Method for extracting molybdenum from molybdenum-containing high-concentration acidic lixivium and application of extraction agent

An acid leachate, high-concentration technology, applied in the field of molybdenum extraction, can solve the problems of complex process, high cost, and inexhaustible removal of impurities when extracting molybdenum, and achieves the effects of simple operation, high recovery rate, and reduction of neutralization procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

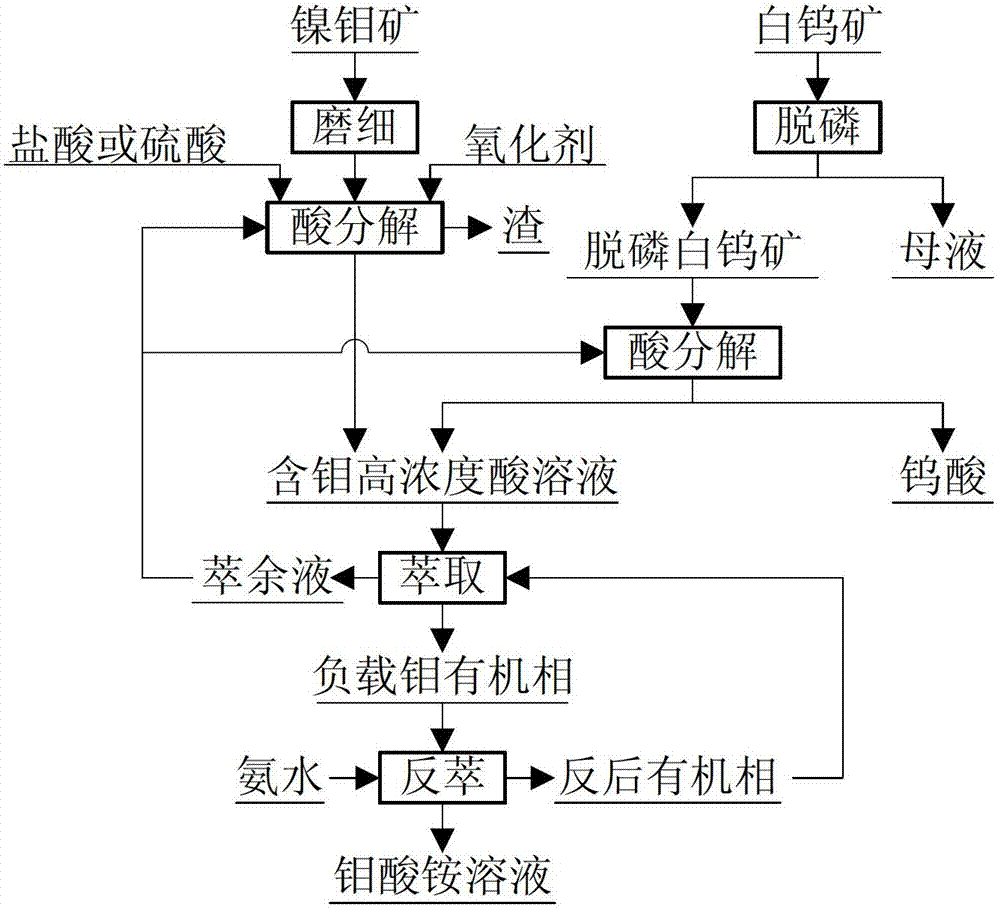

[0029] according to figure 1 The process flow is operated;

[0030] The feed liquid is dephosphorylated scheelite acid decomposition liquid, containing molybdenum 8.328g / L, free H + The concentration is 6.189mol / L;

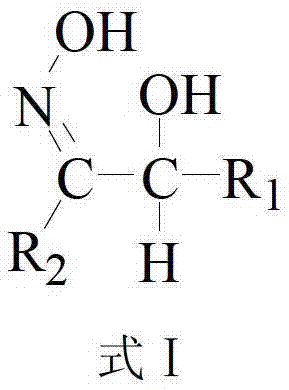

[0031] The organic phase is 10% extractant + 5% TBP + sulfonated kerosene;

[0032] A separatory funnel was used for single-stage extraction, the extraction ratio (O / A) = 1 / 1, the extraction time was 10 minutes, the temperature was 30°C, and the phase separation was 1 minute. The raffinate contained molybdenum 1.252g / L, and the molybdenum extraction rate reached 85.0 %.

Embodiment 2

[0034] according to figure 1 The process flow is operated;

[0035] The feed liquid is dephosphorylated scheelite acid decomposition liquid, containing molybdenum 8.328g / L, free H + The concentration is 6.189mol / L;

[0036] The organic phase is 10% extractant + 5% + 85% sulfonated kerosene;

[0037] A separatory funnel was used for single-stage extraction, the extraction ratio (O / A)=1 / 1.5, the extraction time was 10 minutes, the temperature was 30°C, and the phase separation was 1 minute. The raffinate contained molybdenum 1.362g / L, and the molybdenum extraction rate reached 89.1 %.

[0038] The above-mentioned loaded organic phase was back-extracted with 12.5% ammonia water according to the ratio (O / A)=4:1, the stripping time was 10min, the temperature was 40°C, the stripping solution contained molybdenum 32.58g / L, and the molybdenum stripping rate reached 73.2%.

Embodiment 3

[0040] according to figure 1 The process flow is operated;

[0041] The feed liquid is scheelite middle ore dephosphorization mother liquor, containing 0.374g / L molybdenum, 5.451g / L phosphorus, free H + The concentration is 0.912mol / L;

[0042] The organic phase is 10% extractant + 5% TBP + sulfonated kerosene;

[0043] Use a separatory funnel for single-stage extraction, the extraction ratio (O / A)=1 / 1, the extraction time is 10min, the temperature is 30°C, and the phase is separated for 1min. The raffinate contains 0.0092g / L of molybdenum and 5.385g / L of phosphorus. L, the molybdenum extraction rate reaches 97.5%, and the phosphorus extraction rate is only 1.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com