Composite heat-insulating superimposed sheet

A composite thermal insulation and laminated board technology, applied in thermal insulation, building components and other directions, can solve the problems of different life expectancy of thermal insulation and structure, low thermal insulation fire rating, cracking, etc., to achieve good fire safety, quality assurance, and improve the effect of construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

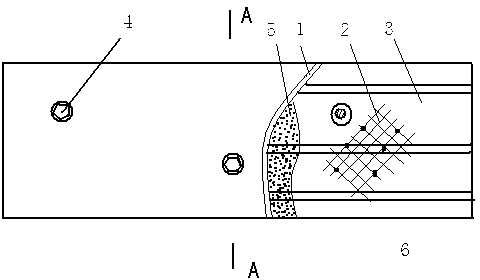

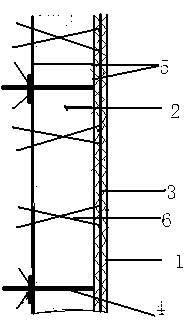

[0015]As shown in the figure is a specific embodiment: a composite thermal insulation laminated board integrated with the main structure concrete, including polystyrene (extrusion plastic) board 2, connecting steel wire 6, steel wire mesh 3, lightweight composite concrete layer 1, The interface agent layer 5 and the anchor bolt 4, the surface of the polystyrene (extruded) board 2 is provided with an interface agent protective layer 5, one side of the polystyrene (extruded) board 2 is covered with a steel wire mesh 3, and the high-strength connecting steel wire 6 is inclined Insert the polystyrene (extruded plastic) board 2, one end of the connecting steel wire 6 is welded to the steel wire mesh 3, and the length of the other end protruding out of the polystyrene (extruded plastic) board is not less than 25 mm, and the lightweight composite concrete layer 1 wraps the steel wire mesh 3 And connected with polystyrene (extruded plastic) board, the thickness of the lightweight compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com