High-gloss, high-hardness and spraying-free ABS (acrylonitrile butadiene styrene) plastic modified material and preparation method thereof

A modified material and high hardness technology, applied in the field of high gloss and high hardness spray-free ABS plastic modified material and its preparation, can solve the problems of low production efficiency, limited application, increased production cost, etc., and achieve strong scratch resistance , High degree of blackness, not easy to be scratched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

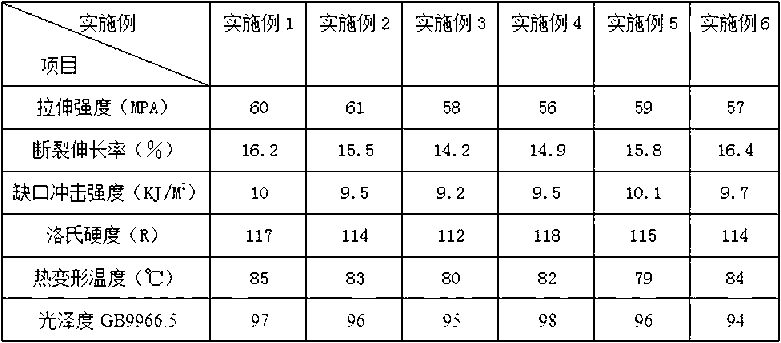

Examples

Embodiment 1

[0077] High-gloss high-hardness spray-free ABS plastic modified material, which consists of the following raw materials in parts by weight: 55 parts of ABS resin, 15 parts of AS resin, 15 parts of PMMA resin, 0.2 parts of PETS, 0.2 parts of EBS, and 1 part of high-pigment carbon black , Antioxidant 1010 0.2 part, methyl silicone oil 0.1 part.

[0078] The preparation method of the high-gloss high-hardness spray-free ABS plastic modified material of the present embodiment consists of the following steps:

[0079] (1) Put ABS resin, AS resin, PMMA resin, PETS, EBS, high-pigment carbon black, antioxidant 1010, and methyl silicone oil into a high-speed mixer and mix evenly for 3 minutes by weight;

[0080] (2) Put the mixture prepared in step (1) into a parallel twin-screw extruder for melt extrusion at a temperature of 230°C, then cool, air-dry, and pelletize to obtain high-gloss, high-hardness spray-free ABS plastic modified material.

Embodiment 2

[0082] High-gloss high-hardness spray-free ABS plastic modified material, which consists of the following raw materials in parts by weight: 57 parts of ABS resin, 16 parts of AS resin, 17 parts of PMMA resin, 0.25 parts of PETS, 0.25 parts of EBS, and 1 part of high-pigment carbon black , Antioxidant 1076 0.25 parts, methyl silicone oil 0.1 parts.

[0083] The preparation method of the high-gloss high-hardness spray-free ABS plastic modified material of the present embodiment consists of the following steps:

[0084] (1) Put ABS resin, AS resin, PMMA resin, PETS, EBS, high-pigment carbon black, antioxidant 1076, and methyl silicone oil into a high-speed mixer and mix evenly for 4 minutes by weight;

[0085] (2) Put the mixture prepared in step (1) into a parallel twin-screw extruder for melt extrusion at a temperature of 235°C, then cool, air-dry, and pelletize to obtain a high-gloss, high-hardness spray-free ABS plastic modified material.

Embodiment 3

[0087] High-gloss, high-hardness spray-free ABS plastic modified material, which consists of the following raw materials in parts by weight: 59 parts of ABS resin, 17 parts of AS resin, 20 parts of PMMA resin, 0.3 parts of PETS, 0.3 parts of EBS, and 1.5 parts of high-pigment carbon black , Antioxidant 168 0.3 part, methyl silicone oil 0.15 part.

[0088] The preparation method of the high-gloss high-hardness spray-free ABS plastic modified material of the present embodiment consists of the following steps:

[0089] (1) Put ABS resin, AS resin, PMMA resin, PETS, EBS, high-pigment carbon black, antioxidant 168, and methyl silicone oil into a high-speed mixer and mix evenly for 5 minutes by weight;

[0090] (2) Put the mixture prepared in step (1) into a parallel twin-screw extruder for melt extrusion at a temperature of 240°C, then cool, air-dry, and pelletize to produce high-gloss, high-hardness spray-free ABS plastic modified material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com