New preparation method for anthelmintic fenbendazole

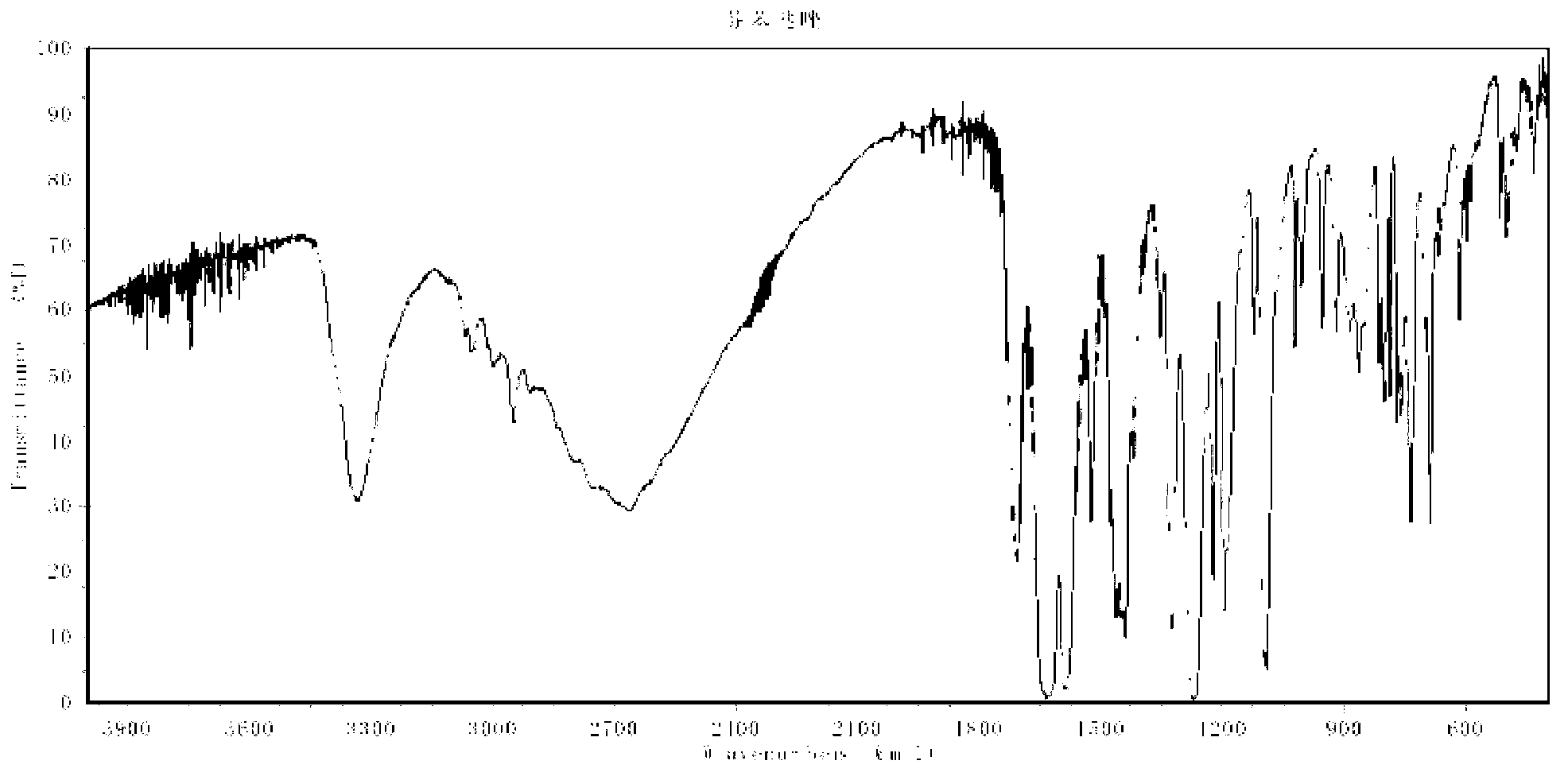

A kind of technology of fenbendazole and new method, applied in the field of preparation of fenbendazole, can solve the problems of low condensation yield and the like, and achieve the effects of high quality, simple and efficient new synthesis process and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

