Stack type baseplate structure

A stacked, substrate technology, applied in the direction of printed circuits, electrical components, sealed enclosures, etc. where non-printed electrical components are connected, it can solve the problems of non-compliance with economic costs, difficult process control, etc., to reduce circuit short circuit or abnormality , The effect of improving production efficiency and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

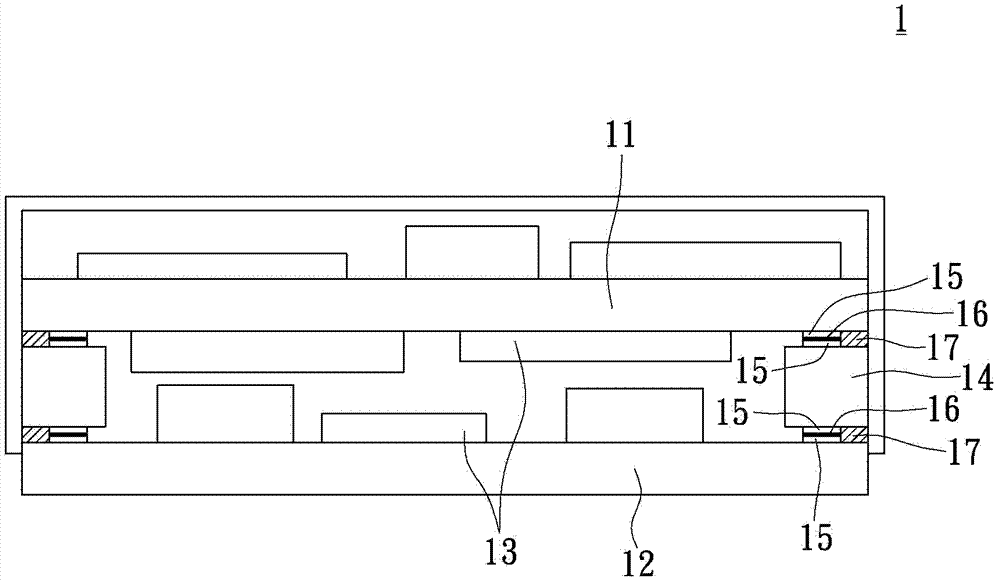

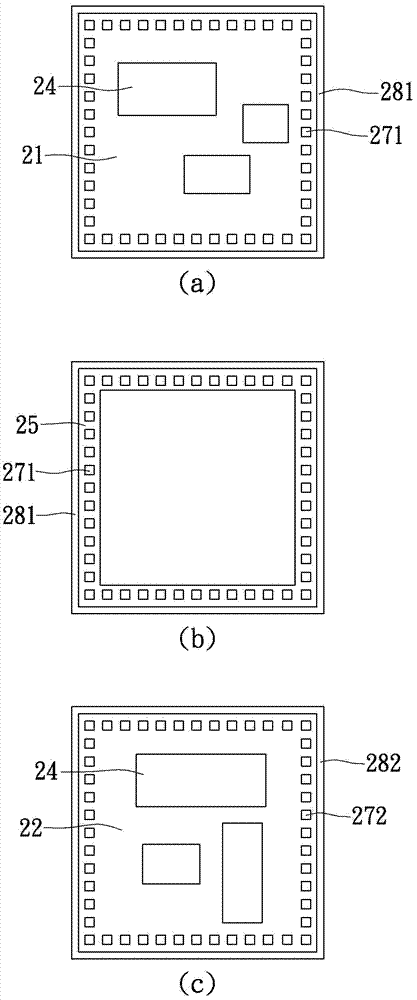

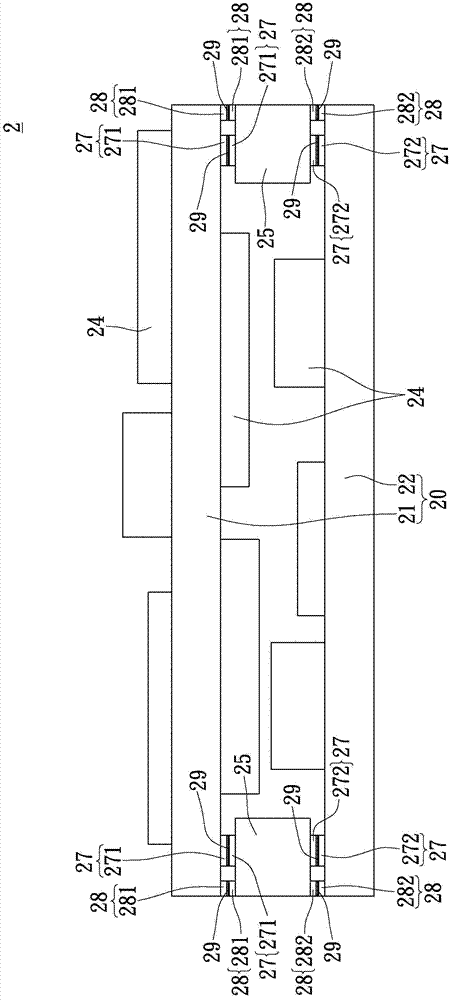

[0054] Please refer to figure 2 and image 3 As shown, a stacked substrate structure 2 includes a substrate unit 20 , a first frame 25 , a conductor unit 27 and a barrier unit 28 . First, the substrate unit 20 has a first substrate 21 and a second substrate 22, such as figure 2 Shown in (a) is the first substrate 21, figure 2 Shown in (c) is the second substrate 22, the first substrate 21 is located on the top of the second substrate 22, the first substrate 21 and the second substrate 22 respectively have a plurality of electronic components 24, the first substrate 21 and the second substrate 22 may be a printed circuit board.

[0055] Wherein, a first frame body 25 can be arranged between the first substrate 21 and the second substrate 22, such as figure 2Shown in (b) is the first frame body 25, that is to say, the first substrate 21 is stacked above the first frame body 25, and the second substrate 22 is arranged below the first frame body 25 to form a stacked struc...

no. 2 example

