Comprehensive experimental device for cutting jet supporting

An experimental device and jet technology, applied in educational appliances, instruments, teaching models, etc., to achieve the effects of easy assembly, simple structural design, and satisfying experimental needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

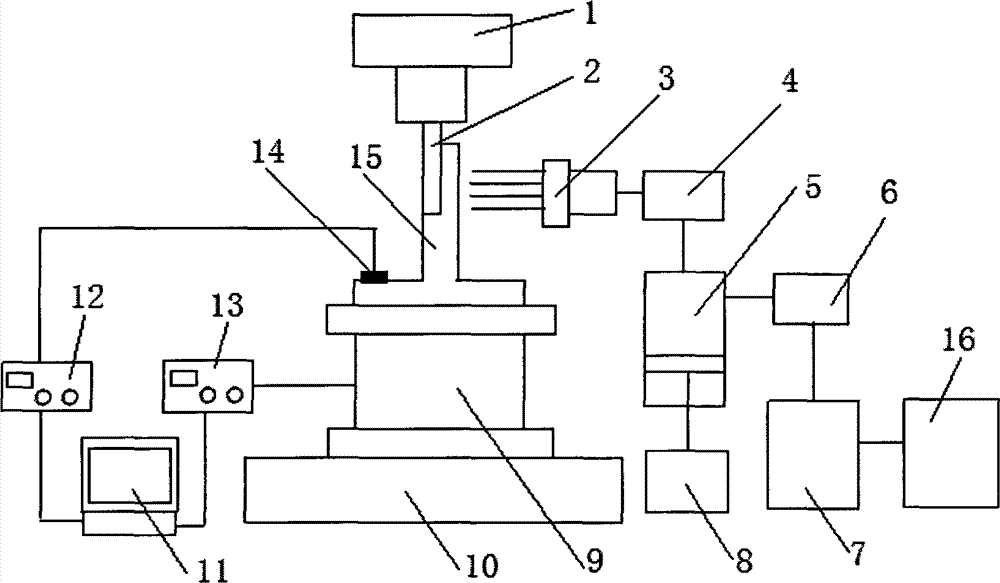

[0014] according to figure 1 , The comprehensive experimental device for cutting jet support is mainly composed of cavitation jet generating device, cutting force measuring device and vibration measuring device. The cavitation jet generating device includes a water tank 16, a motor 8, a high pressure pump 7, a pressure holding control cylinder 5, a cavitation generator 6, a pulse generator 4 and a nozzle 3, etc. The medium water is filtered from the water tank 16, pressurized by the high-pressure pump 7, and sprayed out from the nozzle 3 after the action of the cavitation generator 6 and the pulse generator 4. The impact force generated by the jet acts on the surface of the predetermined workpiece to provide Auxiliary support. The cutting force measuring device includes a dynamometer 9, an amplifier 13, a computer 11, and the like. The workpiece 15 is fixed on the workbench of the dynamometer 9 by screws, the base of the dynamometer 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com