Polypropylene carbonate paint composition

A polypropylene carbonate and composition technology, applied in the field of polypropylene carbonate coating composition, can solve the problems of inability to achieve low smoke density, inability to develop coating adhesion and durability, etc., and achieve superior economy Feasibility, enhancement of hardness, effect of reducing coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

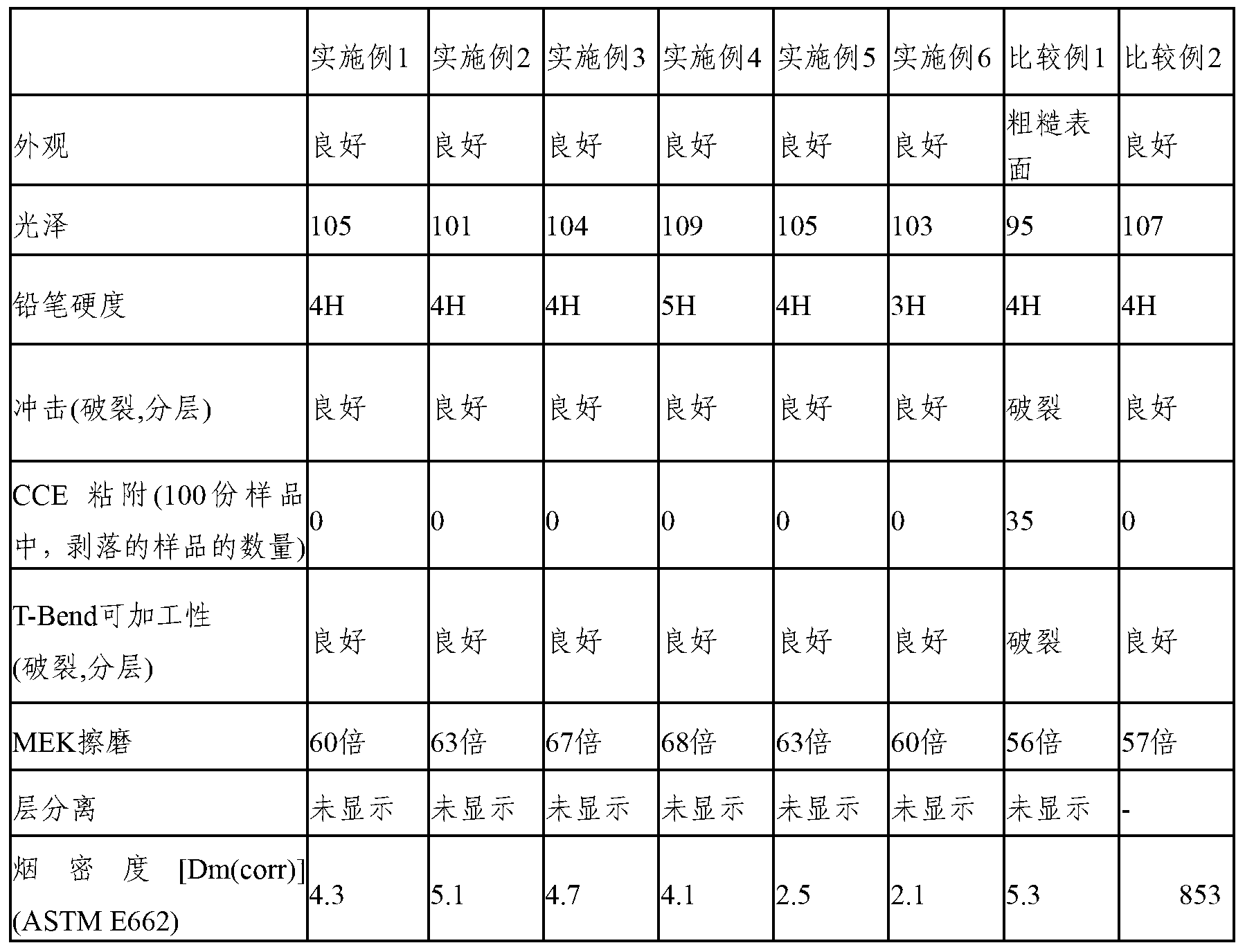

Examples

Embodiment 1

[0044] 100g (25.71wt%) of PPC (GreenPol product, SK Energy Co., Ltd.) containing a hydroxyl group at one end of its molecular chain was placed in a metal can, and its weight-average molecular weight was 100,000g / mol and its glass transition temperature was 35°C, and 200g of solvent was further added After stirring well, PMA and MEK were mixed in the solvent at a volume ratio of 1:1.

[0045] 0.3 g (0.08 wt%) of Organo-Clay (Bentone) was slowly placed in the stirred solution while stirring. Next, after placing glass beads with a diameter of 2 to 3 mm therein, sufficient dispersion was performed for 2 hours using a vibrating type disperser so as to be at a level of 5 μm or less when measured by a grind gage. dispersion. In addition, 68g (17.48wt%) of PPC resin, 10.0g (2.57wt%) of butylated melamine formaldehyde, and 9.5g (2.44wt%) of PMA and MEK mixed in a 1:1 solvent were added to the solution, and then Stir well.

[0046] For dispersion stability, 0.05 g of BYK-143 and 0.1 ...

Embodiment 2

[0051] The same procedure as Example 1 was followed, except that 3 g of HDI trimer was added instead of melamine, and 0.1 g of dibutyltin dilaurate (DBTDL) was added instead of p-toluenesulfonic acid.

Embodiment 3

[0053] The same procedure as Example 1 was carried out, except that PPC with a molecular weight of 50,000 g / mol was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com