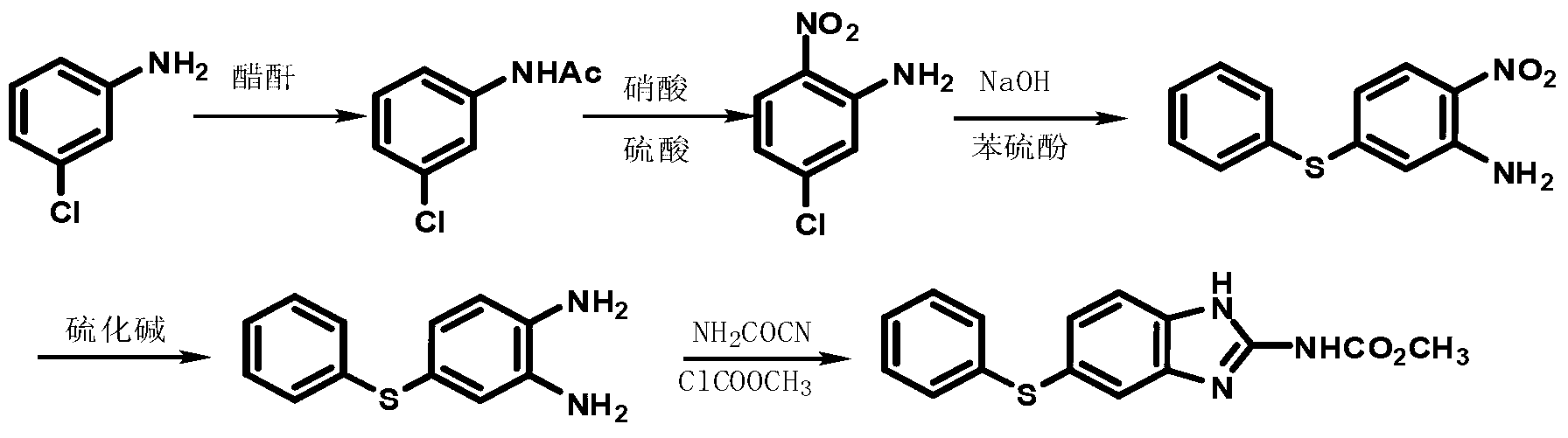

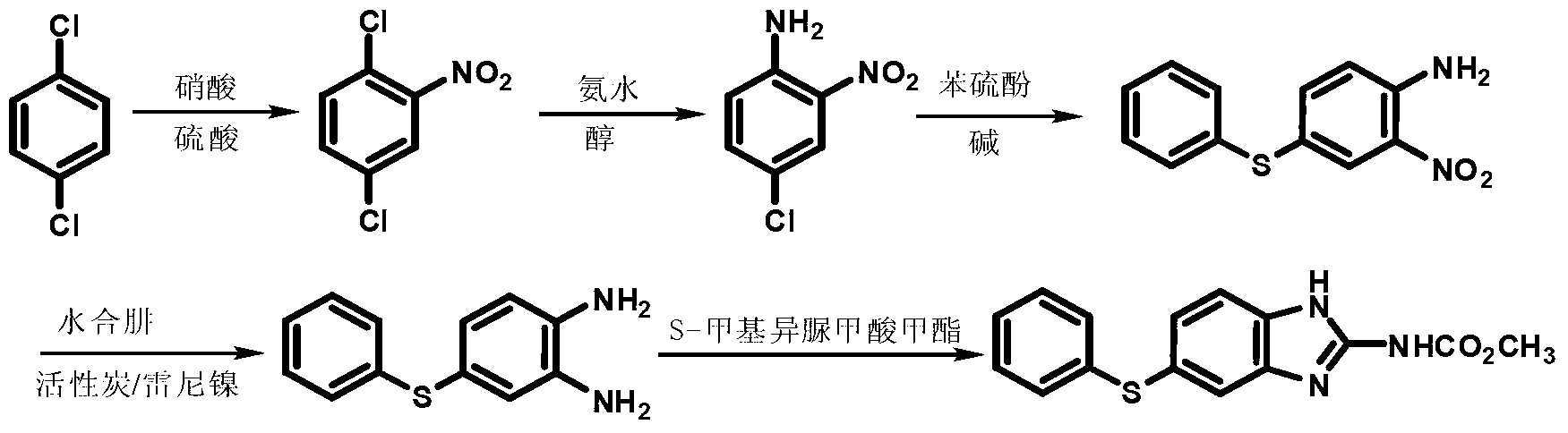

Method used

Image

Examples

Embodiment 1

[0033] Step 12, the preparation of 4-dichloronitrobenzene

[0034] In a 500ml four-necked flask with a thermometer and a stirring device, start stirring, add 100.0g m-dichlorobenzene, 0.5 times the weight ratio of concentrated sulfuric acid, drop nitric acid in a molar amount that is 1.05 times m-dichlorobenzene, and control the dropping temperature at 10-15°C, after the dropwise addition is completed, keep the temperature at 10-15°C for 3 hours, follow the reaction by HPLC, remove the lower waste acid layer, add 100g of 15% sodium carbonate aqueous solution, stir and wash, and separate the lower layer to obtain 2,4- Dichloronitrobenzene 127.0g was directly used in the next step reaction. This step yield is 97.2%, and content is 98.1%.

[0035] Step 22 - Preparation of nitro-5-chloroaniline

[0036] Add 250.0g of 2,4-dichloronitrobenzene obtained in the previous step into a 1000ml autoclave, 2.5 times the weight ratio of 2,4-dichloronitrobenzene toluene, 12 times the weight ...

Embodiment 2

[0045] Step 1 Preparation of 2,4-dichloronitrobenzene

[0046] In a 500ml four-neck flask equipped with a thermometer and a stirring device, start stirring, add 100.0g m-dichlorobenzene, 0.9 times the weight ratio of concentrated sulfuric acid, and the molar amount is 1.1 times m-dichlorobenzene nitric acid, and keep warm at 5-10°C After 3 hours, HPLC traced the reaction to be complete. The lower waste acid layer was separated, and 100 g of 5% sodium hydroxide aqueous solution was added to stir and wash. The lower layer was separated to obtain 125.0 g of 2,4-dichloronitrobenzene, which was directly used in the next reaction. This step yield is 95.7%, and content is 98.7%.

[0047] The preparation of step 2 2-nitro-5-chloroaniline

[0048] In a 1000ml autoclave, add 100.0g of 2,4-dichloronitrobenzene obtained in the previous step, methanol with a weight ratio of 3.5 times 2,4-dichloronitrobenzene, and 10 times 2,4-dichloronitrobenzene Benzene molar amount of ammonia water, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com