Lubricating oil containing sheet magnetic nanometer Fe3O4 particles and preparation method of lubricating oil

A kind of magnetic nano and lubricating oil technology, applied in lubricating composition, petroleum industry, additives and other directions, can solve the problems of low stability, easy precipitation, corrosion, etc., to improve anti-friction and anti-wear performance, good dispersibility and The effect of stability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

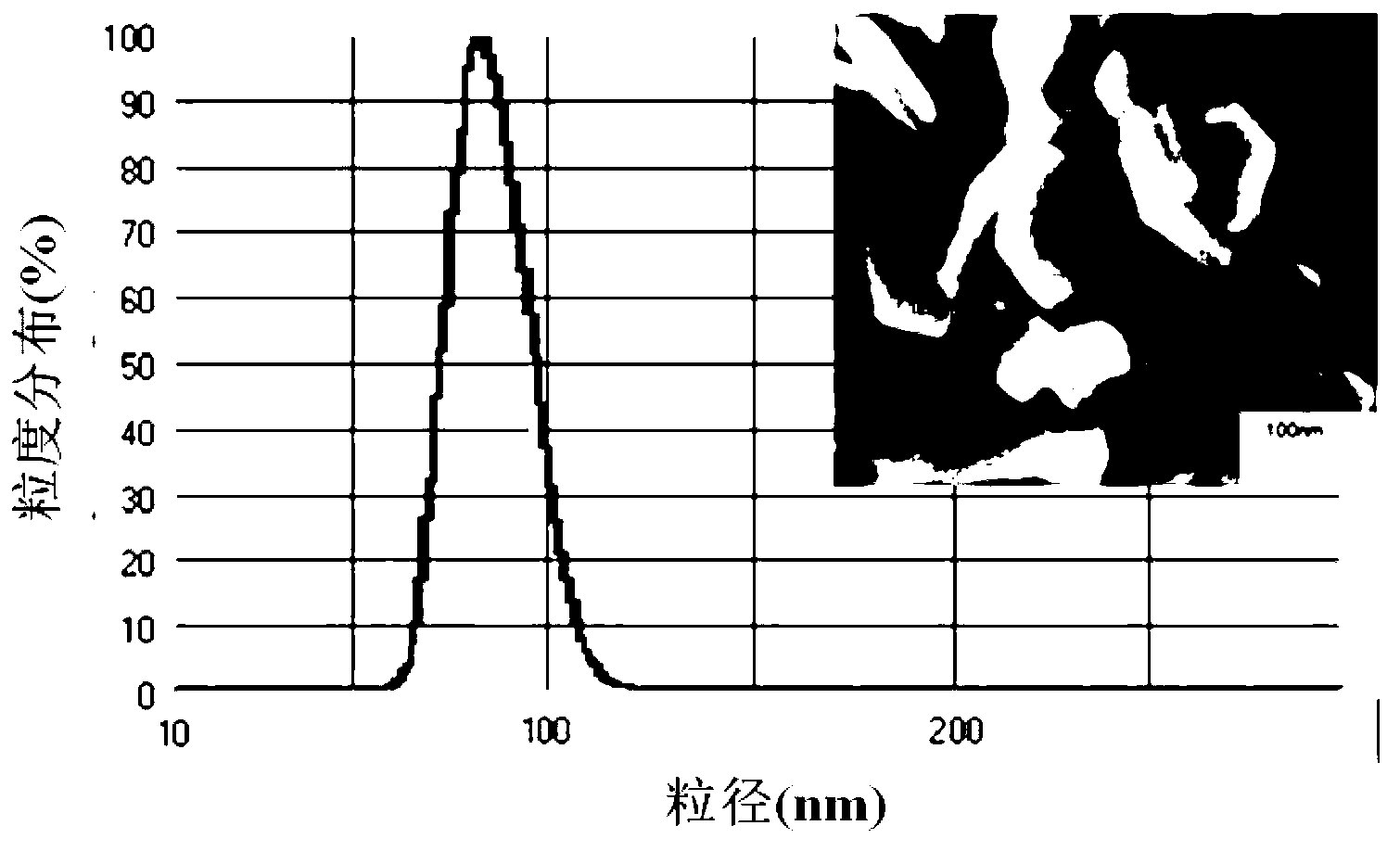

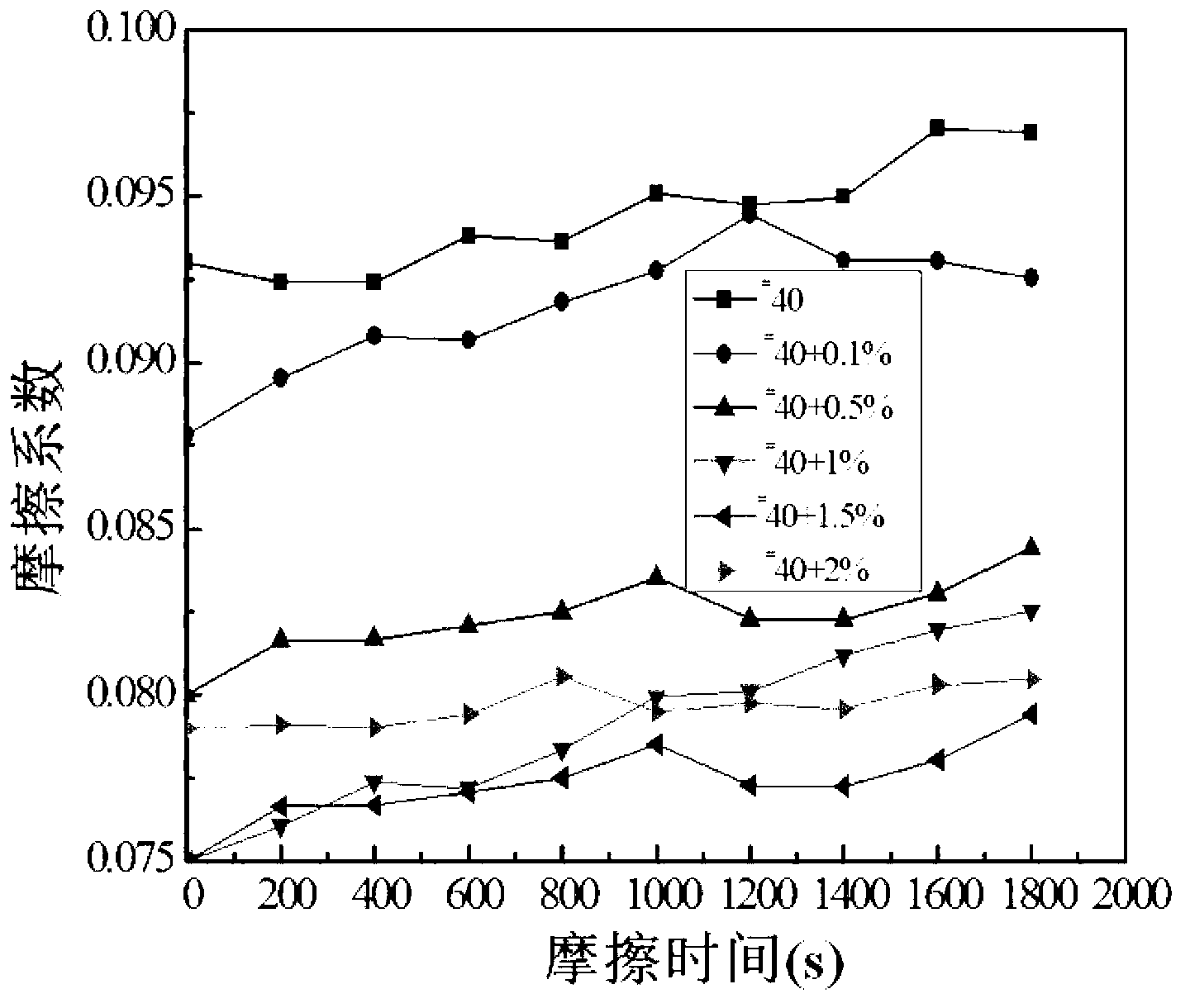

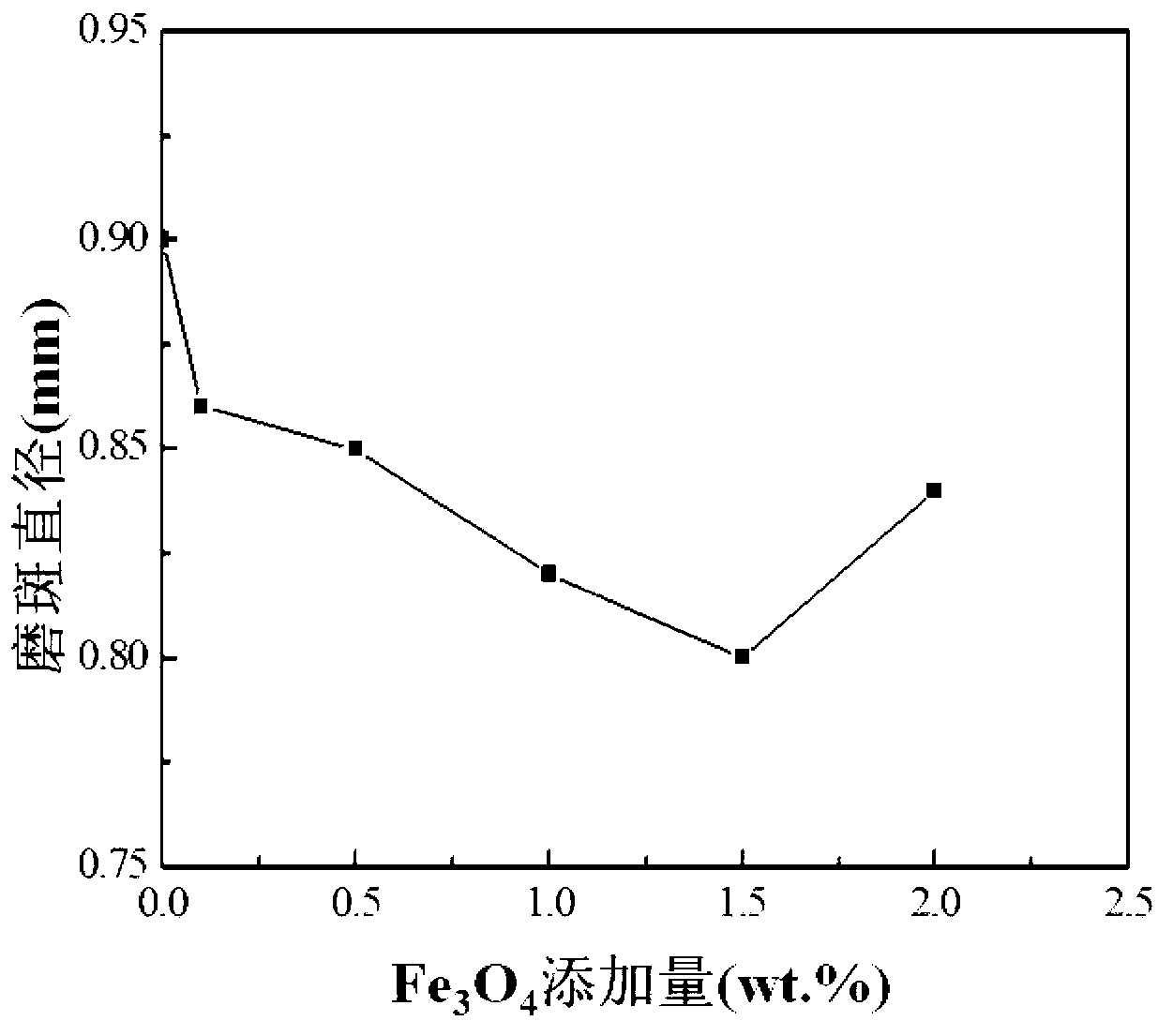

