Liquid crystal composition with low threshold and high response speed

A liquid crystal composition, fast response technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of increasing device drive voltage, affecting display effect, slow response speed, etc., and achieve the effect of fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0122] The preparation of liquid crystal composition all adopts following method:

[0123] Using the thermal dissolution method commonly used in the industry, first use a balance to weigh each monomer in the liquid crystal composition by weight percentage, add the liquid first and then the solid in the order of addition, there is no specific requirement for the order of solid addition, and heat and stir at 100°C The components are melted and mixed evenly, then filtered, degassed, and finally packaged to obtain the target sample. In addition, it is also possible to mix the solutions of each component in an organic solvent, such as acetone, chloroform, methanol, etc., remove the solvent after thorough mixing, such as by distillation, etc., and then filter, degas, and package The target sample can be obtained.

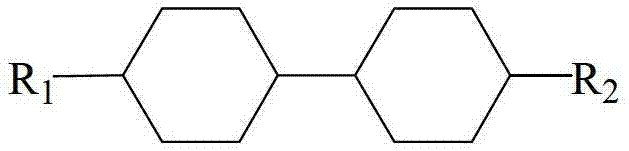

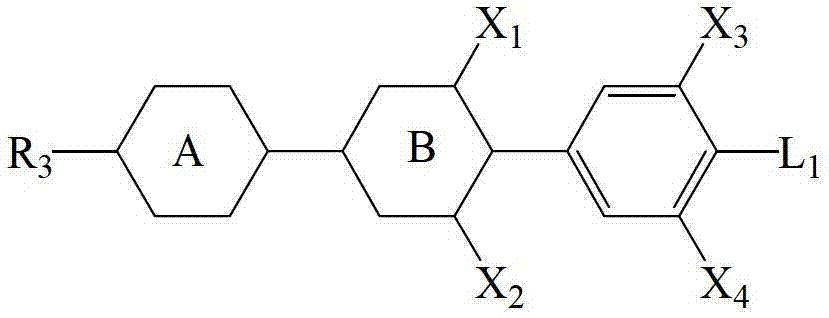

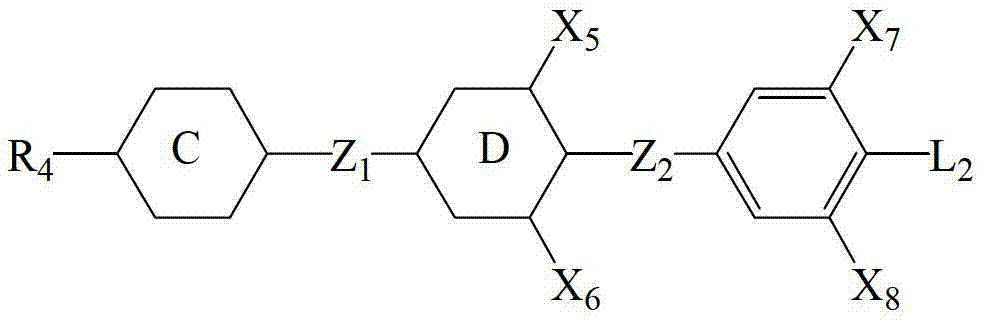

[0124] In this embodiment, the liquid crystal monomer components involved adopt the following notation method:

[0125]

[0126] In this embodiment, the components o...

Embodiment 1

[0129] The components by weight percentage shown in Table 1 are used to prepare the liquid crystal composition, and its performance parameters are shown in Table 1:

[0130] Table 1: The ratio and performance parameters of the liquid crystal composition

[0131]

[0132]

Embodiment 2

[0134] The components by weight percentage shown in Table 2 are used to prepare the liquid crystal composition, and its performance parameters are shown in Table 2:

[0135] Table 2: The ratio and performance parameters of the liquid crystal composition

[0136]

[0137]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com