[0066] Please refer to Figure 7 and Figure 8 As shown, the stacked substrate structure 2 of the second embodiment can be extended from the first embodiment, that is, the structure of the first embodiment can continue to stack a layer of substrates and frames, so the bottom of the second substrate 22 can be A second frame body 26 and a third substrate 23 are provided, so that the stacked substrate structure 2 is formed by stacking three layers of substrates and two frames. Such as Figure 7 (a) is the first substrate, Figure 7 (b) shows the first frame, Figure 7 (c) is the second substrate, Figure 7 (d) is the second frame, Figure 7 (e) shows the third substrate.

[0067] Furthermore, a second conductor 272 and solder 29 can be provided on the lower side of the second substrate 22 to connect to the second frame 26, and the second frame 26 is then connected to the third substrate 23 through the third conductor 273 and solder 29. , forming a layered structure. Where...

no. 3 example

[0072] Please refer to Figure 9 and Figure 10 As shown, the stacked substrate structure 2 of the third embodiment includes a first substrate 21 , a first frame 25 , a plurality of first conductors 271 and a first barrier 281 . Such as Figure 9 (a) shows the first substrate, Figure 9 (b) shows the first frame. Firstly, the first substrate 21 can be a printed circuit board, the first frame body 25 is located on one side of the first substrate 21, the first frame body 25 can be hollow, so it can accommodate the electronic components 24 of the first substrate 21, and The first frame body 25 can have the properties of conduction and signal transmission.

[0073]Among them, a plurality of first conductors 271 are connected to the first substrate 21 and the first frame body 25, and the first conductors 271 are connected to the first conductors on the first frame body 25 through solder 29 (a metal alloy containing tin, silver or copper). The conductors 271 are electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com