[0028] Preparation of Flake Magnetic Nano-Fe by Oxidation Co-precipitation Assisted by Weak Magnetic Field 3 o 4 Particles: with FeCl 2 as raw material, NaOH as precipitant, H 2 o 2 as an oxidizing agent, in N 2 Under protection, by controlling the reactant FeCl 2 The concentration is 0.6mol·L -1 And the weak magnetic field intensity is 460Gs to make particle size be 20-70nm, sheet thickness is the flaky magnetic nanometer Fe of 20nm 3 o 4 Particles (for their morphology and particle size see figure 1 ), and then dried in a vacuum oven. The dried nano-Fe 3 o 4 Add 100g of pellets and 300g of deionized water into a beaker to prepare Fe 3 o 4 For suspension of nanopowder, place the beaker in a water bath at 80°C and keep stirring, then add glacial acetic acid solution with a concentration of 1mol / L to the beaker until the pH value drops to 6.9, and finally add 1.3g oleic acid slowly Carry out the coating reaction. After coating, the coated sample was washed with ab...

Embodiment 2

[0030] The difference between this embodiment and embodiment 1 is:

[0031] The composition of the lubricating oil contains 0.5% flake magnetic nano-Fe by mass percentage 3 o 4 particles.

Embodiment 3

[0033]The difference between this embodiment and embodiment 1 is:

[0034] The composition of the lubricating oil contains 1.0% flake magnetic nano-Fe by mass percentage 3 o 4 particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com