Method for determining bulk density of field core sample from asphalt pavement

A technology of bulk density and determination method, which is applied in the field of determination of bulk density, can solve the problems of inaccurate density measurement, many open pores on the side wall of the core sample, and difficult to clean, so as to achieve accurate bulk density and eliminate open pores the effect of the influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Measuring the bulk density of the core sample of asphalt concrete

[0023] 1.1 Use a drill with an inner diameter of about 80-83mm to take out a core sample from the road;

[0024] 1.2 After cutting both ends of the core sample by 2mm with a cutting machine, wrap the core with absorbent paper, and then place it in a vacuum container for continuous suction for 15 minutes to absorb the water in the absorbent;

[0025] 1.3 Use an electronic balance with a measuring range of 4000g and a sensitivity of 0.01g to weigh the air weight of the dry test piece m1=2522.6g;

[0026] 1.4 Melt the paraffin to 110~115℃, use a dropper to drop the wax into the visible holes on the surface of the core;

[0027] 1.5 After the wax is cooled, use a scraper to scrape the wax exposed on the surface of the core piece from the wax filling point, and scrape it flat along the surface, and weigh the total weight of the core piece and the wax filling m2=2531.9g;

[0028] 1.6 Reheat the paraffin to 60...

Embodiment 2

[0036] Example 2: Comparison of the wax dropping method of the present invention and the original wax sealing method

[0037] After the completion of the construction, a total of 34 core samples were drilled on site, 19 of which were measured using the method of the present invention, and the remaining 15 were measured using the original test method. The test results are shown in Table 1 and Table 2 respectively. Shown.

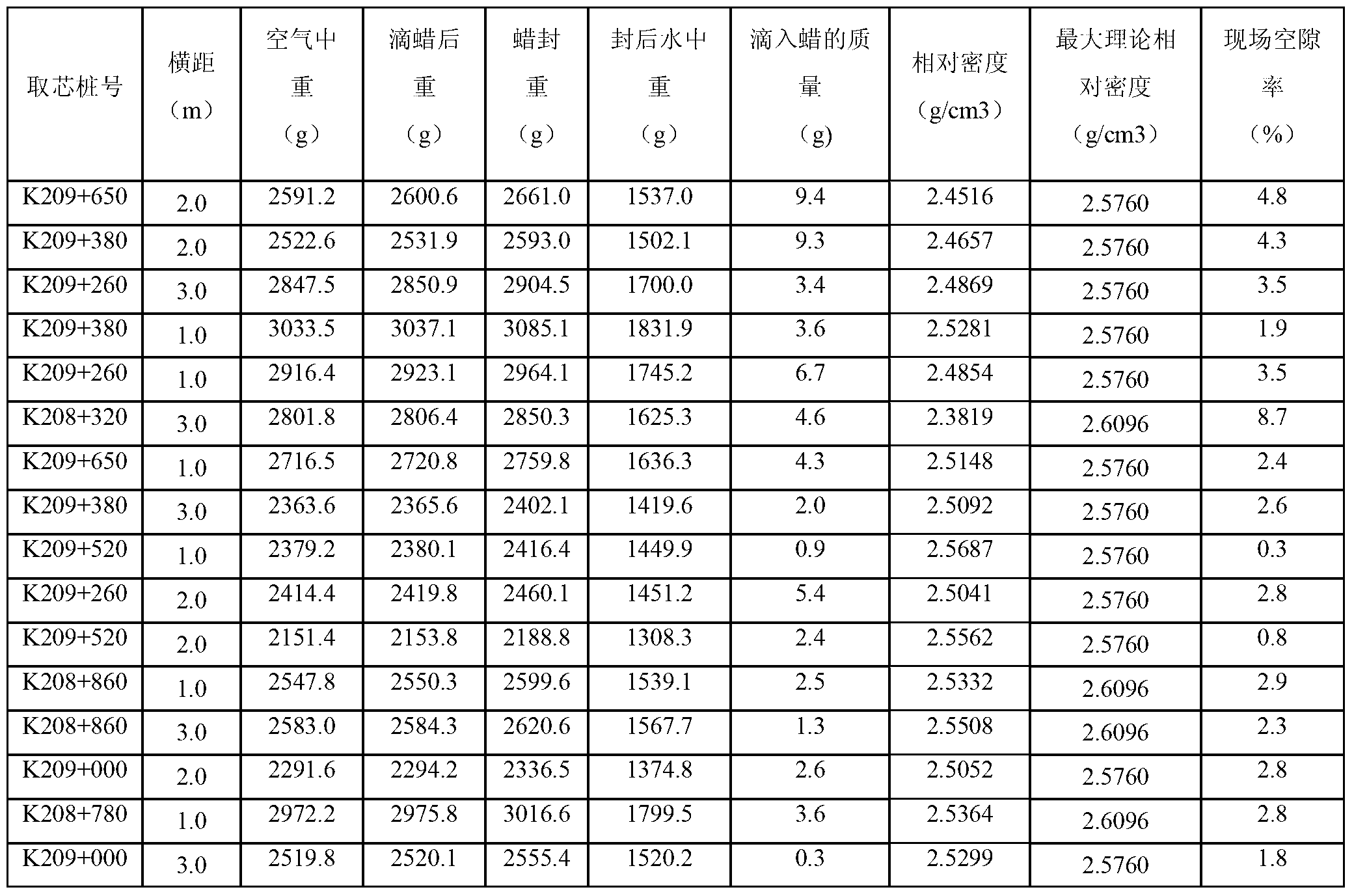

[0038] Table 1 Measurement results of the method of the present invention

[0039]

[0040]

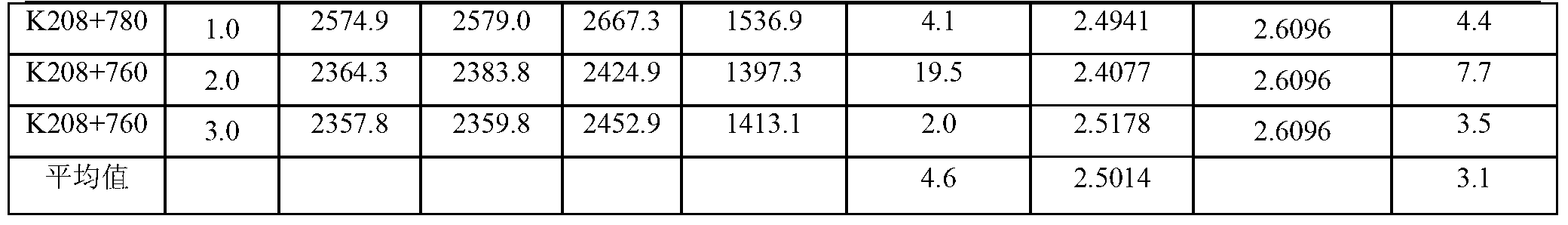

[0041] Table 2 Measurement results of the original wax sealing method

[0042]

[0043] The maximum theoretical relative density in Table 1 and Table 2 are all on the day of paving the surface layer, taken at the construction site, and measured using the vacuum method in the "Highway Engineering Asphalt and Asphalt Mixture Test Regulations" (JTG E20—2011) (On-site void ratio=1-bulk volume relative density / maximum theoretical relative density). Through the comparison of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com