technology for thermal insulation components and landers, which is applied in the direction of aerospace vehicle heat protection devices, aerospace safety/emergency devices, etc., to achieve the effects of weight reduction, excellent heat insulation performance, and resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention are described in detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation modes and concrete operation procedures. It should be pointed out that for those skilled in the art, without departing from the concept of the present invention, several modifications and improvements can be made, which all belong to the protection scope of the present invention.

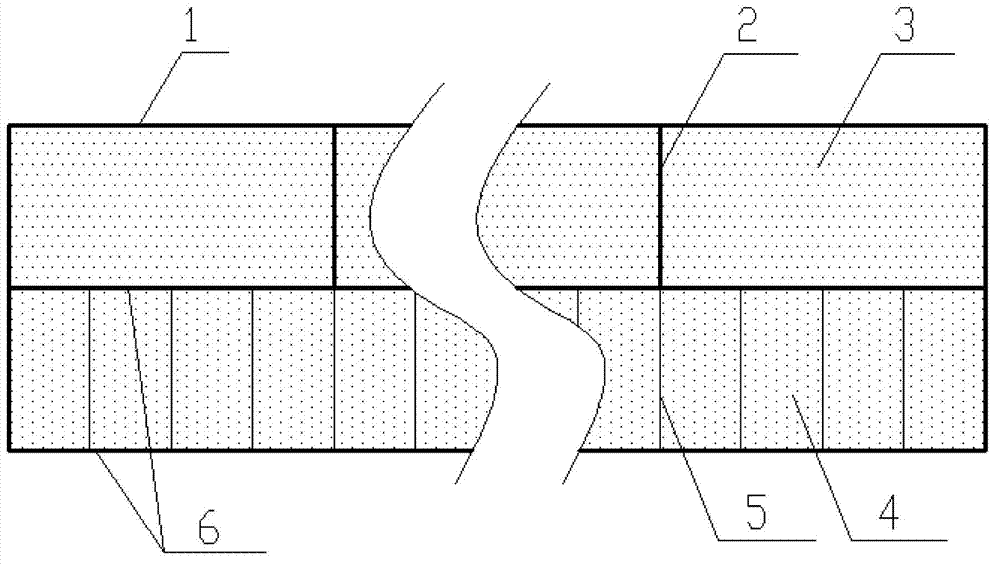

[0033] like figure 1 As shown, this embodiment first provides a thermal insulation assembly for thermal control of a Mars lander, including a thin layer structure 1, a structural support 2, a first aerogel block 3, and a second aerogel block 4. Honeycomb 5 and skin 6; the honeycomb core of the honeycomb is filled with the second aerogel block 4, and the honeycomb 5 is sandwiched between the upper and lower skins 6 to form a honeycomb panel. The skin 6 is bonded by a high temperature re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com