Automatic correction constant speed constant tension rewinding machine

A technology for automatic deviation correction and rewinding machine, applied in the field of rewinding machines, can solve the problems of inability to use polytetrafluoroethylene tape to roll, low production efficiency, uneven adhesion, etc., to improve product quality and production efficiency, rack High utilization rate and the effect of solving excessive stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

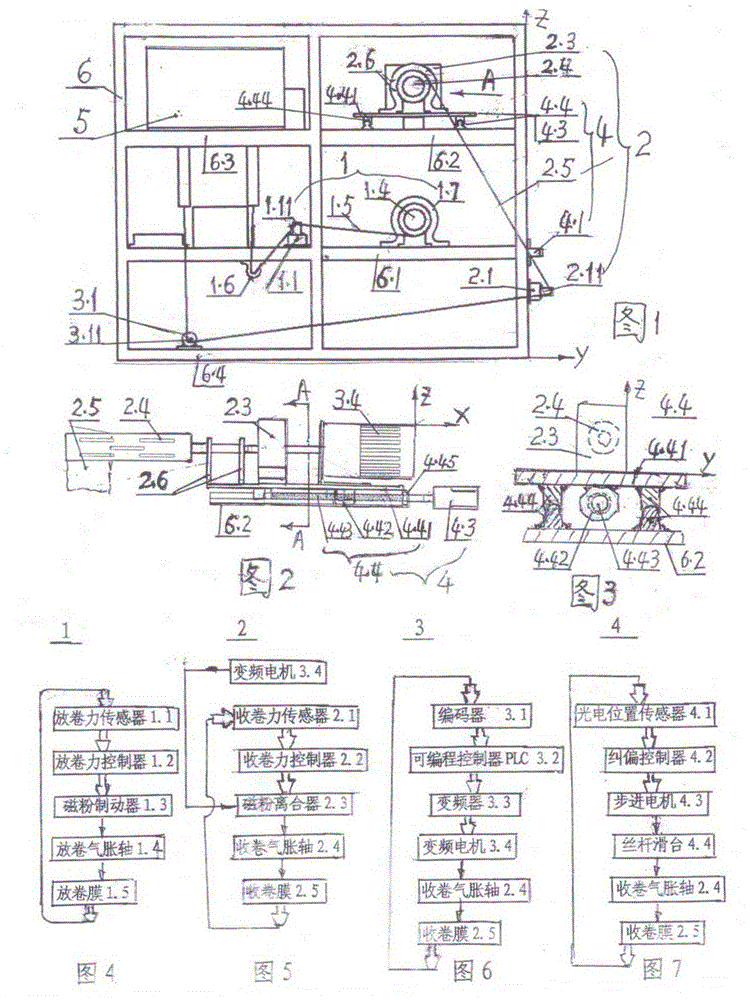

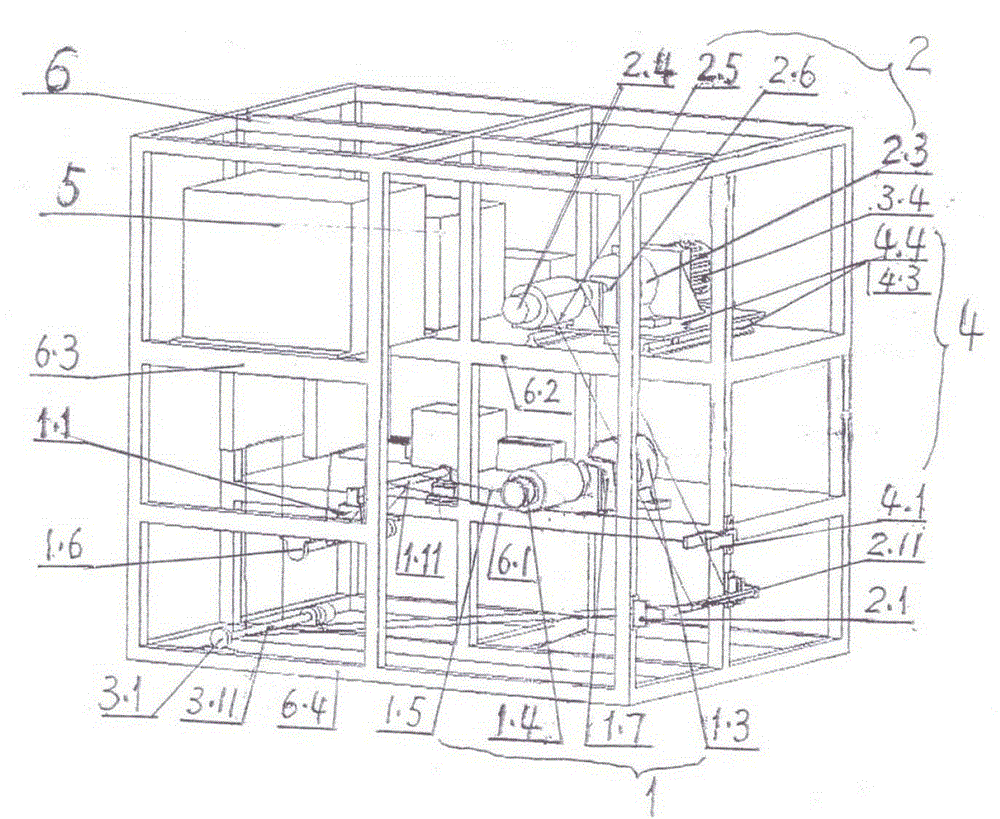

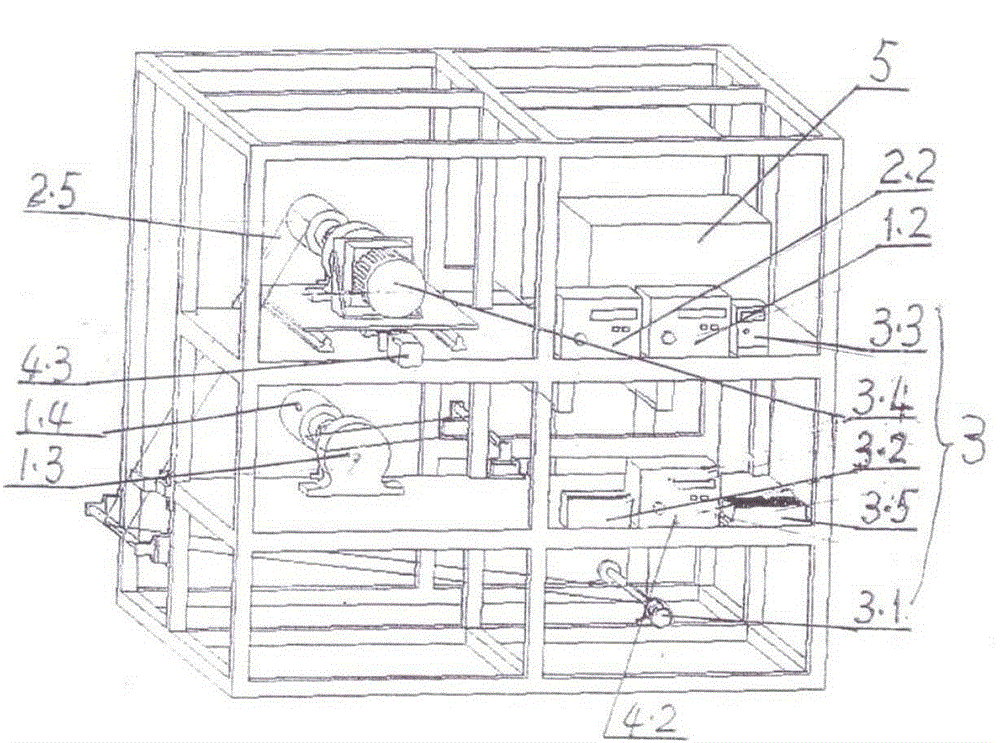

[0022] In this embodiment, the automatic deviation-correcting constant-speed and constant-tension rewinding machine is used for processing polytetrafluoroethylene tapes, and consists of the following components:

[0023] See figure 1 , at the unwinding end of the film processing device 5, an unwinding tension control device 1 is set, which consists of the following: see Figure 8 , the output controllable damping magnetic powder brake 1.3 fixed on the right middle frame 6.1 of the frame 6, the cantilever type unwinding air shaft 1.4 connected with the magnetic powder brake transmission, and the support between the magnetic powder brake 1.3 and the unwinding air shaft 1.4 The double bearing seat 1.7 is placed on the cantilever at the outer end of the unwinding air expansion shaft. See figure 1 , Figure 8 , the unwinding film 1.5 outside the unwinding air shaft passes through the unwinding force sensor roller 1.11 fixed on the left middle frame of the frame, the unwinding gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com